Laser method for removing paint on autobody

A car body and paint technology, which is applied in the laser field of removing car body paint, can solve the problems that the polishing effect cannot be guaranteed, needs to be cleaned, and labor costs increase, so as to achieve the effect of avoiding waste of water resources and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

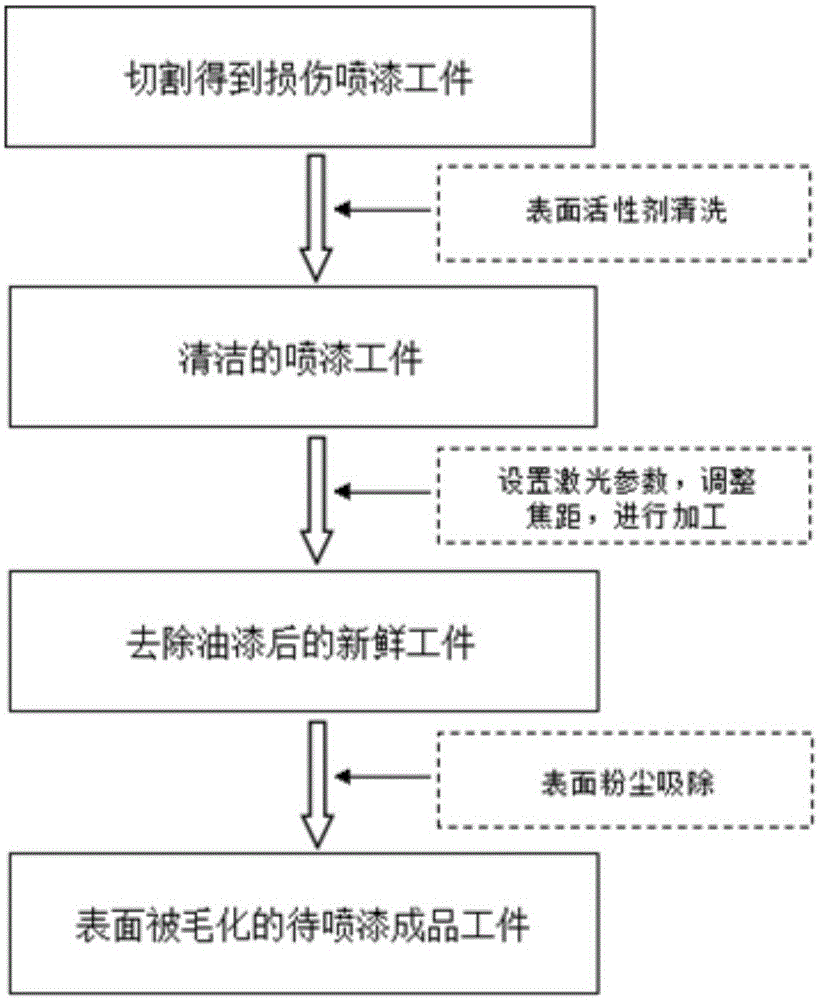

[0040] (1) Cut and damage the painted workpiece;

[0041] (2) Take the workpiece to be repaired, place it in a pre-prepared surface active solution, use ultrasonic vibration, wash it with deionized water, and air dry it.

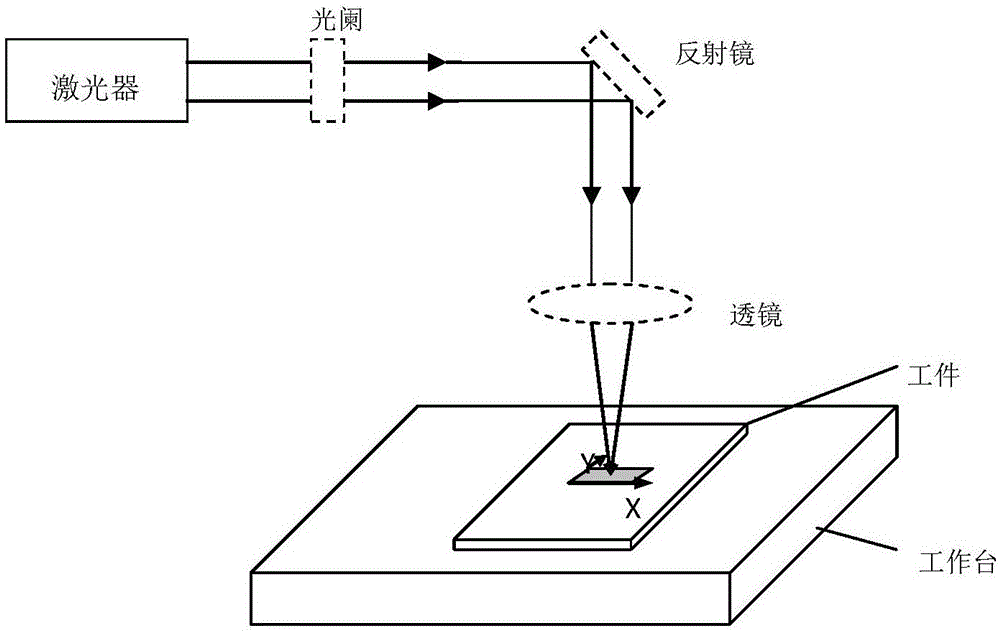

[0042] (3) Place the sample on the worktable of Edgewave's PX series nanosecond laser processing system (using green light configuration with a wavelength of 532nm), set the laser power to 20W, the frequency to 10KHz, the current to 60A, and the scanning speed to 1000mm / s , the number of repetitions is n=10 times, the size of the scanning area is set to 5mm×5mm, and the laser system is started to start processing.

[0043] (4) Use a small suction device to remove particulate matter on the surface of the workpiece, remove the processed workpiece, and the surface of the workpiece will be roughened.

Embodiment 2

[0045] (1) Cut and damage the painted workpiece;

[0046] (2) Take the workpiece to be repaired, place it in a pre-prepared surface active solution, use ultrasonic vibration, wash it with deionized water, and air dry it.

[0047] (3) Place the sample on the worktable of Edgewave's PX series nanosecond laser processing system (using a green light configuration with a wavelength of 532nm), set the laser power to 20W, the frequency to 10KHz, the current to 60A, and the scanning speed to 500mm / s , the number of repetitions is n=10 times, the size of the scanning area is set to 5mm×5mm, and the laser system is started to start processing.

[0048] (4) Use a small suction device to remove particulate matter on the surface of the workpiece, remove the processed workpiece, and the surface of the workpiece will be roughened.

Embodiment 3

[0050] (1) Cut and damage the painted workpiece;

[0051] (2) Take the workpiece to be repaired, place it in a pre-prepared surface active solution, use ultrasonic vibration, wash it with deionized water, and air dry it.

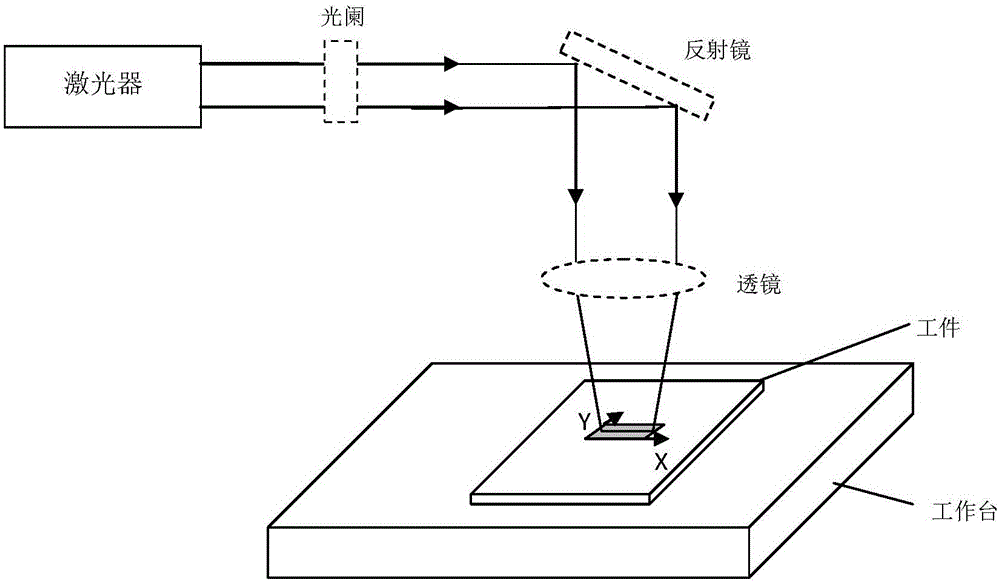

[0052] (3) Place the sample on the worktable of Edgewave's PX series nanosecond laser processing system (using green light configuration with a wavelength of 532nm), set the laser power to 20W, the frequency to 10KHz, the current to 60A, and the scanning speed to 1000mm / s , the number of repetitions is n=10 times, adjust the galvanometer to make the laser output a line light source, set the scanning area size to 5mm×5mm, start the laser system to start processing.

[0053] (4) Use a small suction device to remove particulate matter on the surface of the workpiece, remove the processed workpiece, and the surface of the workpiece will be roughened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com