Surface roughening treatment method of diamond

A technology of surface roughening and treatment methods, applied in the direction of chemical instruments and methods, surface etching compositions, etc., which can solve the problems of weak chemical bonding of diamonds and falling off of diamond particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

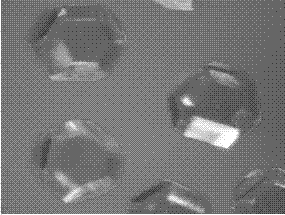

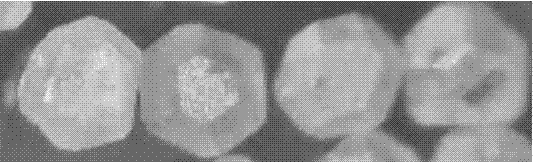

Image

Examples

Embodiment 1

[0019] A roughening treatment method for a diamond surface, comprising the steps of:

[0020] 1) Preparation of etching powder: in parts by mass, take 60 parts of corundum powder (particle size 5-20 μm), 1 part of potassium perchlorate (particle size 1-10 μm) and 20 parts of iron oxide powder (particle size 1-10 μm), Add to a mixer and mix evenly to obtain etching powder, set aside;

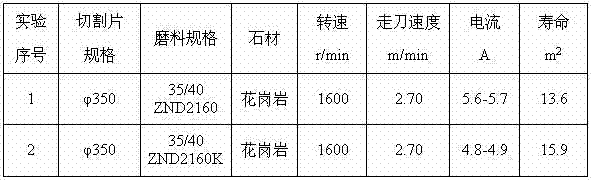

[0021] 2) Mixing: Take 1000g of diamond particles (Zhongnan Diamond Co., Ltd.) with a particle size of 35 / 40 and a brand name of ZND2160, pour them into a stainless steel bucket, first add 30ml of alcohol to wet the surface of the diamond particles, then add 300g of etching powder and stir uniform;

[0022] 3) Plate: Spread the material obtained in step 2) in a ceramic plate of 400mm×400mm×10mm (thickness is about 15mm);

[0023] 4) Heating: Put the porcelain plate into a muffle furnace (a muffle furnace with a heating chamber size of 500mm×500mm×500mm) for heating. The heating program is as fo...

Embodiment 2

[0026] A roughening treatment method for a diamond surface, comprising the steps of:

[0027] 1) Preparation of etching powder: In parts by mass, take 90 parts of corundum powder (5-20 μm in particle size), 2 parts of potassium perchlorate (1-10 μm in particle size) and 5 parts of iron oxide powder (1-10 μm in particle size), Add to a mixer and mix evenly to obtain etching powder, set aside;

[0028] 2) Mixing: Take 250g of diamond particles (Zhongnan Diamond Co., Ltd.) with a particle size of 35 / 40 and a brand name of ZND2160, pour them into a stainless steel bucket, first add 5ml of alcohol to wet the surface of the diamond particles, and then add 75g of etching powder and stir uniform;

[0029] 3) Plate: spread the material obtained in step 2) in a ceramic plate of 200mm×200mm×10mm (thickness is about 10mm);

[0030] 4) Heating: Put the porcelain plate into a muffle furnace (a muffle furnace with a heating chamber size of 300mm×300mm×300mm) for heating. The heating progra...

Embodiment 3

[0033] A roughening treatment method for a diamond surface, comprising the steps of:

[0034] 1) Preparation of etching powder: In parts by mass, take 70 parts of corundum powder (5-20 μm in particle size), 5 parts of potassium perchlorate (1-10 μm in particle size) and 10 parts of iron oxide powder (1-10 μm in particle size), Add to a mixer and mix evenly to obtain etching powder, set aside;

[0035] 2) Mixing: Take 600g of diamond particles (Zhongnan Diamond Co., Ltd.) with a particle size of 170 / 200 and a brand name of ZND2120, pour them into a stainless steel bucket, first add 40ml of alcohol to wet the surface of the diamond particles, and then add 600g of etching powder and stir uniform;

[0036] 3) Plate: Spread the material obtained in step 2) in a ceramic plate of 400mm×400mm×10mm (thickness is about 20mm);

[0037] 4) Heating: Put the porcelain plate into a muffle furnace (a muffle furnace with a heating chamber size of 500mm×500mm×500mm) for heating. The heating p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com