Nano-microcapsule coated intravascular stent of core-shell structure and preparation method of intravascular stent

A core-shell structure and vascular stent technology, applied in the field of medical devices, can solve the problem of high thrombosis rate, and achieve the effects of high preparation efficiency, cell adhesion, and repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

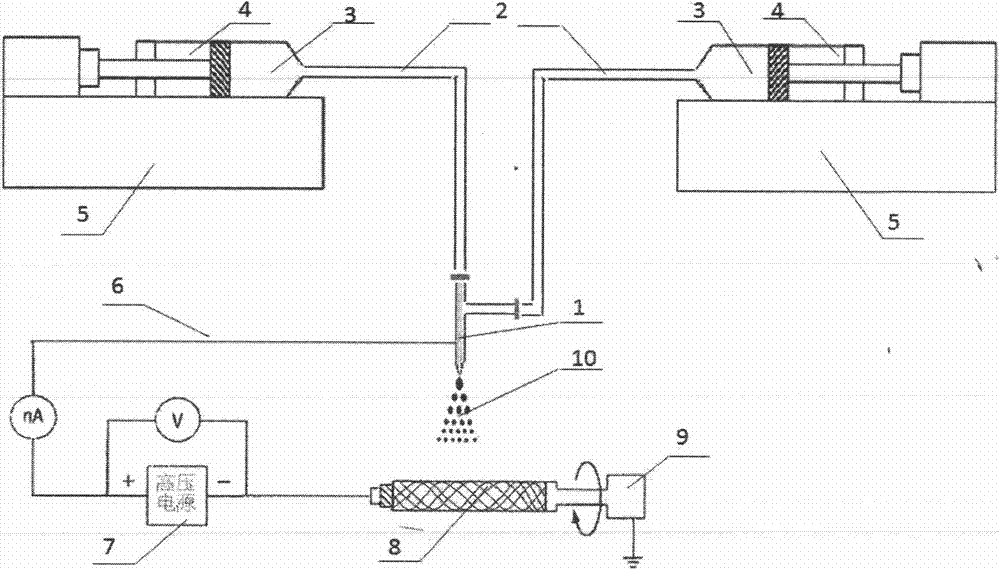

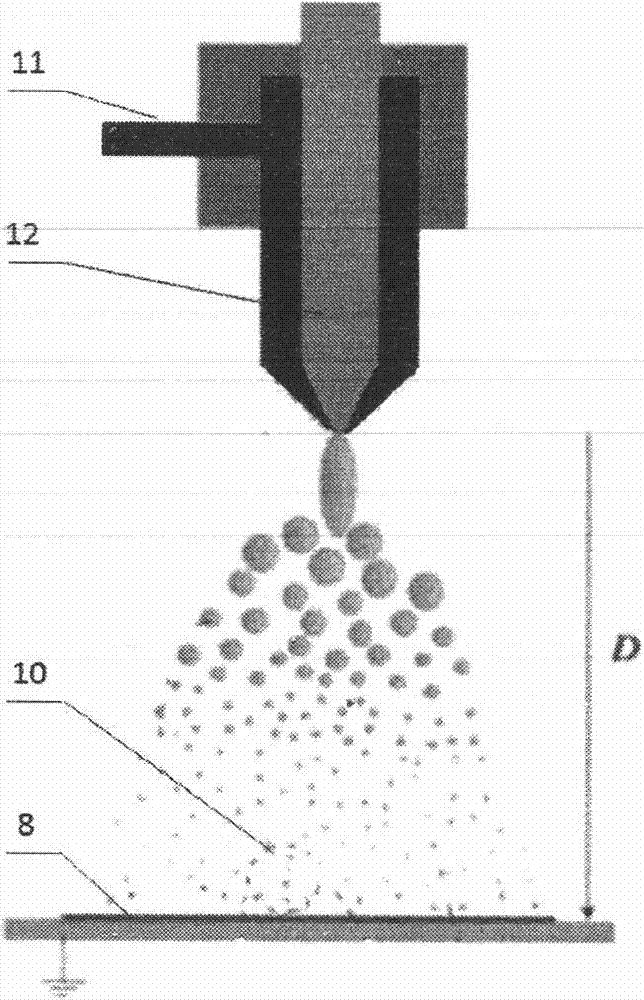

Method used

Image

Examples

Embodiment 1

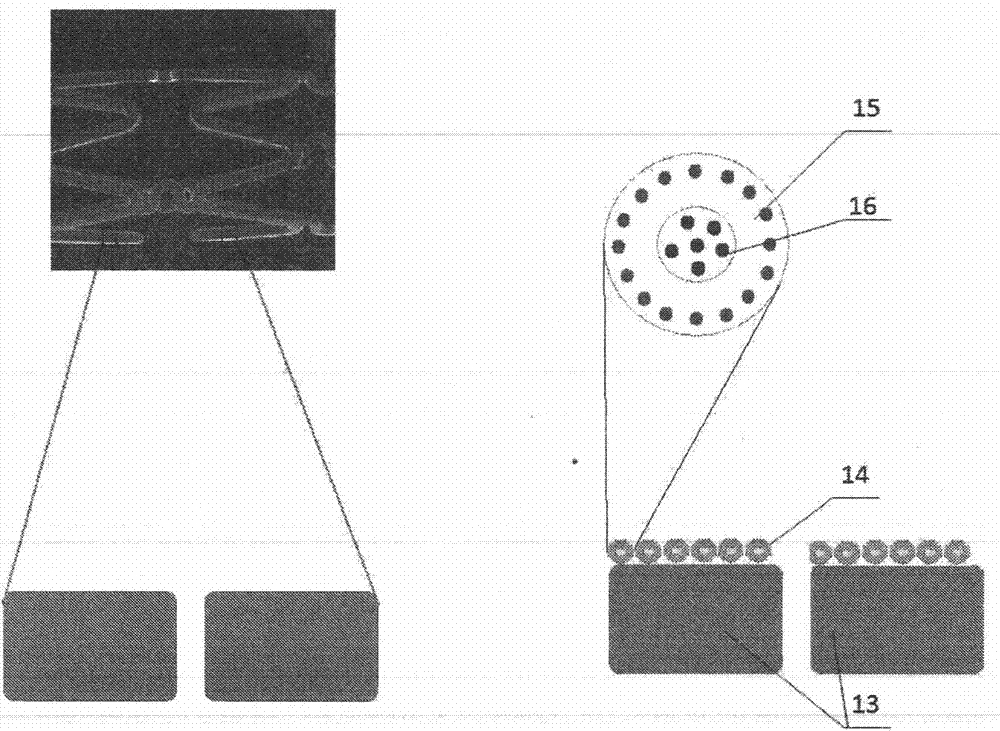

[0026] In this embodiment, the inner coating is β-elemene injection, and the outer coating is a chitosan-acetic acid solution of platelet membrane glycoprotein receptor IIIa antagonist sz-21, which is sprayed under corresponding experimental conditions.

[0027] (1) Put the 316L stainless steel bare metal bracket into 75% ethanol solution, acetone, and distilled water for 5-10 minutes, and then put it into 75% ethanol solution, acetone, and distilled water for 5-10 minutes to remove the residual oil, dust and other impurities on the surface of the bracket, and then soak it in chromic acid lotion 10-20min, then thoroughly cleaned with distilled water for 20min by ultrasonic oscillation, and then dried in a vacuum oven at 50°C for 24 hours.

[0028] (2) Take 2mg sz-21 powder and dissolve it in 1ml90% acetic acid solution, mix to make a drug solution, then weigh 20mg chitosan and dissolve it in the aforementioned 1ml drug solution, magnetically stir to make the chitosan dissolve c...

Embodiment 2

[0033] The inner coating of this embodiment is the PLGA electrospray liquid containing the antiproliferative drug docetaxel, and the outer coating is the chitosan acetate solution of the platelet membrane glycoprotein receptor IIIa antagonist sz-21, carried out under corresponding experimental conditions spraying.

[0034] (1) Put the 316L stainless steel bare metal bracket into 75% ethanol solution, acetone, and distilled water for 5-10 minutes, and then put it into 75% ethanol solution, acetone, and distilled water for 5-10 minutes to remove the residual oil, dust and other impurities on the surface of the bracket, and then soak it in chromic acid lotion 10-20min, then thoroughly cleaned with distilled water for 20min by ultrasonic vibration, and then dried in a vacuum oven at 50°C for 24 hours.

[0035] (2) Take 2mg sz-21 powder and dissolve it in 1ml90% acetic acid solution, mix to make a drug solution, then weigh 20mg chitosan and dissolve it in the aforementioned 1ml dru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com