Preparation method for aluminum plate base for direct plate making in inkjet printing

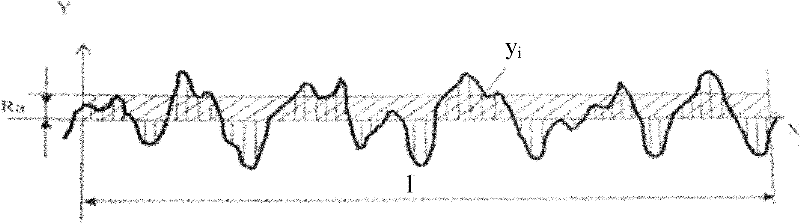

An inkjet printing, aluminum plate-based technology, applied in the field of printing plates, can solve the problems of large micropore pore size, decreased printing quality of printed matter, small porosity, etc., and achieves increased porosity, good ink absorption, and improved resolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Wash the aluminum base used for printing plates with water, degrease in a 40°C degreasing solution (40 wt% sodium hydroxide aqueous solution), and then neutralize the degreasing solution remaining on the aluminum base with 2 wt% dilute hydrochloric acid solution, Wash in hot water at 50°C.

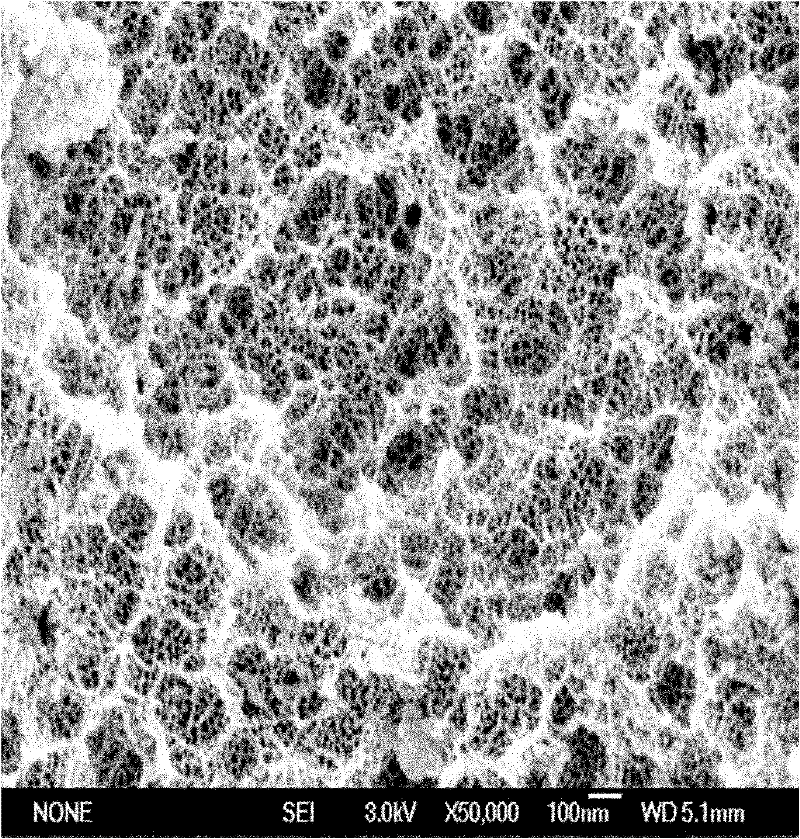

[0047] Put the above-mentioned degreased and cleaned aluminum substrate into the electrolytic solution for two electrolysis, the first electrolysis: the concentration of hydrochloric acid in the electrolytic solution is 0.5wt%, the concentration of tartaric acid is 1wt%, and the concentration of aluminum nitrate is 0.01 wt%, the balance is water, the electrolysis time is 80s, and the temperature of the electrolyte solution is 40°C; take it out and place it in the electrolyte solution for the second electrolysis: the concentration of hydrochloric acid in the electrolyte solution is 0.5wt%, and the concentration of tartaric acid is 1wt %, the concentration of aluminum nitrate is 2wt%,...

Embodiment 2

[0049] Wash the aluminum base used for printing plates with water, degrease in a 40°C degreasing solution (40 wt% sodium hydroxide aqueous solution), and then neutralize the degreasing solution remaining on the aluminum base with 2 wt% dilute hydrochloric acid solution, Wash in hot water at 60°C.

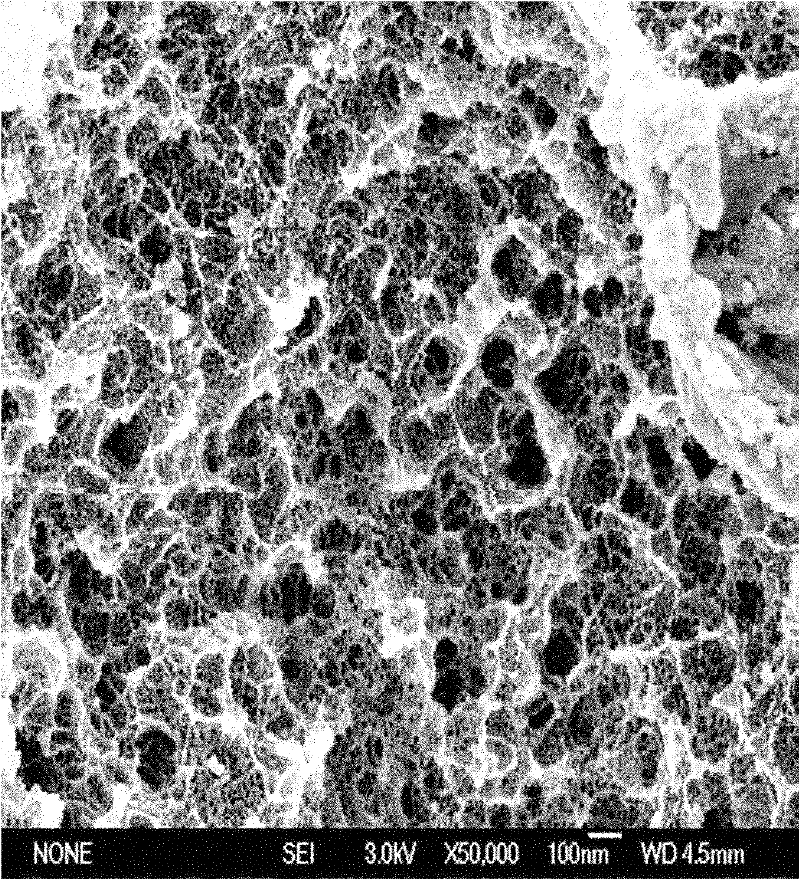

[0050] Put the above-mentioned degreased and cleaned aluminum plate base in the electrolytic solution for two electrolysis, the first electrolysis: the concentration of hydrochloric acid in the electrolytic solution is 8wt%, the concentration of phosphoric acid is 2wt%, and the concentration of acetic acid is 0.04wt%. , the concentration of ethylenediamine is 0.01wt%, the concentration of ethanolamine is 0.3wt%, the concentration of aluminum sulfate is 0.03wt%, the balance is water, the electrolysis time is 40s, and the temperature of electrolyte solution is 20 ℃; Carry out the second electrolysis in the electrolyte solution: the concentration of hydrochloric acid in the electrolyte...

Embodiment 3

[0052] Wash the aluminum base used for printing plates with water, degrease in a 40°C degreasing solution (40 wt% sodium hydroxide aqueous solution), and then neutralize the degreasing solution remaining on the aluminum base with 2 wt% dilute hydrochloric acid solution, Wash in hot water at 55°C.

[0053] Put the above-mentioned degreased and cleaned aluminum plate base in the electrolytic solution for two electrolysis, the first electrolysis: the concentration of hydrochloric acid in the electrolytic solution is 3wt%, the concentration of phosphoric acid is 2wt%, and the concentration of aluminum nitrate is 1wt%. , the concentration of cycloethylamine is 1wt%, the balance is water, the electrolysis time is 60s, and the temperature of the electrolyte solution is 30°C; take it out and place it in the electrolyte solution for the second electrolysis: the concentration of hydrochloric acid in the electrolyte solution is 0.3wt %, the concentration of phosphoric acid is 0.2wt%, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com