Part vision detection device

A visual inspection device and technology for parts, applied in the field of industrial manufacturing, can solve the problems of inability to take into account the measurement of parts shape, inaccurate measurement results, and the influence of human factors, so as to avoid repeated calibration of the system, improve identification capabilities, and facilitate recording. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

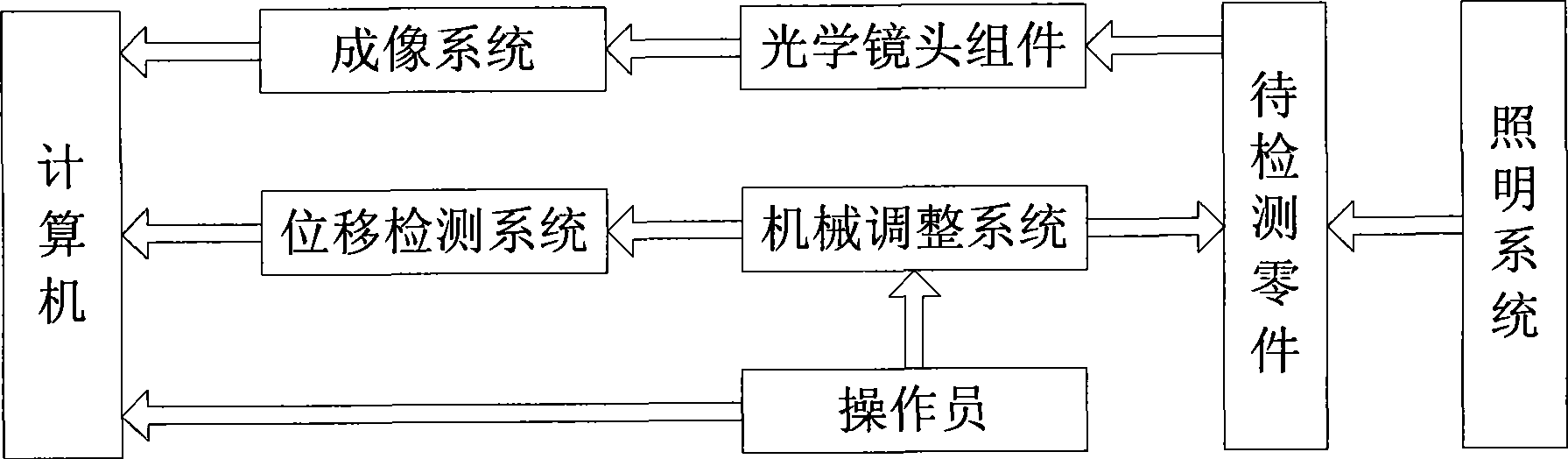

[0032] Such as figure 1 As shown, the present invention includes an imaging system composed of a CCD camera and an image acquisition card, an optical lens assembly composed of a lens body and a magnifying objective lens, an illumination system for shape measurement and surface defect detection, and a translation platform for adjusting the position of parts. The mechanical adjustment system, the displacement detection system to record the moving distance of the displacement platform, and the computer to record and process the image.

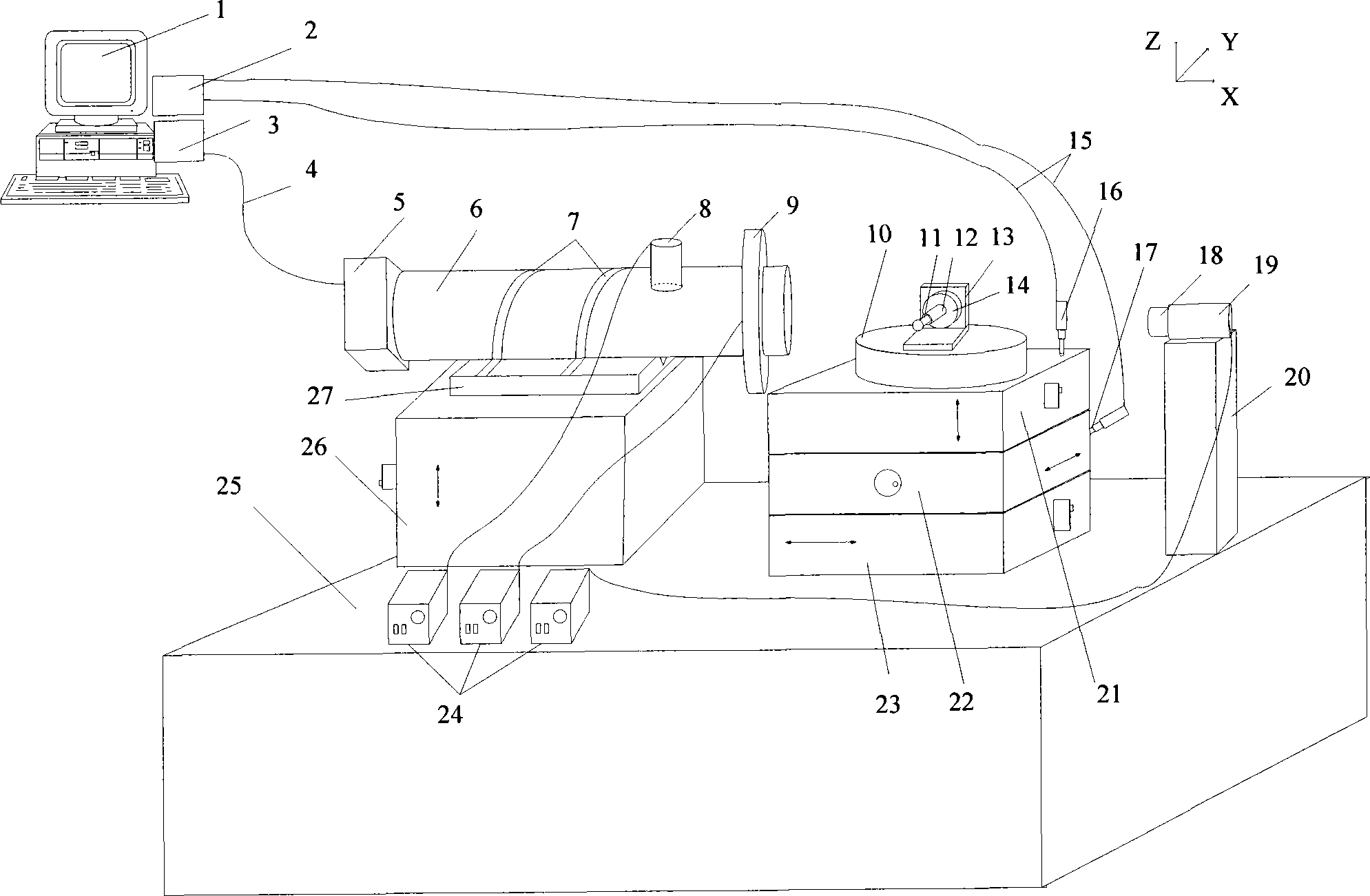

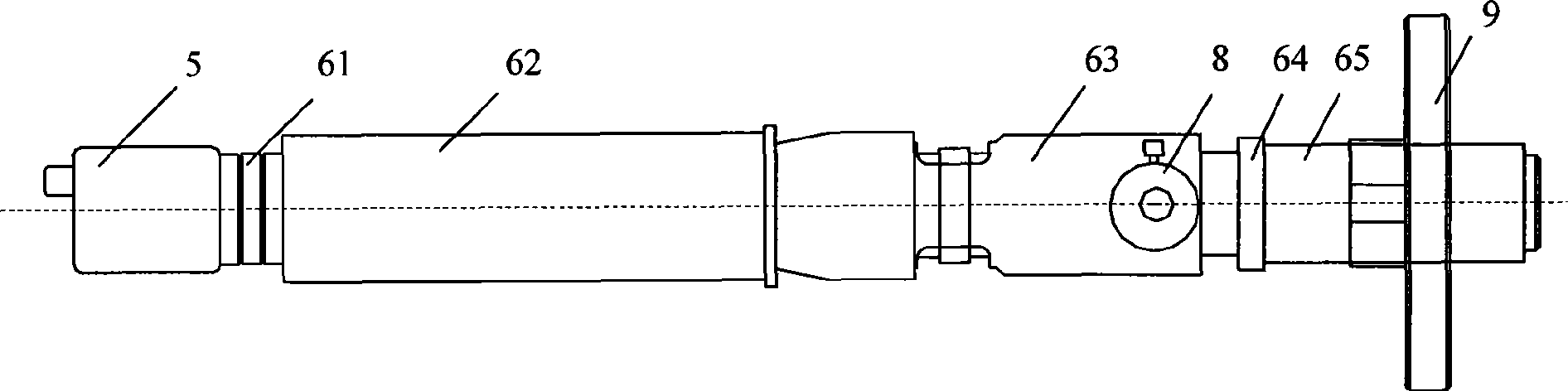

[0033] Such as figure 2 , 3 As shown, the lifting platform 26 is installed on the base 25, the V-shaped groove 27 is installed on the lifting platform 26, the optical lens assembly 6 is fixed on the V-shaped groove 27 by a steel belt 7, placed horizontally, the CCD camera 5 and the optical lens assembly 6 Conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com