Aluminum-based circuit board and preparation method thereof, and full packaging electronic component

A technology for aluminum-based circuit boards and electronic components, which is applied to printed circuits connected to non-printed electrical components, removing conductive materials by chemical/electrolytic methods, and printed circuit components, etc. Poor strength, difficulty in roughening the alumina layer, etc., to achieve the effect of simplifying the process, overcoming the difficulty in roughening or being easily damaged by corrosion, and maintaining a stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

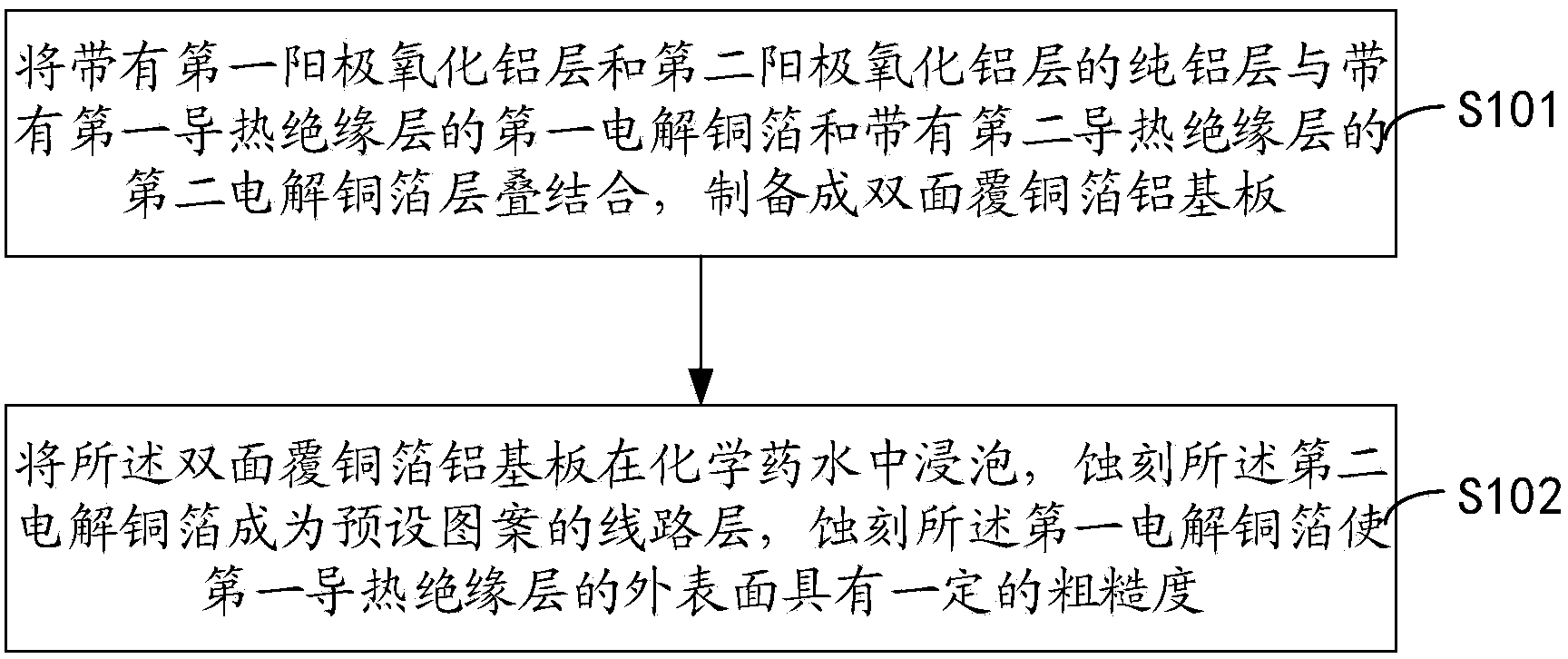

[0024] Correspondingly. The invention also provides a method for preparing an aluminum-based circuit board for preparing fully packaged electronic components with simple procedures and high production efficiency. This method can be used to prepare the above as figure 1 Shown aluminum base circuit board 1, the technique of this method is as image 3 shown, please also refer to figure 2 , which includes the following steps:

[0025] Step S101. Combine the pure aluminum layer 13 with the first anodized aluminum layer 12 and the second anodized aluminum layer 14 with the first electrolytic copper foil with the first thermally conductive insulating layer 11 and the second thermally conductive insulating layer 15 The second electrolytic copper foil is laminated and combined to prepare a double-sided copper-clad aluminum substrate;

[0026] Step S102. Soak the double-sided copper-clad aluminum substrate in chemical liquid, etch the second electrolytic copper foil combined with t...

Embodiment 1

[0045] An aluminum-based circuit board 1 for fully-packaged electronic components, a fully-packaged electronic component, and a preparation method for fully-packaged electronic components.

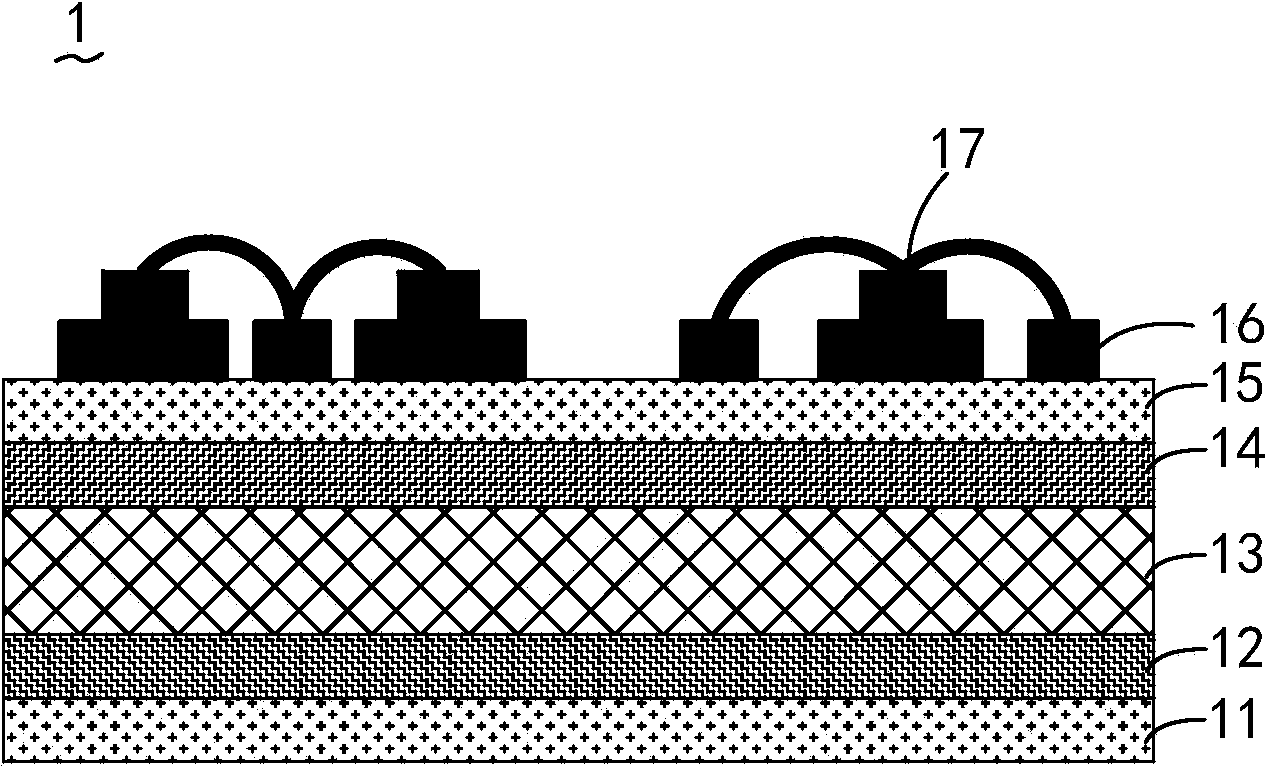

[0046] The structure of the aluminum base circuit board 1 is as follows: figure 1 As shown, it includes a first thermally conductive insulating layer 11, a first anodized aluminum layer 12, a pure aluminum layer 13, a second anodized aluminum layer 14, a second thermally conductive insulating layer 15 and a circuit layer that are sequentially stacked and combined 16 and electronic components 17 soldered on the circuit layer 16. Wherein, the thickness of the first thermally conductive insulating layer 11 is 75 μm, see Example 1 in Table 1 below.

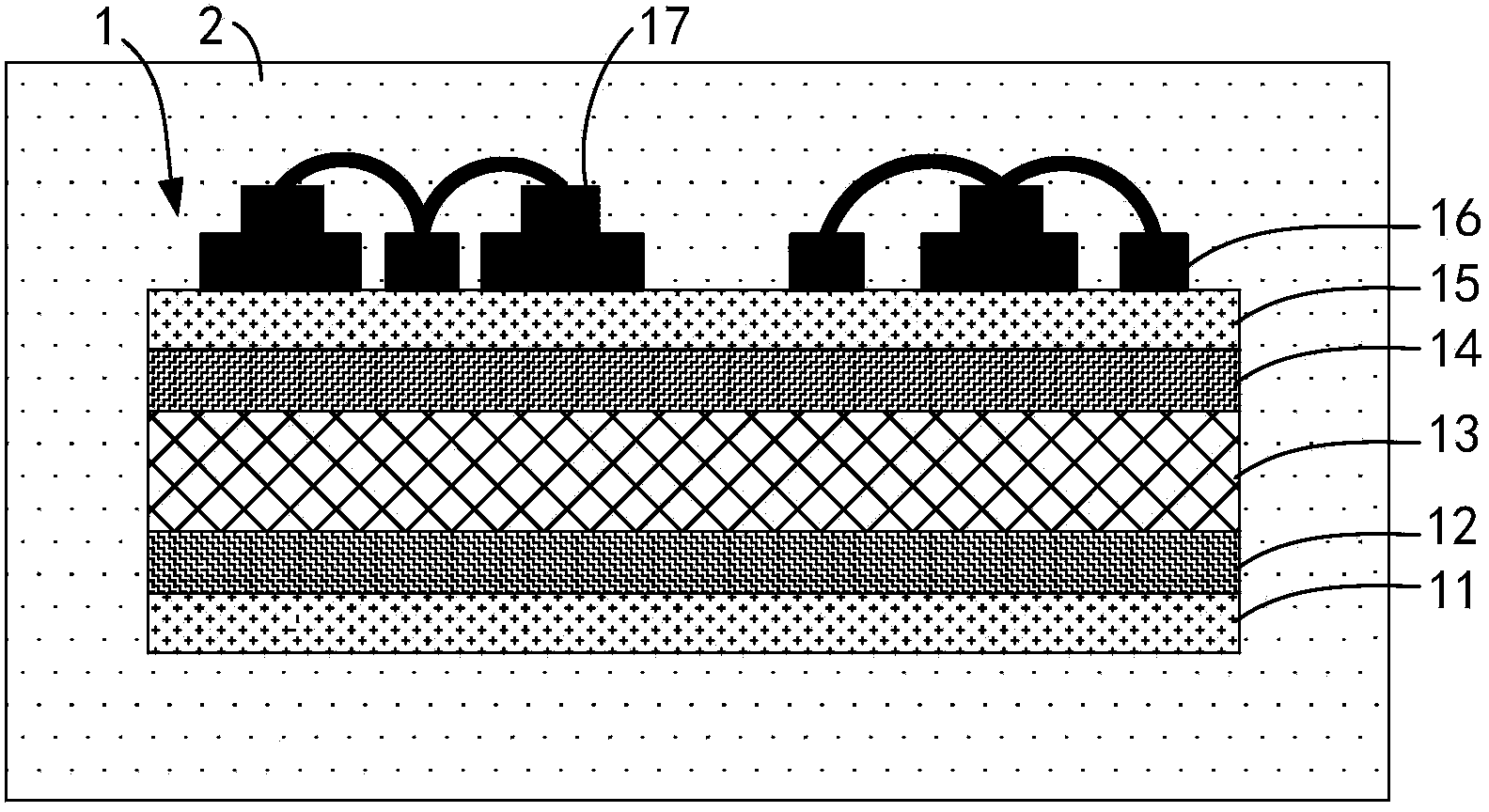

[0047] The fully encapsulated electronic components such as figure 2 As shown, its structure includes an aluminum-based circuit board 1 and an encapsulation layer 2 that fully encapsulates the aluminum-based circuit board.

[0048] The above-m...

Embodiment 2

[0053] An aluminum-based circuit board 1 for fully-packaged electronic components, a fully-packaged electronic component, and a preparation method for fully-packaged electronic components.

[0054] The structures of the aluminum-based circuit board 1 and the fully packaged electronic components are the same as those of the aluminum-based circuit board and the fully packaged electronic components in Embodiment 1. The difference is that the thickness of the first thermally conductive insulating layer 11 is 100 μm, see Example 2 in Table 1 below.

[0055] Refer to Example 1 for the above aluminum-based circuit board 1 and the preparation method of the fully packaged electronic components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com