Anti-counterfeiting cloth paper and preparation method thereof

A technology of cloth paper and paper sheets, which is applied in the field of anti-counterfeit paper preparation, can solve the problems of increased equipment and production costs, large changes, and expensive costs, and achieve the effects of enhanced physical strength, improved folding resistance, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

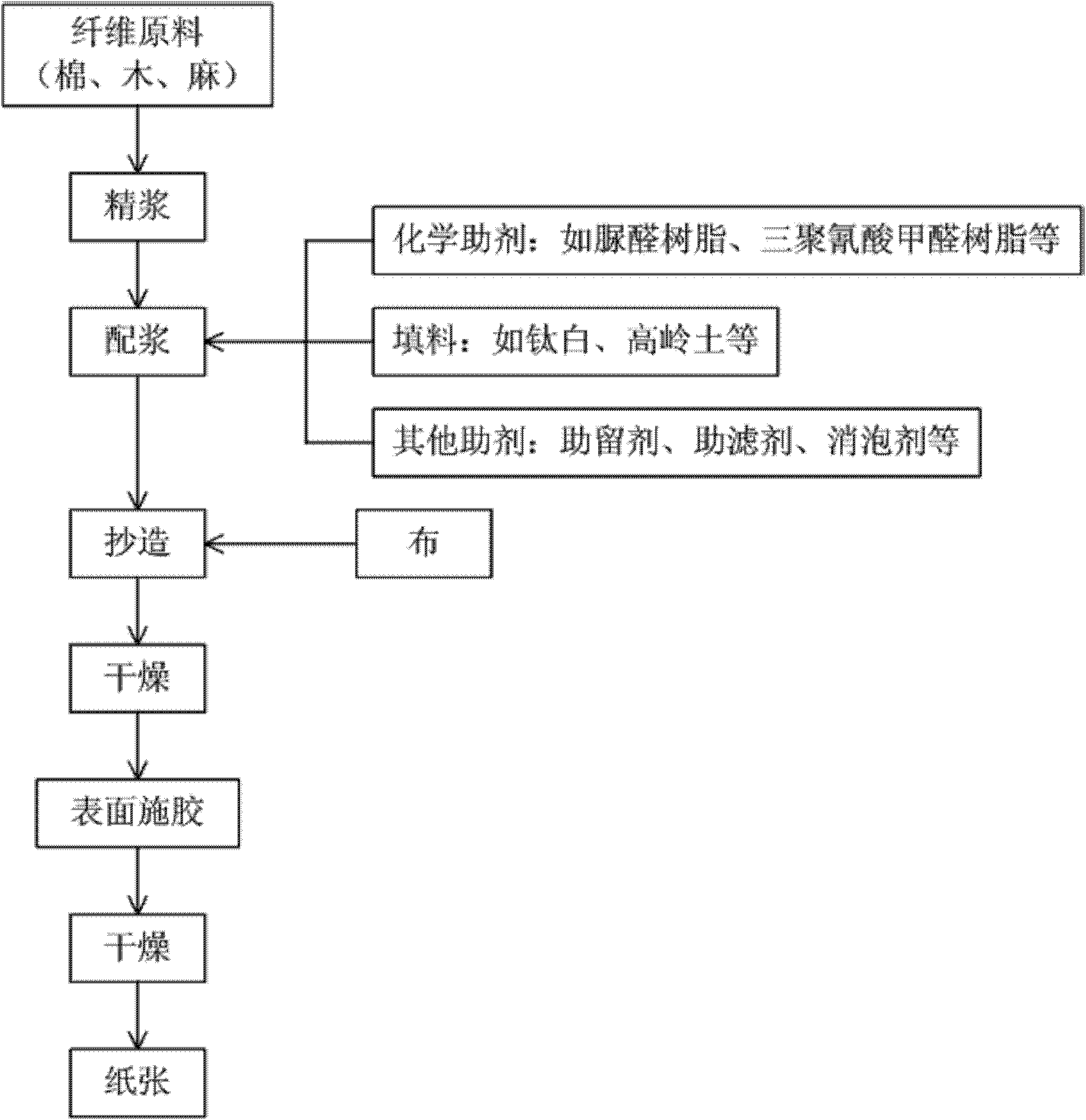

[0044] The flow process of the preparation method of the anti-counterfeiting cloth paper provided by the present invention is as follows: figure 2 As shown, it can be carried out according to the following specific steps:

[0045] To prepare a cloth containing anti-counterfeiting material (which can be called anti-counterfeiting cloth), the following methods can be used:

[0046] 1. Anti-counterfeiting materials are added by printing: use a loom to weave fabrics through ordinary plain weaving; add anti-counterfeiting materials (such as fluorescent materials, temperature-changing materials, magnetic materials, etc.) to ink, and transfer them through a screen printing machine Put it on the above cloth to get the anti-counterfeit cloth, or add the above-mentioned anti-counterfeit material into the ink and transfer it to the above-mentioned cloth through a digital printing machine to get the anti-counterfeit cloth.

[0047] 2. Anti-counterfeiting materials are added in the form ...

Embodiment 1

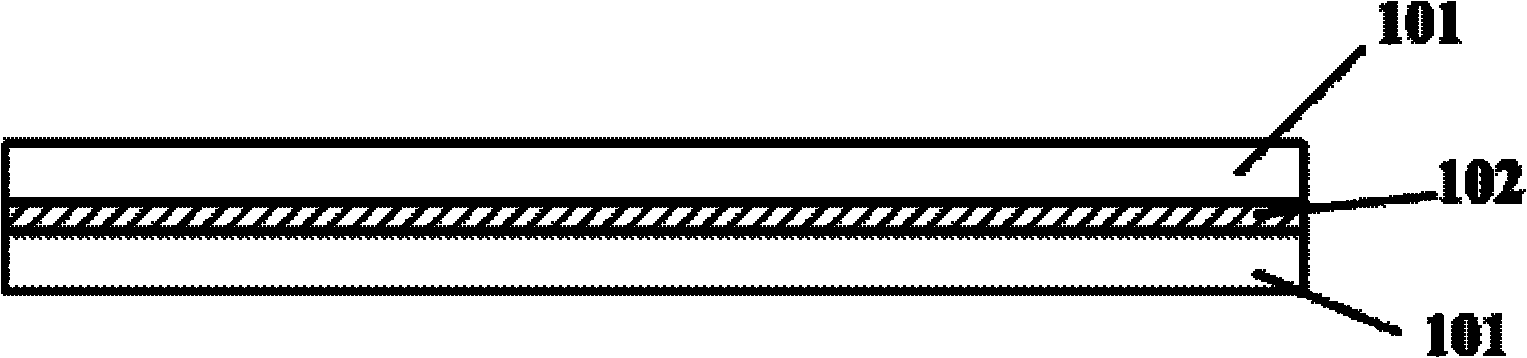

[0082] This embodiment provides a kind of anti-counterfeiting cloth paper, which has a sandwich structure formed by one layer of cloth 102 (thickness is 100 μm) and two layers of paper 101, such as figure 1 Shown, wherein, above-mentioned cloth contains thermosensitive material.

[0083] The anti-counterfeiting cloth paper is prepared through the following steps:

[0084] (1) Weaving: use viscose silk to weave into cloth, wherein the yarn interweaving density is: warp density 30 threads / cm, weft density 30 threads / cm;

[0085] (2) Composite cloth and anti-counterfeiting material: Add 2% (by ink weight) of inorganic thermochromic substance (when heated, the substance can change from colorless to green, and the discoloration temperature is 60°C) to ordinary ink to obtain heat-sensitive ink, The maple leaf pattern is printed on the cloth by thermal transfer, the maple leaves are evenly distributed on the cloth, the distance between the maple leaves is controlled to 10mm, and the...

Embodiment 2

[0092] This embodiment provides a kind of anti-counterfeit cloth paper, which has a sandwich structure formed by one layer of polyamide filament cloth and two layers of paper, wherein the polyamide filament cloth contains blue ultraviolet fluorescent powder, which is colorless to 50°C. Red temperature-changing powder.

[0093] The anti-counterfeiting cloth paper is prepared through the following steps:

[0094] (1) Combining fibers with anti-counterfeiting materials: In the spinning process of polyamide filaments, blue ultraviolet fluorescent powder and 50°C colorless to red temperature-changing powder are added to the spinning stock solution (addition amount can be adjusted) Controlled to 0.5-9.5% of the quality of the spinning stock solution), a polyamide anti-counterfeit filament with both fluorescent effect and temperature-changing effect is obtained by melt spinning, and the fiber fineness is 50D;

[0095] (2) Weaving: Use polyamide filament anti-counterfeiting fiber as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com