Multi-layer fireproof material for battery and manufacturing method of multi-layer fireproof material

A technology of fireproof material and production method, applied in the directions of lamination auxiliary operation, battery pack components, chemical instruments and methods, etc., can solve the problems of reducing battery heat dissipation efficiency, battery temperature rise, battery thermal runaway, etc., to reduce thermal runaway Probability, high impact resistance, the effect of thin and light products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

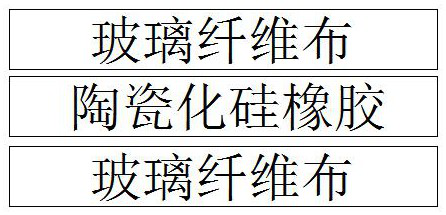

[0025] Such as figure 1 As shown, a multi-layer fireproof material for batteries includes a fireproof material body, the fireproof material body is composed of two layers of glass fiber cloth and a layer of ceramic silicon rubber, and the two layers of glass fiber cloth are respectively attached to the The upper surface and the lower surface of ceramicized silicone rubber, the thickness of the fireproof material body is 0.4-0.8mm, the tensile strength of the fireproof material body is greater than 20Mpa, and the hardness of the fireproof material body is 75HA-85HA. The density of the fireproof material body is 1.4g / cm³-1.8g / cm³.

[0026] When thermal runaway occurs, the glass fiber cloth can withstand the instantaneous strong impact caused by thermal runaway, while the ceramic silicone rubber will be quickly ceramicized in the high-temperature flame to block the impact of the high-temperature flame. The two-layer glass fiber cloth can completely absorb the impact of the explos...

Embodiment 2

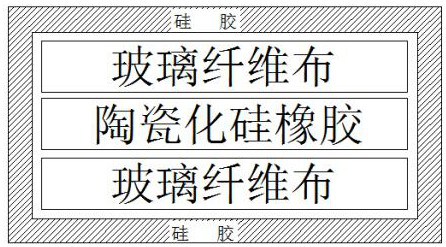

[0028] Such as figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 is that the outer surface of the fireproof material body is covered with silica gel, and the inner side of the coated silica gel can be in contact with the outer surface of the battery or battery cell. When the battery is in normal use, the silica gel can hold the battery or The heat from the outer surface of the battery cell is quickly transferred to the outer side of the silica gel, and the outer side of the silica gel is in contact with the air, thereby improving the heat dissipation efficiency of the battery.

Embodiment 3

[0030] A method for making a multi-layer fireproof material for batteries, comprising the following steps:

[0031] Step 1: Sandwich the vitrified silicone rubber between two layers of glass fiber cloth, heat and extrude the vitrified silicone rubber and glass fiber cloth through the upper and lower heating plates to make them stick together to form the body of the fireproof material. Adhesive bonding can be used.

[0032] Step 2: Apply the silica gel evenly on the outer surface of the fireproof material body, and the silica gel can be applied by spraying.

[0033] Step 3: Heating the silica gel coated on the surface of the fireproof material body, so that the silica gel adheres to the surface of the fireproof material body.

[0034] In step 1, the heating plate has two layers, and the fireproof material body is located between the two layers of heating plates, and the two layers of heating plates are gradually approached to squeeze the fireproof material.

[0035] The smear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com