Polypropylene-based resin molded article and process for producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

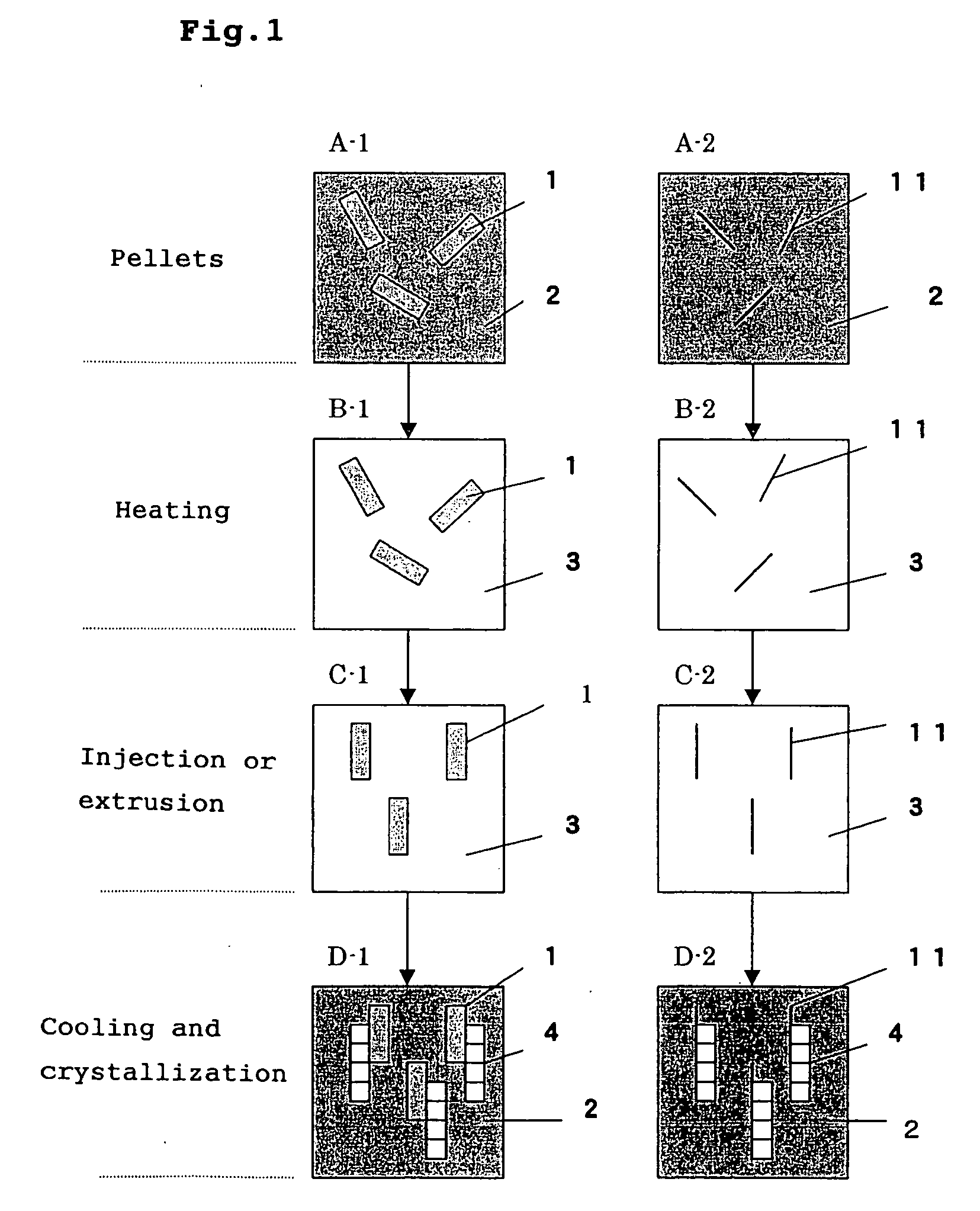

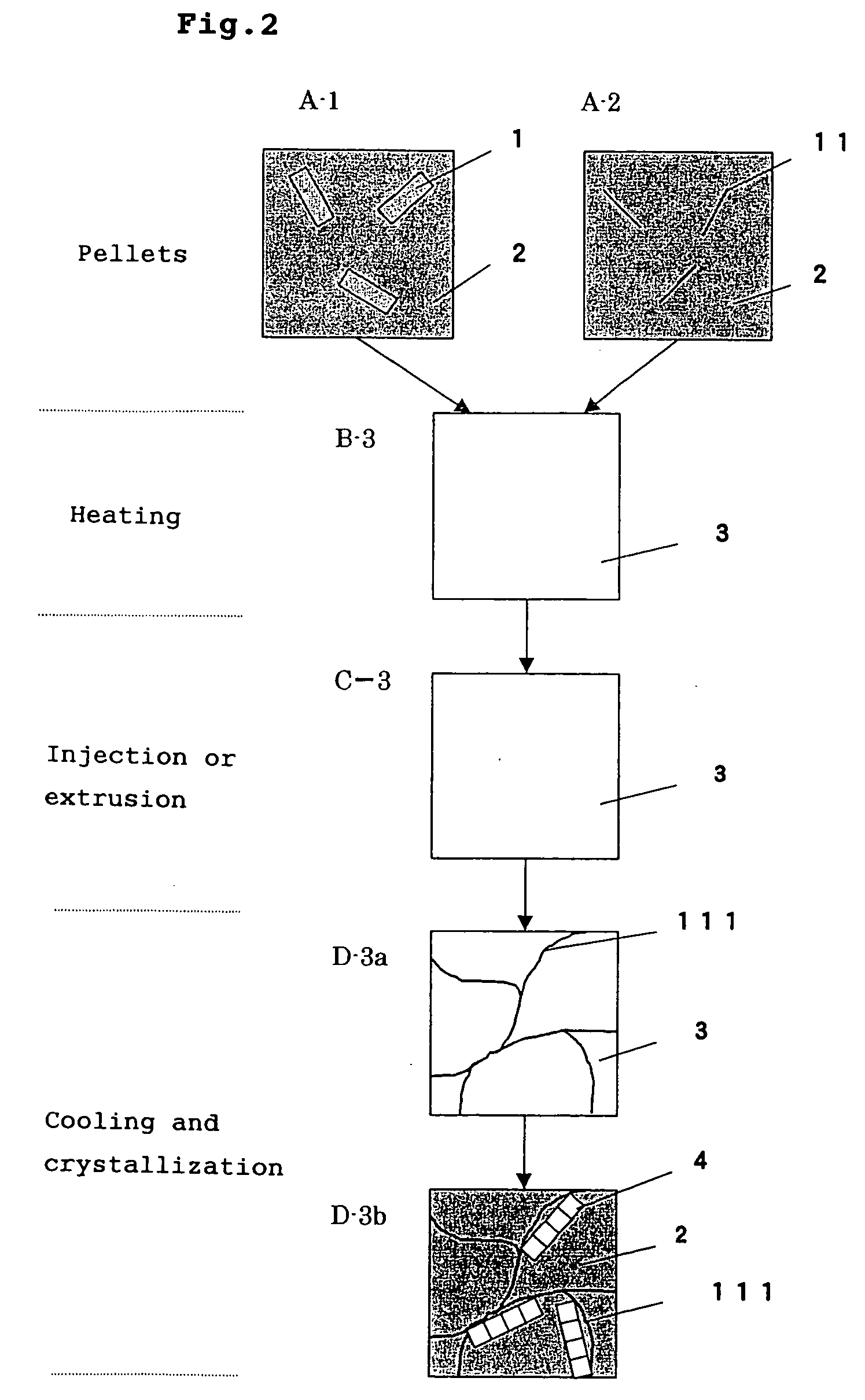

Method used

Image

Examples

example 1

[0093] N,N′-dicyclohexyl-2,6-naphthalenedicarboxamide as a β crystal nucleating agent (0.04 parts by weight), Irganox 1010 (tradename, product of Ciba Specialty Chemicals) as an oxidation stabilizer (0.05 parts by weight), and Irgafos 168 (tradename, product of Ciba Specialty Chemicals) (0.05 parts by weight) were mixed with a propylene homopolymer with a MFR of 2.0 g / 10 min (100 parts by weight), using a Henschel mixer. The resulting mixture was melted, kneaded and extruded at 250° C., and then cooled and cut to prepare β-nucleating agent-containing resin pellets.

[0094] The resin pellets were heated at 250° C. to dissolve the amide compound in the molten propylene homopolymer, and the melt was injection-molded at a mold temperature of 80° C. In this manner, several types of test pieces were obtained and tested for the above properties. Table 1 presents the results.

[0095] Complete dissolution of the amide compound in the molten polypropylene was confirmed by visually observing the...

example 2

[0096] Test pieces were prepared in the same manner as in Example 1 except that the β crystal nucleating agent was used in an amount of 0.05 parts by weight. The test pieces were tested for the properties. Table 1 presents the results.

example 3

[0097] Test pieces were prepared in the same manner as in Example 1 except that the β crystal nucleating agent was used in an amount of 0.06 parts by weight. The test pieces were tested for the properties. Table 1 presents the results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com