Optical lens polishing device and polishing process

A technology for optical lenses and polishing devices, which is applied to optical surface grinders, grinding/polishing equipment, manufacturing tools, etc., and can solve problems such as difficulty in ensuring lens surface shape and polishing accuracy, lens deformation, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

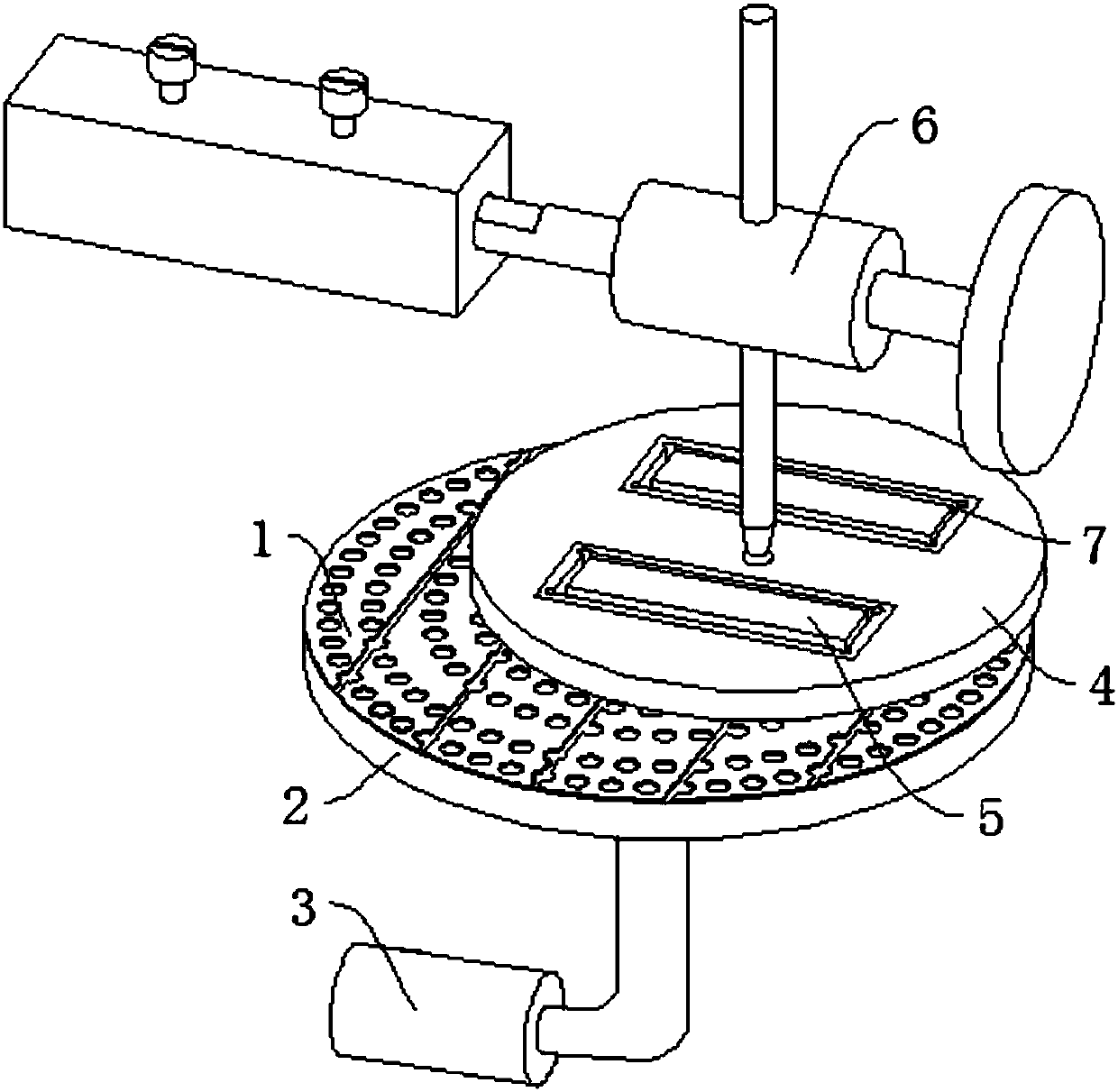

[0031] Referring to the accompanying drawings, in one embodiment of the present invention: an optical lens polishing device includes: a polishing pad 1 , a polishing pad base 2 , a rotary drive device 3 , a separator 4 , a pressing block 5 and a polishing machine 6 . The polishing pad 1 is made of polyurethane, bonded to the polishing pad base 2 by a thermosetting adhesive such as epoxy resin or organic silicon, and the polishing pad base 2 moves under the drive of the rotary drive device 3, which can be an ordinary motor. The separator 4 is placed on the polishing pad 1, the separator 4 is provided with a plurality of loading tanks 7, the loading tanks 7 can be in any shape such as square or circular, and the inner wall of the loading tank 7 is provided with a protective cover; The block 5 is movably placed in the loading tank of the separator 4, and is applied to the lens by the gravity of the pressing block 5 itself; The polishing pad base 2 and the polishing machine 6 form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com