Composite membrane and manufacturing method thereof

A composite membrane material and composite layer technology, applied in chemical instruments and methods, synthetic resin layered products, building components, etc., can solve the problems of thermal insulation system falling off, increased air leakage rate of vacuum insulation panels, and cement mortar layer debonding, etc. , achieve good fire resistance, improve heat resistance performance, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

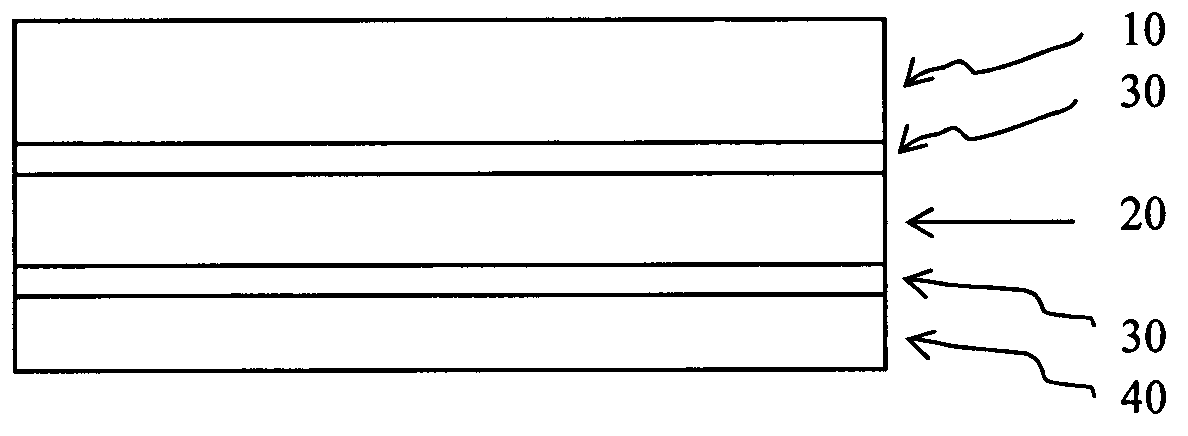

[0022] The inorganic fiber mesh cloth in the resin composite layer of inorganic fiber mesh cloth is 10 glass fiber mesh cloth, and the resin in the resin composite layer of inorganic fiber mesh cloth is polyethylene terephthalate. Magnesium hydroxide particles are added to the resin in the resin composite layer of the inorganic fiber grid cloth. The plastic composite layer is composed of polyethylene terephthalate and polyethylene film, with polyurethane adhesive between the layers.

[0023] The preparation method of the composite membrane material described in this embodiment is as follows:

[0024] (1) The resin particles are melted, and the melting temperature is 300° C. to obtain a resin melt;

[0025] (2) The additive is evenly added to the resin melt to obtain a mixed melt, and the mass ratio of the additive to the resin melt is 15:100;

[0026] (3) The mixed melt is introduced into the hopper, while the inorganic fiber mesh cloth is passed through the guide roller, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com