Reinforced plastics spiral tubular product of composite steel strip

A technology for strengthening plastics and pipes, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of increased investment costs and manufacturing costs, complex prices of machinery and equipment, waste of plastic raw materials, etc. The effect of strong traceability and small adjustment workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

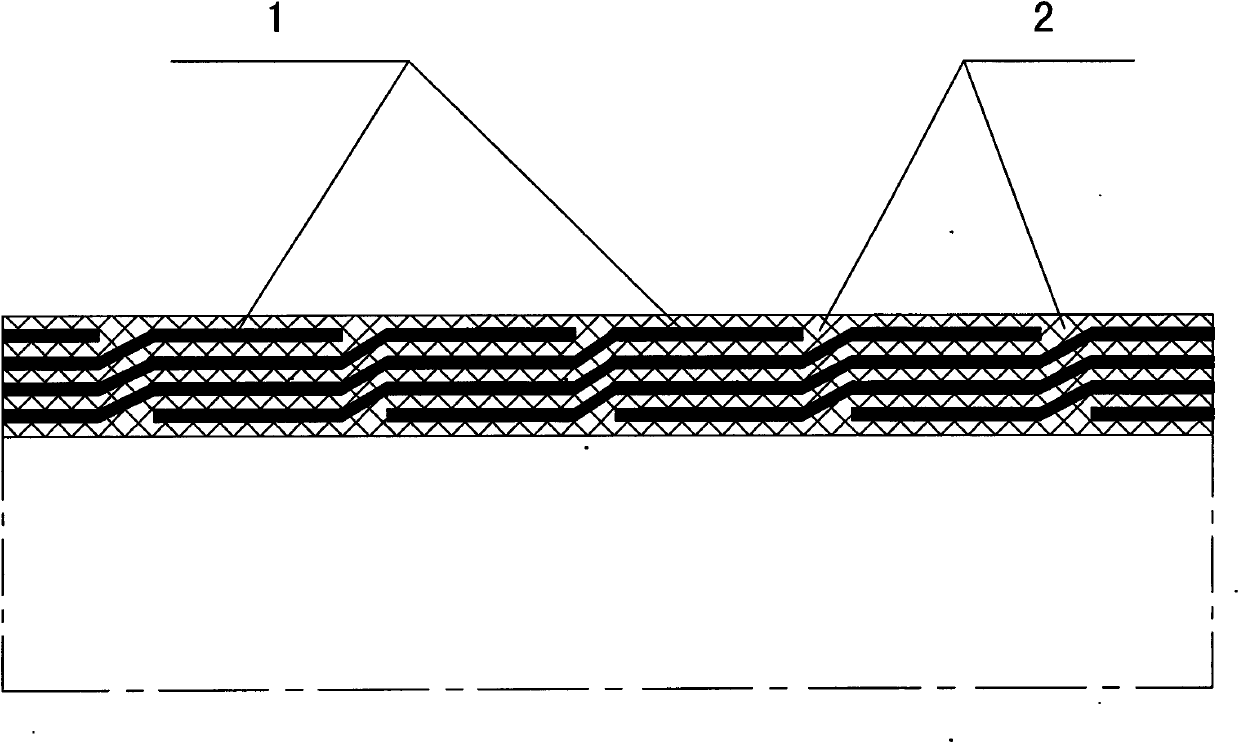

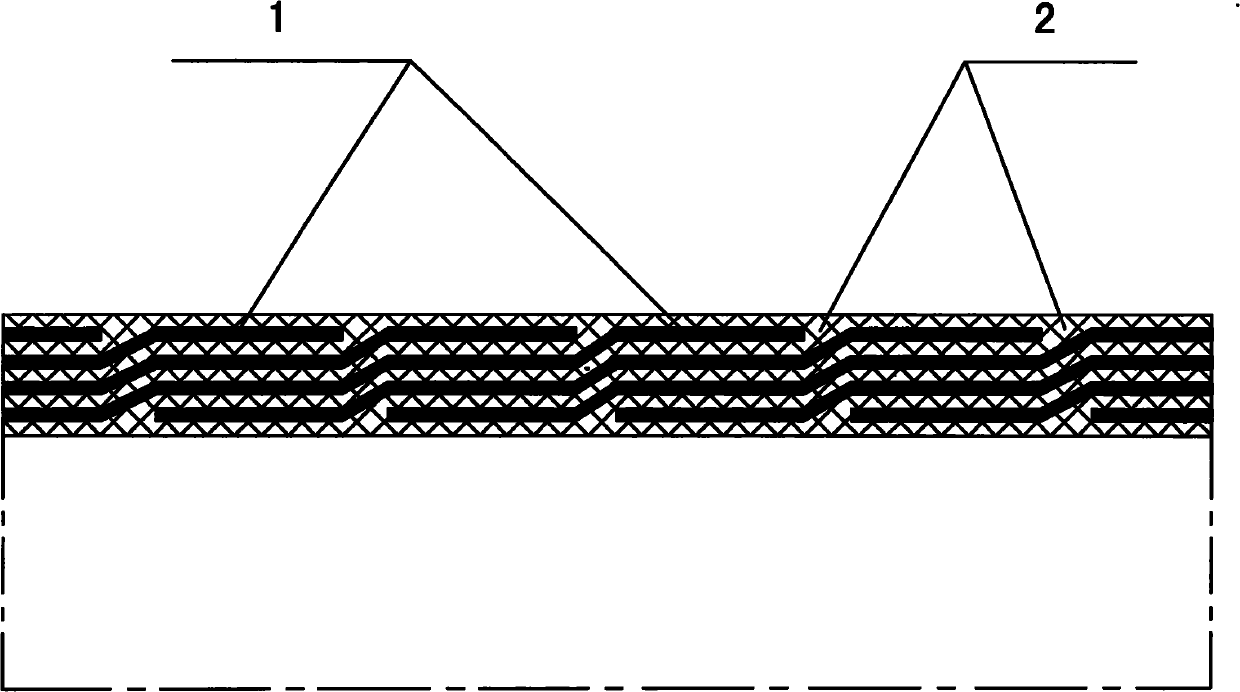

[0018] As shown in the accompanying drawings, the structure of the multi-layer steel belt reinforced plastic spiral pipe is supported by the steel skeleton 1, and the cold-rolled steel belt coated with adhesive resin after being degreased and derusted by polyethylene resin 2, Rolled by a cold-formed steel machine into a steel skeleton 1 in the shape of a "stair step", and then use a plastic extruder to bond the steel skeleton 1 and PVC 2 together to form a profile, and then use a spiral winding machine The equipment adopts the method of heating and melting plastics, and makes pipes after winding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com