Low-carbon cold-rolled precision ultrathin steel strip for toy industry, and process method and application thereof

A low-carbon steel and steel strip technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of easy falling off and difficult to color, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

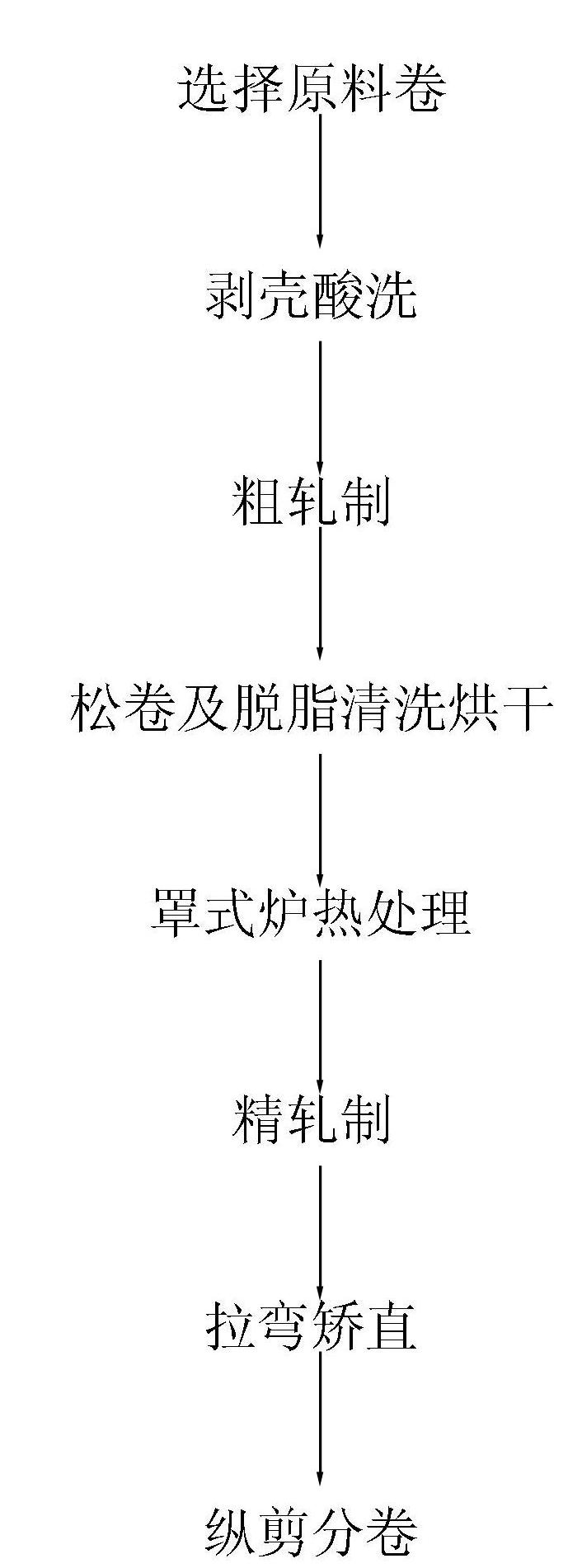

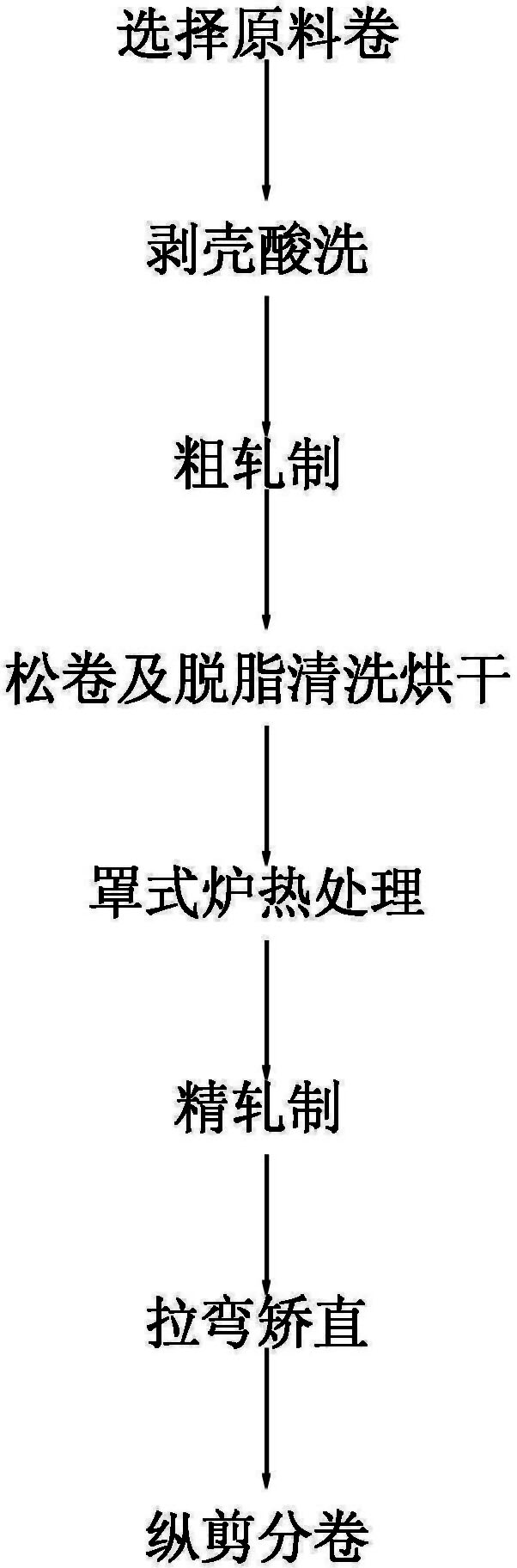

Method used

Image

Examples

Embodiment 1

[0069] In this embodiment, the selected brand is SPHC hot-rolled low-carbon steel raw material coil, which has a thickness of 3.0 mm and a width of 1245 mm. The thickness of the finished low carbon steel cold-rolled steel strip is 0.06mm±0.005, and the width is Vickers hardness HV≥170.

[0070] (1) Firstly, choose SPHC hot-rolled low-carbon steel raw material coil as raw material, its chemical composition: carbon (C) 0.04%, silicon (Si) 0.020%, manganese (Mn) 0.18%, phosphorus (P) 0.016%, Sulfur (S) 0.010%, its thickness is 3.0mm thick, width 455mm wide (1245mm wide slit).

[0071] (2) Peel and pickle the hot-rolled low-carbon steel raw material coils with a thickness of 3.0mm, clean, passivate and dry them. Three-trough shallow tank immersion pickling process is adopted, the pickling agent is hydrochloric acid, and it is divided into three tanks, and the concentration of the acid solution is 5%, 10%, 18%, and the pickling temperature is prepared according to the principle ...

Embodiment 2

[0085] In this embodiment, the selected grade is SPHC hot-rolled low-carbon steel raw material coil, which has a thickness of 2.75mm and a width of 1245mm. The finished low carbon steel cold rolled steel strip has a thickness of 0.06±0.005mm and a width of Vickers hardness HV≥170.

[0086] (1) Firstly, choose SPHC hot-rolled low-carbon steel raw material coil as raw material, its chemical composition: carbon (C) 0.04%, silicon (Si) 0.020%, manganese (Mn) 0.18%, phosphorus (P) 0.016%, Sulfur (S) 0.010%, its thickness is 2.75mm thick and 455mm wide (1245mm wide slit).

[0087] (2) The hot-rolled low-carbon steel raw material coils with a thickness of 2.75mm are peeled and pickled, cleaned, passivated and dried. Three-trough shallow tank immersion pickling process is adopted. The pickling agent is hydrochloric acid. It is divided into three tanks. The concentration of the acid solution is 12%, 15% and 18%, and the pickling temperature is in order. It is 75°C, 78°C, and 80°C. ...

Embodiment 3

[0101] In this embodiment, the selected brand is SPHC hot-rolled low-carbon steel raw material coil, which has a thickness of 1.0 mm and a width of 1245 mm. The finished low carbon steel cold rolled steel strip has a thickness of 0.03±0.005mm and a width of Vickers hardness HV≥170.

[0102] (1) Firstly, choose SPHC hot-rolled low-carbon steel raw material coil as raw material, its chemical composition: carbon (C) 0.04%, silicon (Si) 0.020%, manganese (Mn) 0.18%, phosphorus (P) 0.016%, Sulfur (S) 0.010%, its thickness is 1.0mm thick, width 455mm wide (1245mm wide slit).

[0103] (2) The hot-rolled low-carbon steel raw material coils with a thickness of 1.0mm are peeled and pickled, cleaned, passivated and dried. The two-trough shallow tank immersion pickling process is adopted. The pickling agent is hydrochloric acid. It is divided into two tanks. The concentration of the acid solution is 15%, 20% and the pickling temperature is 40°C in order to increase according to the run...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com