Preparation method of magnesium alloy surface micro-arc oxidation/spray coating compound film

A technology of micro-arc oxidation and magnesium alloy, which is applied to the device for coating liquid on the surface, anodizing, coating, etc. Area processing and other problems, to achieve the effect of good bonding, easy control of the preparation process, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

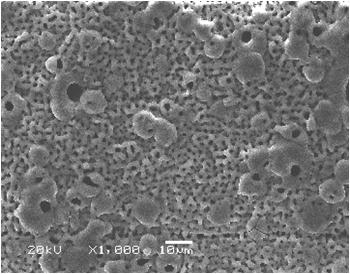

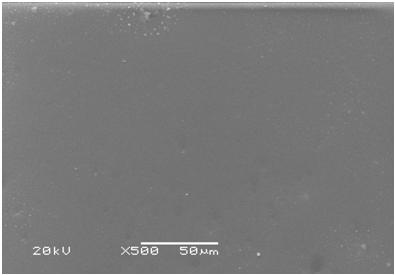

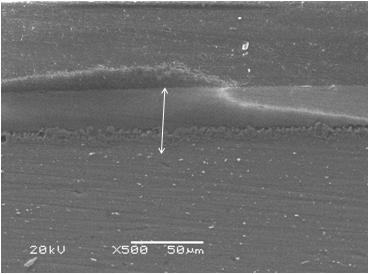

[0018]Specific Embodiment 1: The preparation method of the micro-arc oxidation / spray coating composite film on the surface of magnesium alloy in this embodiment is realized through the following steps: 1. The magnesium alloy is pretreated to remove the surface oxide film, and then the pretreated magnesium alloy is used as The working electrode is placed in the electrolyte, the stainless steel tank is used as the electrolytic cell and the counter electrode, and the constant voltage or constant current mode is used for micro-arc oxidation for 5-20 minutes, that is, a porous micro-arc oxidation ceramic film is obtained on the magnesium alloy, and the composition of the electrolyte is : 6~30g / L of Na 2 SiO 3 , 0~5g / L NaF and 0~5g / L NaOH, the solvent is water; in constant voltage mode, the control voltage is 350~550V, the frequency is 300~2000Hz, and the duty cycle is 10~45%; constant current mode, the control current density is 2~5A / dm 2 , the frequency is 300~2000Hz, and the du...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that the magnesium alloy in step 1 is AZ91D magnesium alloy, AZ31B magnesium alloy, magnesium-lithium alloy, MB26 or ZM5. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the magnesium alloy is pretreated in step 1: cleaning the surface of the magnesium alloy with decontamination powder, and then rinsing it with clean water, and the magnesium alloy after cleaning Grind and polish with 240#, 400#, 800# and 1000# water-resistant sandpaper in turn, and then wash with tap water, distilled water and acetone in turn. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com