Bright alloy steel sand production process

A production process and alloy steel technology, applied in the field of bright alloy steel sand production process, can solve the problems of weakened impact resistance and wear resistance, easy corrosion of the surface layer of forged steel sand, inconsistent internal structure, etc., and achieve excellent impact resistance. and wear resistance, stable and consistent surface structure and internal structure, dust reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

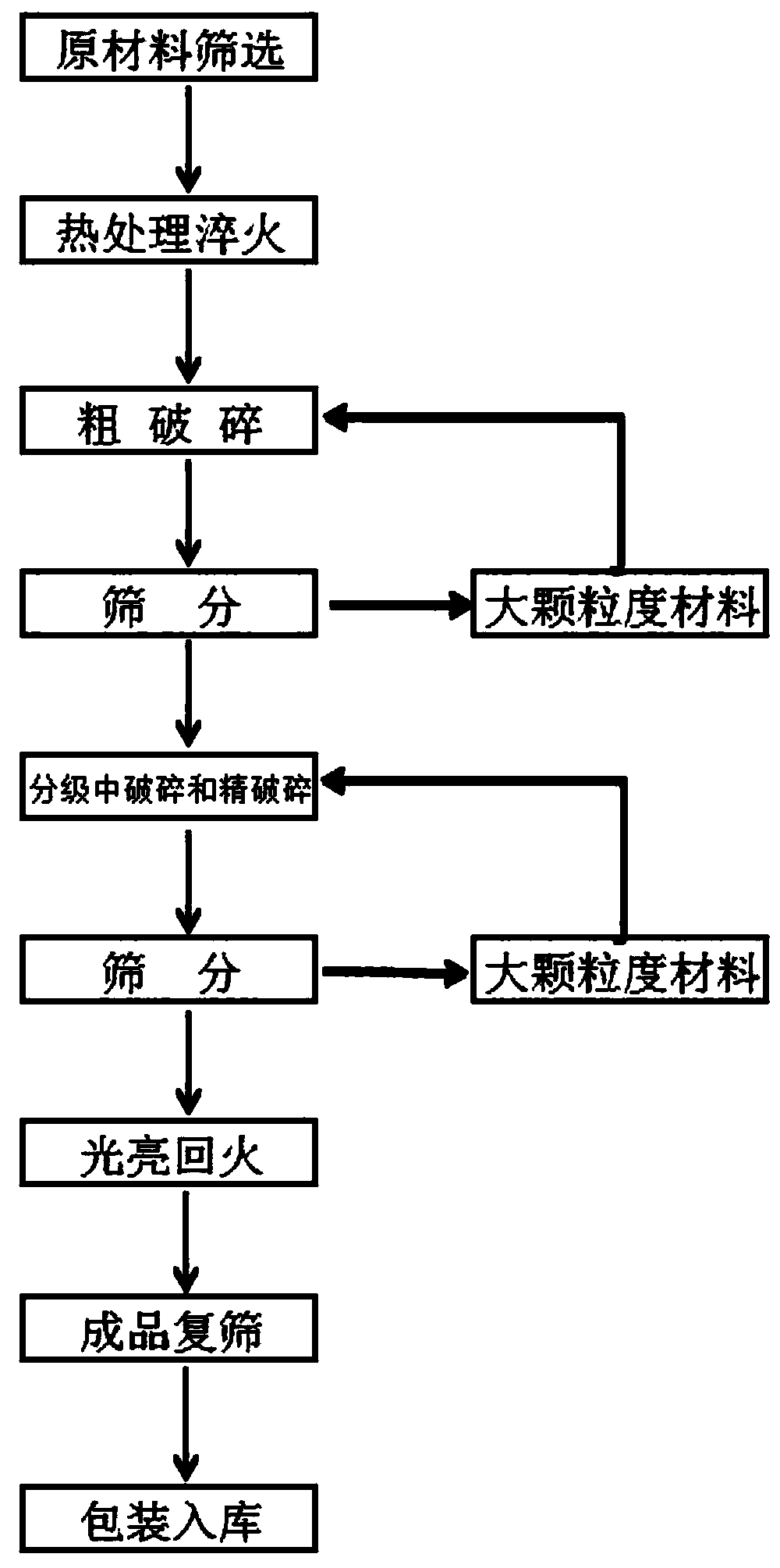

[0041] In order to understand the technical scheme of the present invention more intuitively and completely, the non-limiting feature descriptions are as follows in conjunction with the accompanying drawings of the present invention:

[0042] Such as figure 1 Shown, the production process of bright alloy steel grit comprises the following steps:

[0043] (1) Raw material screening: Classify and collect alloy steel raw materials according to their thickness and size;

[0044] (2) heat treatment quenching: put the raw material into the quenching device for quenching treatment;

[0045] (3) Coarse crushing: put the quenched material into the crusher for crushing;

[0046] (4) Classification crushing and fine crushing: Classification crushing and fine crushing are carried out on the coarsely crushed materials with a classifying crusher, and the crushed materials are screened and collected, and semi-finished products of various particle size models are screened out;

[0047] (5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com