Method for synthesizing and preparing hard alloy powder by mixing original powder and regenerated powder

A technology of cemented carbide and mixed powder, which is applied in the field of cemented carbide and powder metallurgy, can solve the problems of reducing the overall performance of bulk cemented carbide, the difficulty of uniform mixing of primary powder and recycled powder, and the unfavorable industrial application of recycled materials, etc., to achieve Excellent bending strength, easy to break, and eliminate the effect of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

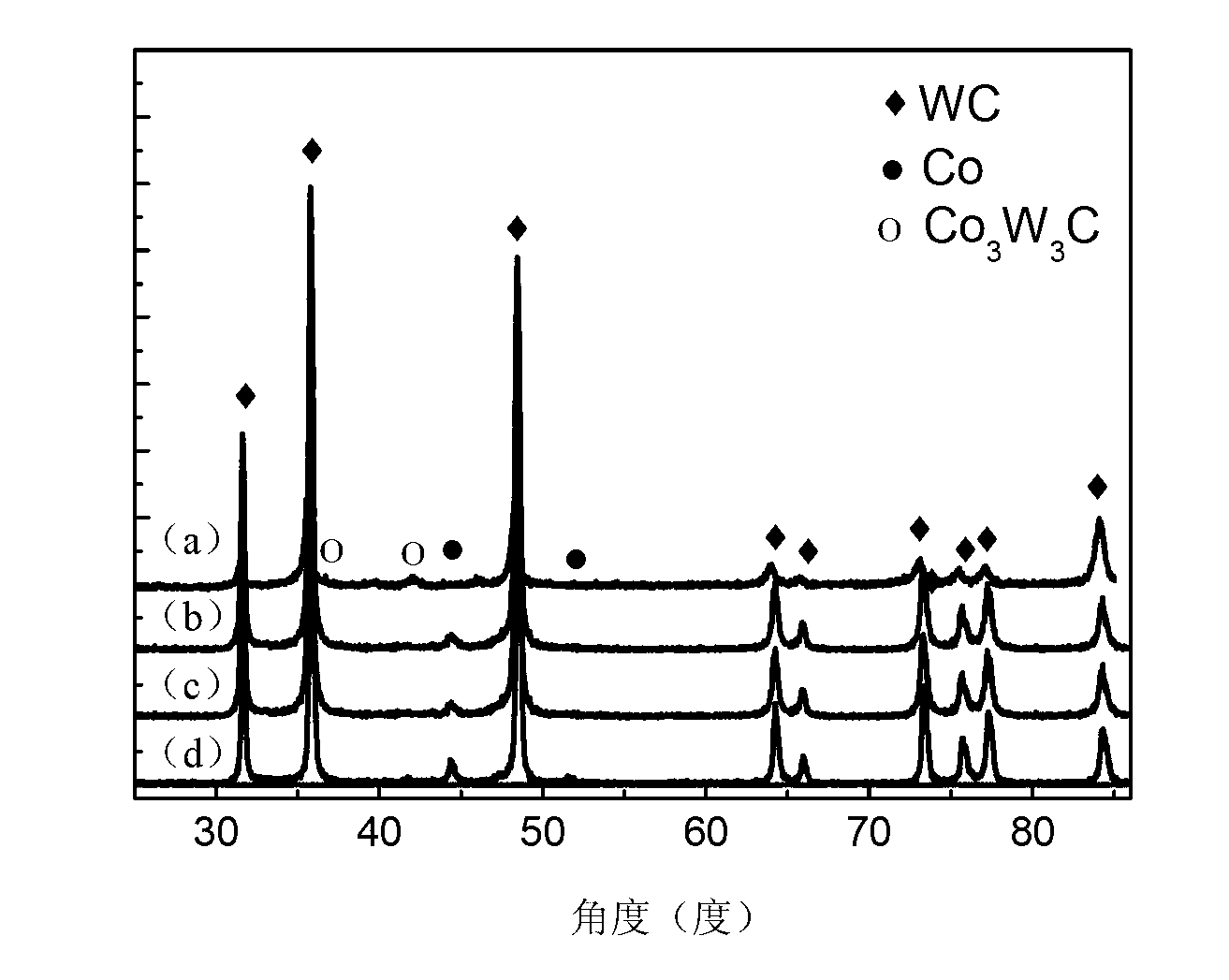

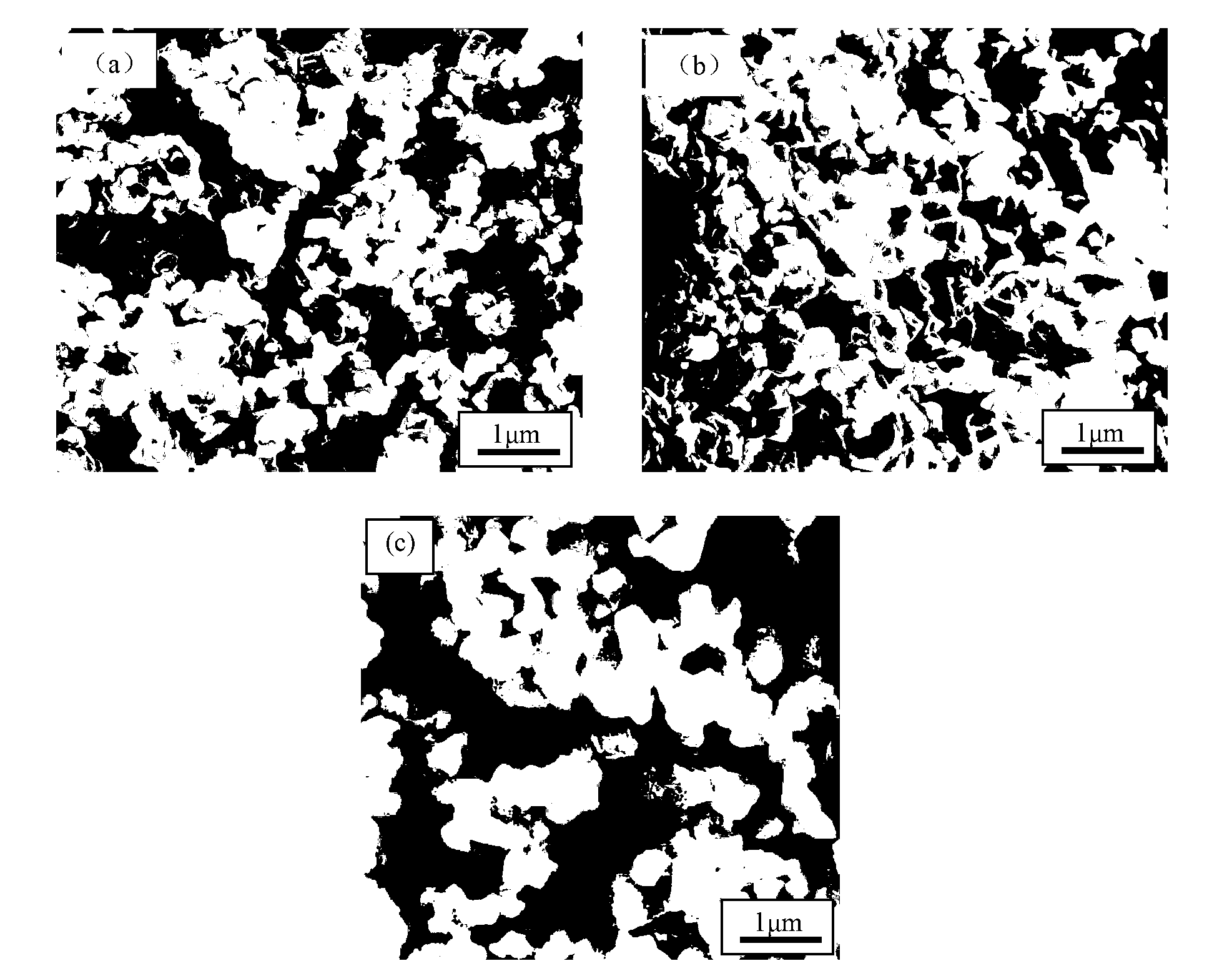

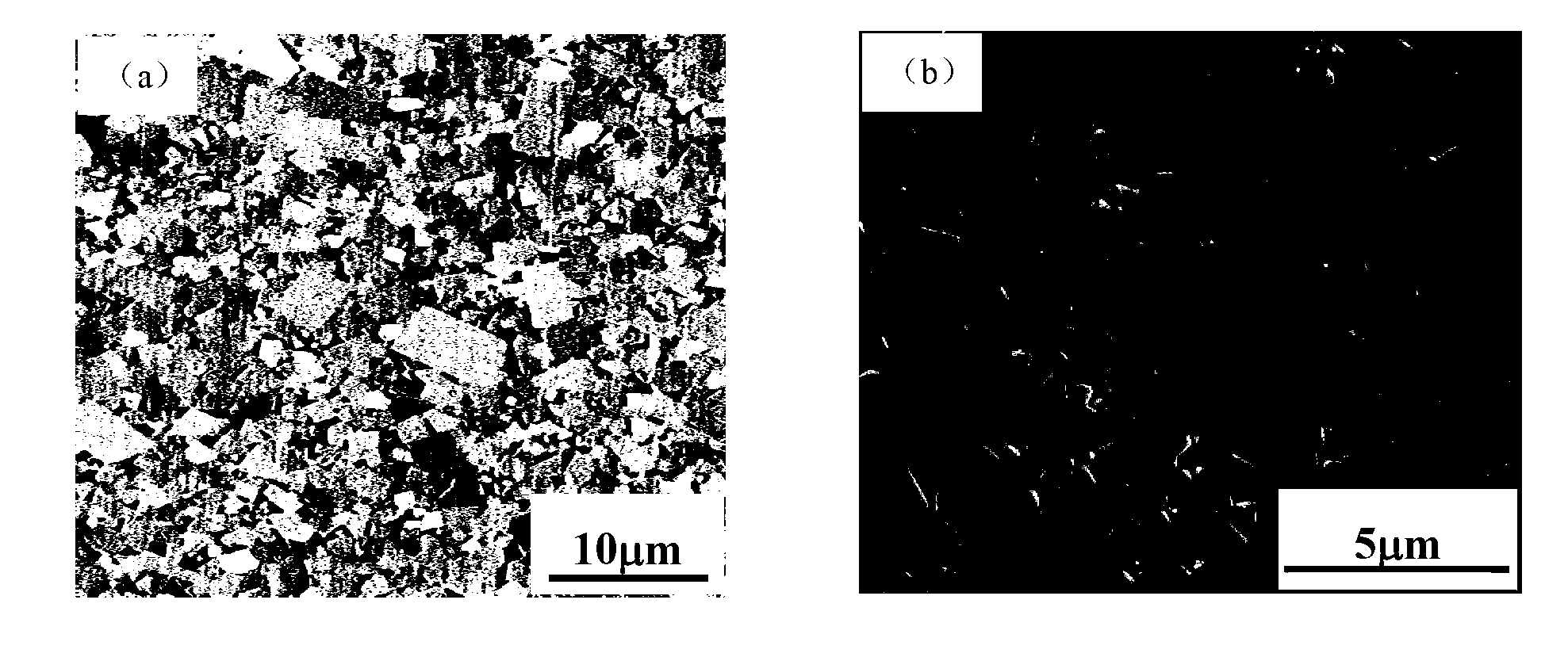

[0045] Example 1: The final product is WC-8wt.%Co (n=8) mixed powder with a recycled powder content of 10% (m=10) and the cemented carbide block material obtained by sintering this as a raw material. According to the requirements of the regenerated powder content and the Co content in the final WC-8wt.%Co mixed powder, according to the condition of n=p=8, according to the regenerated oxide mixture (WO 3 +CoWO 4 ), native WO 2.9 , native Co 3 o 4 The mass ratio of carbon black and carbon black is 1:8.1:0.8:2.0 for batching and ball milling; after ball milling, the powder is dried, and the final WC-Co mixed powder is prepared by reduction carbonization reaction in a vacuum furnace. The specific process parameters are: the gas pressure is less than 0.01Pa, the heating rate is 10°C / min, the reaction temperature is 1100°C, and the temperature is kept for 2 hours. The XRD pattern of the prepared final WC-Co mixed powder is shown in figure 1 (b), its scanning electron micrograph ...

example 2

[0048] Example 2: The final product is WC-6wt.%Co (n=6) mixed powder with a recycled powder content of m%=40%, and it is used as a raw material to sinter to obtain a cemented carbide block material. According to the requirements of the regenerated powder content and the Co content in the WC-6wt.%Co powder and the condition of n3 +CoWO 4 ), native WO 2.9 , native Co 2 o 3 The mass ratio of carbon black and carbon black is 1:2.3:0.14:0.50 for batching and ball milling; after ball milling, the powder is dried, and the final WC-6wt.%Co mixed powder is prepared by reduction carbonization reaction in a vacuum furnace. The specific process parameters are: the gas pressure is less than 0.01Pa, the heating rate is 20°C / min, the reaction temperature is 1080°C, and the heat preservation is 1.5 hours. The XRD pattern of the prepared final WC-Co mixed powder is shown in figure 1 (c), whose scanning electron micrograph is shown in figure 2 (b), 5 parts were randomly taken from the fina...

example 3

[0050] Example 3: The final product is WC-16wt.%Co (n=16) mixed powder with recycled powder content of 20% (m=20). According to the requirements of the regenerated powder content and the Co content in WC-16wt.%Co powder, according to the condition of n>p=8, according to the regenerated oxide mixture (WO 3 +CoWO 4 ), native WO 3 , native Co 3 o 4 The mass ratio of carbon black and carbon black is 1:3.4:0.8:0.9 for batching and ball milling; after ball milling, the powder is dried, and the reduction carbonization reaction is carried out in a vacuum furnace to prepare the final WC-16wt.%Co mixture containing 20% recycled powder pink. The specific process parameters are: the gas pressure in the furnace is less than 0.01Pa, the heating rate is 15°C / min, the reaction temperature is 1200°C, and the heat preservation is 3 hours. The XRD pattern of the prepared final WC-Co mixed powder is shown in figure 1 (d), its scanning electron micrograph is shown in figure 2 (c), 5 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com