Colored high-performance and anti-static radiation cross-linked polyethylene foam material and preparation method thereof

A technology for cross-linked polyethylene and foam materials, which is applied in the field of high-performance colored anti-static radiation cross-linked polyethylene foam materials and its preparation, can solve the problems of large static electricity and anti-static products, and easy precipitation of powder materials. Achieving good anti-static performance, good dazzling surface visual effects, and overcoming high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

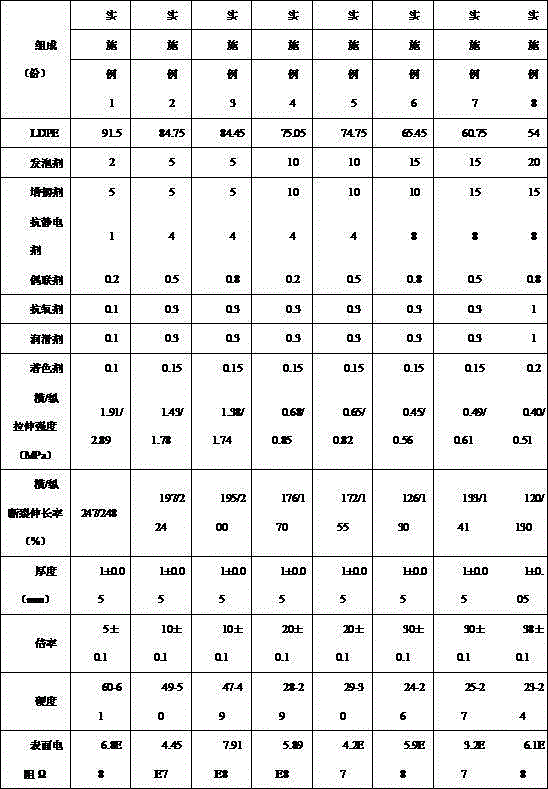

Examples

Embodiment 1

[0042] A preparation method of a high-performance colored antistatic radiation cross-linked polyethylene foam material, comprising the following steps: 91.5% of low-density polyethylene (LDPE), 2% of foaming agent, 5% of toughening agent, 1% antistatic agent, 0.2% coupling agent, 0.1% antioxidant, 0.1% lubricant, 0.1% coloring agent, mixed in a mixer at low speed for 240 seconds and then at high speed for 320 seconds, after a single melting temperature of 110-125 ° C The screw extruder extrudes into flakes, and the thickness of the flakes can be adjusted by the abrasive die and the pulling speed; the temperature of each section is: 105°C in the first zone, 110°C in the second zone, 120°C in the third zone, 110°C in the fourth zone, and 110°C in the fifth zone. Zone 110°C, zone six 120°C, die head 115°C, residence time of the mixture in the screw is 120 seconds. After being rolled into a sheet, it is then irradiated. The irradiation process conditions are: 2.1 Mev energy, 8 irr...

Embodiment 2

[0044] A preparation method of a high-performance color antistatic radiation cross-linked polyethylene foam material, comprising the following steps: 84.75% of low-density polyethylene (LDPE), 5% of foaming agent, 5% of toughening agent, 0.5% of coupling agent, 0.3% of antioxidant, 0.3% of lubricant, 0.15% of colorant, mixed in the mixer at low speed for 240 seconds and high speed for 320 seconds, and extruded through a single-screw extruder with a melting temperature of 110-125°C Formed into sheets, the thickness of the sheets can be adjusted through the mold die and traction speed; the temperature of each section is: 105 °C in the first area, 110 °C in the second area, 120 °C in the third area, 110 °C in the fourth area, 110 °C in the fifth area, and 110 °C in the sixth area 120°C, die head 115°C, residence time of the mixture in the screw is 120 seconds. After being rolled into a sheet, it is then irradiated. The irradiation process conditions are: 2.1 Mev energy, 8 irradia...

Embodiment 3

[0046] A preparation method of a high-performance colored antistatic radiation cross-linked polyethylene foam material, comprising the following steps: 84.45% low-density polyethylene (LDPE), 5% foaming agent, 5% toughening agent, 4% antistatic agent, 0.8% coupling agent, 0.3% antioxidant, 0.3% lubricant, 0.15% coloring agent, mixed in a mixer at low speed for 240 seconds and then at high speed for 320 seconds, after a single melting temperature of 110-125 ° C The screw extruder extrudes into flakes, and the thickness of the flakes can be adjusted by the abrasive die and the pulling speed. The rest of the preparation methods are the same as in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com