High-temperature resistant and abrasion-resistant white cast iron piece and production method

A technology of white cast iron and production method, applied in the fields of high temperature resistant and wear resistant white cast iron castings and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

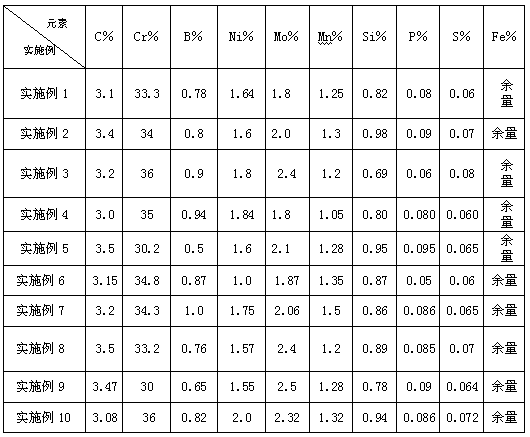

[0016] The high-temperature and wear-resistant white cast iron of the present invention adopts high-carbon and high-chromium chemical components, and adds boron, nickel, and molybdenum elements. The analysis of the role of the main elements in the steel is as follows:

[0017] 1. Chromium Cr: The mass fraction of Cr is 30-36% which is an important improvement in the present invention. Cr affects the number of carbides, and the increase of Gr content can improve the distribution of carbides. In high chromium cast iron, chromium can change the type of eutectic carbide, improve the shape of carbide, and improve the hardness and wear resistance of the material. With the increase of chromium content, the carbide type changes from M 3 C to M 7 C 3 to M 23 C 6 Transformation, in which the ratio of chromium to carbon, Cr / C, affects the M in cast iron 7 C 3 When the ratio is greater than 5, most of the M 7 C 3 type carbide. In addition to forming carbides with carbon, Cr is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com