Hot stamp moulded body

A formed body and hot stamping technology, applied in the field of high-strength steel sheets and hot stamped bodies, can solve problems such as difficulty in ensuring tensile strength, and achieve the effects of improving collision resistance, hydrogen embrittlement resistance, and collision resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0163] Next, examples of the present invention will be described. The conditions in the examples are examples of conditions employed to confirm the practicability and effects of the present invention, and the present invention is not limited to the examples of conditions. Various conditions can be employed in the present invention as long as the object of the present invention is achieved without departing from the gist of the present invention.

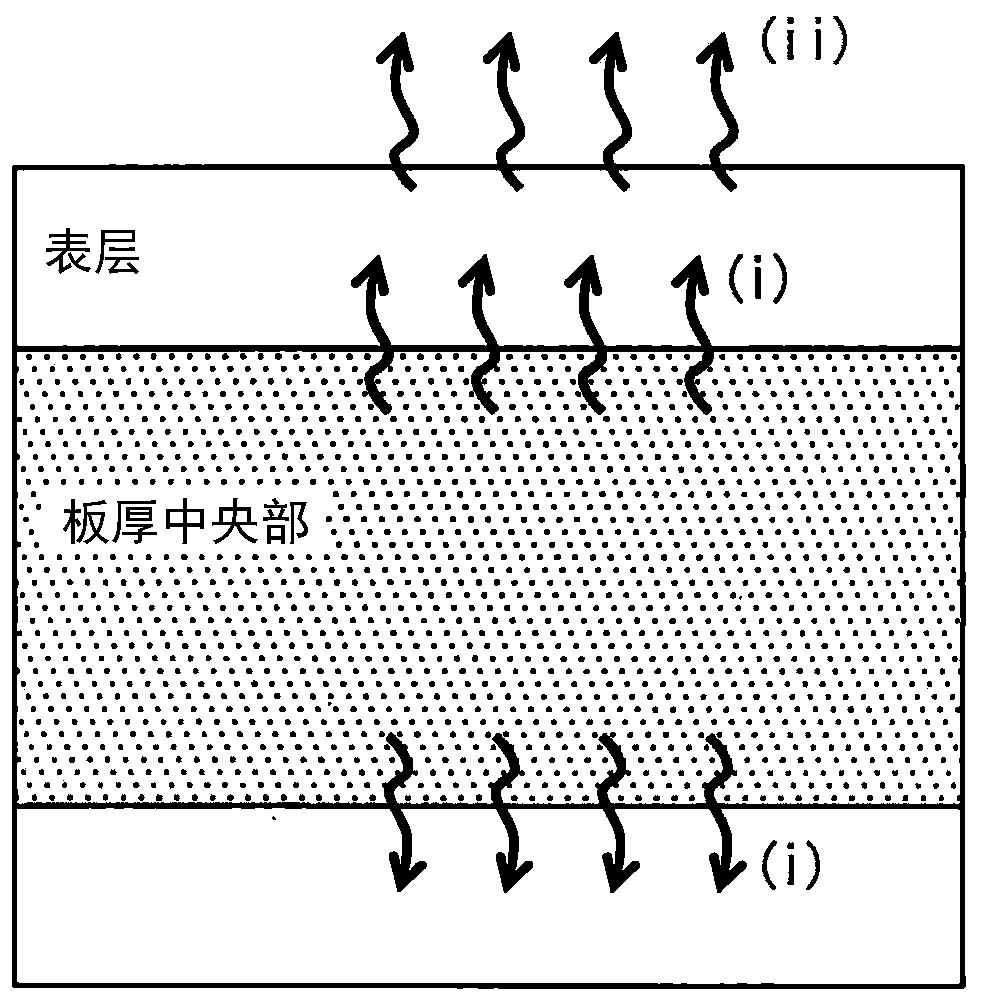

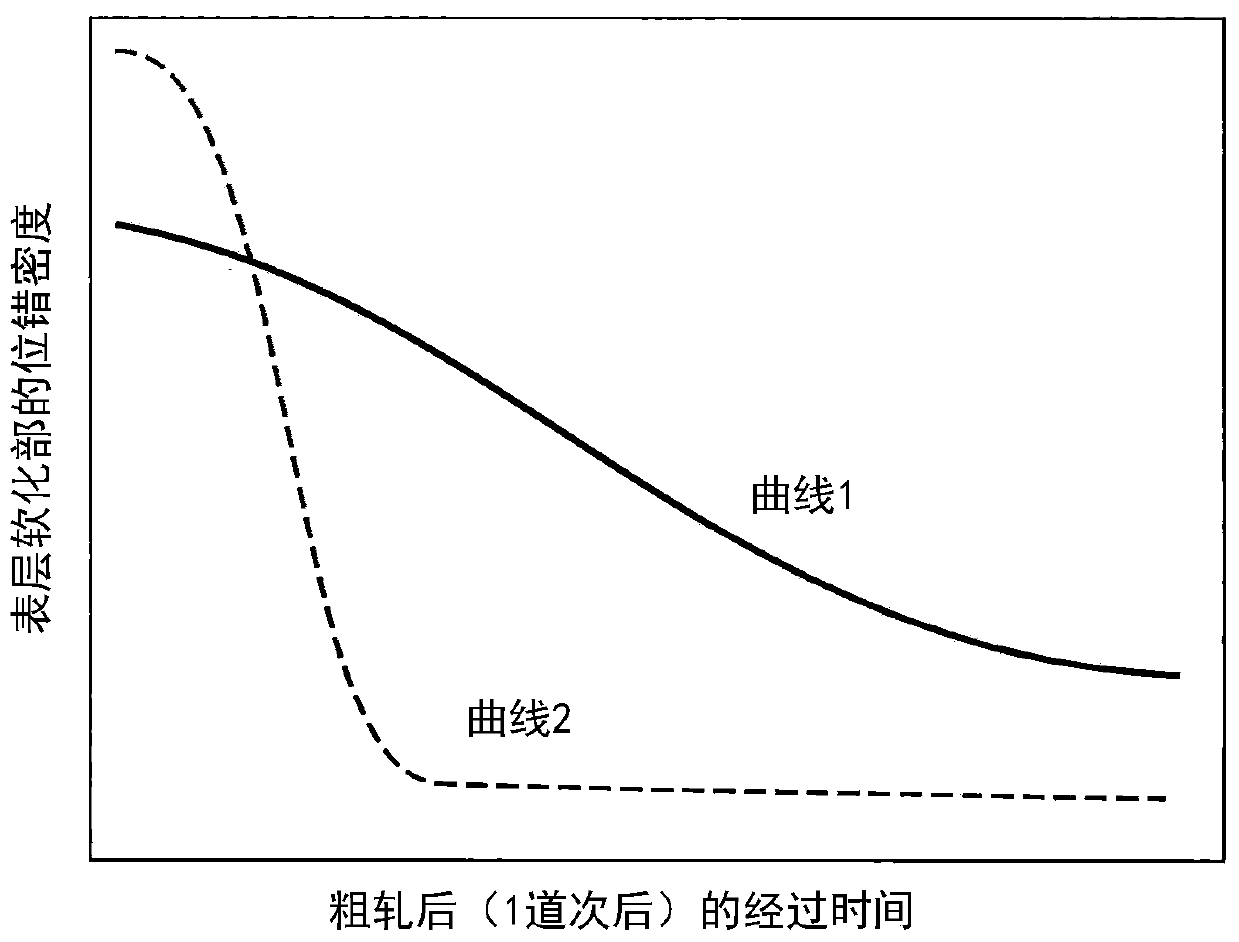

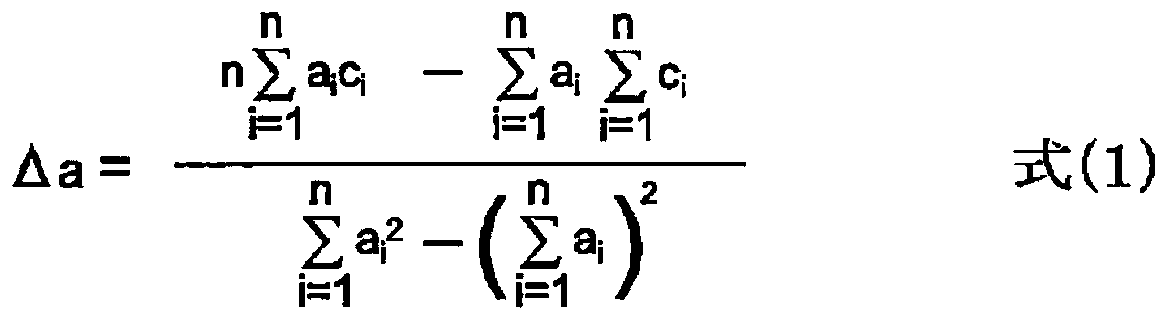

[0164] In this example, the hardness of the steel sheet after hot stamping was measured by the method described above, and the hardness at the central part of the sheet thickness and the change ΔH in hardness in the sheet thickness direction in the surface layer were calculated. 1 , The change in hardness in the thickness direction of the intermediate layer ΔH 2 .

[0165] In addition, a tensile test of the steel sheet after hot stamping was performed. For the tensile test, a No. 5 test piece described in JIS Z 2201 was produced, a...

Embodiment A

[0177]After the surface of the base steel sheet having the chemical composition shown in Table 1 was ground to remove surface oxides, surface layers having the chemical composition shown in Table 2 were laminated on both sides or one side by arc welding. Use a steel plate. In addition, the total thickness of the steel plate for the surface layer and the steel plate for the base material after arc welding is set to 200 mm to 300 mm, and the thickness of the steel plate for the surface layer is set to about 1 / 3 of the thickness of the steel plate for the base material (in the case of one side, 1 / 4 or so). Production Nos. 1 to 36 and 38 to 40 are steels with steel plates welded on both sides, and Production No. 37 is steel with steel plates welded to only one side. The laminated steel sheets were subjected to hot rolling and / or cold rolling as shown in Table 3, and the obtained steel sheets were subjected to the heat treatment shown in Table 3, followed by hot stamping to produc...

Embodiment B

[0195] [Example B (Mn: 1.50% or more and less than 3.00%)]

[0196] After grinding the surface of the base steel sheet having the chemical composition shown in Table 5 to remove surface oxides, the surface layers having the chemical composition shown in Table 6 were laminated on both sides or one side by arc welding. Use a steel plate. In addition, the total thickness of the steel plate for the surface layer and the steel plate for the base material after arc welding is set to 200 mm to 300 mm, and the thickness of the steel plate for the surface layer is set to about 1 / 3 of the thickness of the steel plate for the base material (in the case of one side, 1 / 4 or so). Production Nos. 101 to 135 and 137 to 139 are steels with steel plates welded on both sides, and Production No. 136 is steel with steel plates welded to only one side. The laminated steel sheets were subjected to hot rolling and / or cold rolling as shown in Table 7, and the obtained steel sheets were subjected to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com