Novel anti-aging compound rubber and preparation method thereof

A composite rubber and anti-aging technology, applied in the field of rubber, can solve the problems of short sealing strip size, unstable hardness, poor compression resistance, etc., to reduce plastic flow, reduce rough particles, improve aging resistance and corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] An anti-aging composite rubber sealing strip, the raw materials of which include by weight: 51 parts of ethylene propylene rubber, 69 parts of quick extruded carbon black, 1 part of zinc oxide by indirect method, 10 parts of anti-aging agent, 1 part of paraffin oil, and 10 parts of lubricant 1 part, 1 part vulcanizing agent, 8 parts accelerator.

[0019] Among them, the anti-aging agent is 2,2,4-trimethyl-1,2-dihydroquinoline polymer, the lubricant is zinc stearate, and the vulcanizing agent is 2,5-dimethyl-2,5-dihydroquinoline polymer. (tert-butylperoxy)hexane, the accelerator is a mixture of triallyl isocyanurate and trifunctional acrylate.

[0020] The preparation method of the anti-aging composite rubber sealing strip described in the present embodiment comprises the following steps:

[0021] S1. Preparation of synthetic rubber: mix the raw materials in proportion and send them into the internal mixer for internal mixing to obtain synthetic rubber 1, wherein the sy...

Embodiment 2

[0025] An anti-aging composite rubber sealing strip, its raw materials include by weight: 199 parts of ethylene-propylene rubber, 11 parts of quick-pressed carbon black, 15 parts of zinc oxide by indirect method, 1 part of anti-aging agent, 15 parts of paraffin oil, and 1 part of lubricant parts, 10 parts of vulcanizing agent, and 1 part of accelerator.

[0026] Among them, the anti-aging agent is 2,2,4-trimethyl-1,2-dihydroquinoline polymer, the lubricant is fatty acid salt, and the vulcanizing agent is 2,5-dimethyl-2,5-di( tert-butyl peroxy) hexane, and the accelerator is triallyl isocyanurate.

[0027] The preparation method of the anti-aging composite rubber sealing strip described in the present embodiment comprises the following steps:

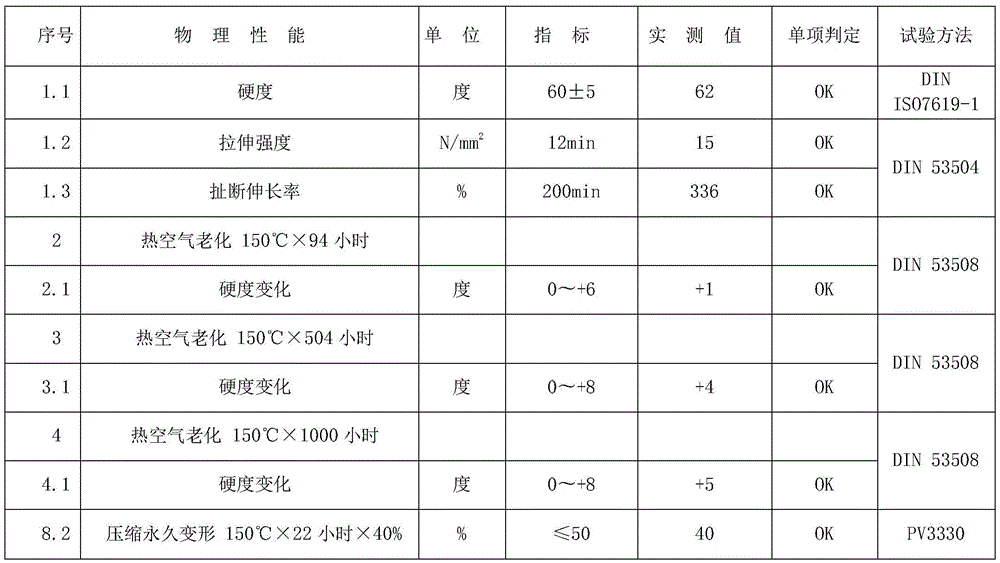

[0028] S1. Preparation of synthetic rubber: mix the raw materials in proportion and send them into the internal mixer for internal mixing to obtain synthetic rubber 1, wherein the synthetic rubber 1 has a hardness of 60±5 degrees, a str...

Embodiment 3

[0032] An anti-aging composite rubber sealing strip, the raw materials of which include by weight: 143 parts of ethylene-propylene rubber, 36 parts of quick-pressed carbon black, 9 parts of zinc oxide by indirect method, 6 parts of anti-aging agent, 8 parts of paraffin oil, and 7 parts of lubricant parts, 6 parts of vulcanizing agent, 5 parts of accelerator.

[0033] Among them, the anti-aging agent is 2-mercaptobenzimidazole zinc salt, the lubricant is zinc stearate, the vulcanizing agent is dicumyl peroxide, and the accelerator is trifunctional acrylate and trimethylolpropane trimethacrylate mixture.

[0034] The preparation method of the anti-aging composite rubber sealing strip described in the present embodiment comprises the following steps:

[0035] S1. Preparation of synthetic rubber: mix the raw materials in proportion and send them into the internal mixer for internal mixing to obtain synthetic rubber 1, wherein the synthetic rubber 1 has a hardness of 60±5 degrees,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com