Rare earth concrete water reducing agent for building

A concrete water reducing agent and construction technology, applied in the field of water reducing agent, can solve the problems of poor use effect of water reducing agent, achieve the effect of improving corrosion resistance, improving impermeability, and ensuring the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

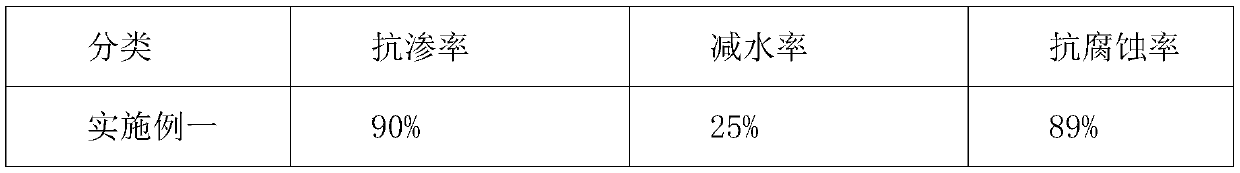

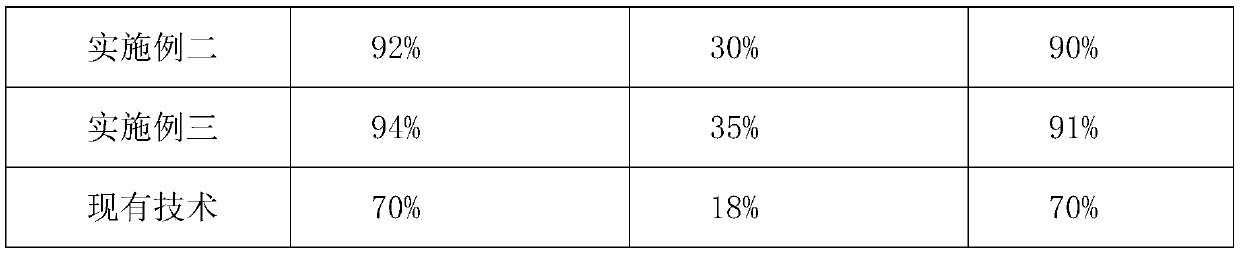

Examples

Embodiment 1

[0029] A rare earth concrete water reducing agent for construction, comprising the following raw materials in parts by weight: 5-9 parts of naphthalene, 3 parts of concentrated sulfuric acid, 2 parts of formaldehyde, 1 part of melamine, 7 parts of phenol, 4 parts of sodium sulfamate, 6 parts of liquid caustic soda, 20 parts of water.

[0030] Its preparation method comprises the following steps:

[0031] S1, put naphthalene into the naphthalene kettle with a capacity of 400ml and heat and melt for 0.5h, put into concentrated sulfuric acid after melting to obtain naphthalenesulfonic acid a and naphthalenesulfonic acid b;

[0032] S2, adding water to naphthalenesulfonic acid a for hydrolysis for 1h, after hydrolysis, putting formaldehyde, melamine and naphthalenesulfonic acid b into a reaction kettle with a capacity of 800ml for reaction for 2h to obtain activator A;

[0033] S3, add phenol and sodium sulfamate in the reaction kettle, react with activator A for 1h, continuously...

Embodiment 2

[0037] A rare earth concrete water reducing agent for construction, comprising the following raw materials in parts by weight: 5-9 parts of naphthalene, 4 parts of concentrated sulfuric acid, 3 parts of formaldehyde, 2 parts of melamine, 8 parts of phenol, and 5 parts of sodium sulfamate, 7 parts of liquid caustic soda, 25 parts of water.

[0038] Its preparation method comprises the following steps:

[0039] S1, put 7 parts of naphthalene into the naphthalene still with a capacity of 500ml and heat and melt for 0.6h, put into 4 parts of concentrated sulfuric acid after melting to obtain naphthalenesulfonic acid a and naphthalenesulfonic acid b;

[0040] S2, adding water to naphthalenesulfonic acid a for hydrolysis for 2h, after hydrolysis, putting formaldehyde, melamine and naphthalenesulfonic acid b into a reaction kettle with a capacity of 900ml to react for 3h to obtain activator A;

[0041] S3, add phenol and sodium sulfamate in the reaction kettle, react with activator ...

Embodiment 3

[0045] A rare earth concrete water reducing agent for construction, comprising the following raw materials in parts by weight: 5-9 parts of naphthalene, 5 parts of concentrated sulfuric acid, 4 parts of formaldehyde, 3 parts of melamine, 9 parts of phenol, 6 parts of sodium sulfamate, 8 parts of liquid caustic soda, 30 parts of water.

[0046] Its preparation method comprises the following steps:

[0047] S1, put naphthalene into the naphthalene kettle with a capacity of 600ml and heat and melt for 0.7h, put into concentrated sulfuric acid after melting to obtain naphthalenesulfonic acid a and naphthalenesulfonic acid b;

[0048] S2, adding water to naphthalenesulfonic acid a for hydrolysis for 3h, after hydrolysis, putting formaldehyde, melamine and naphthalenesulfonic acid b into a reaction kettle with a capacity of 1000ml to react for 4h to obtain activator A;

[0049] S3, add phenol and sodium sulfamate in the reaction kettle, react with activator A for 3h, continuously a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com