Metal material with low waviness surface and manufacturing method thereof

A metal material and waviness technology, applied in metal rolling and other directions, can solve problems such as surface texture regularity, moiré, coating defects, etc., and achieve the effect of reducing surface waviness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5 and comparative example 1-5

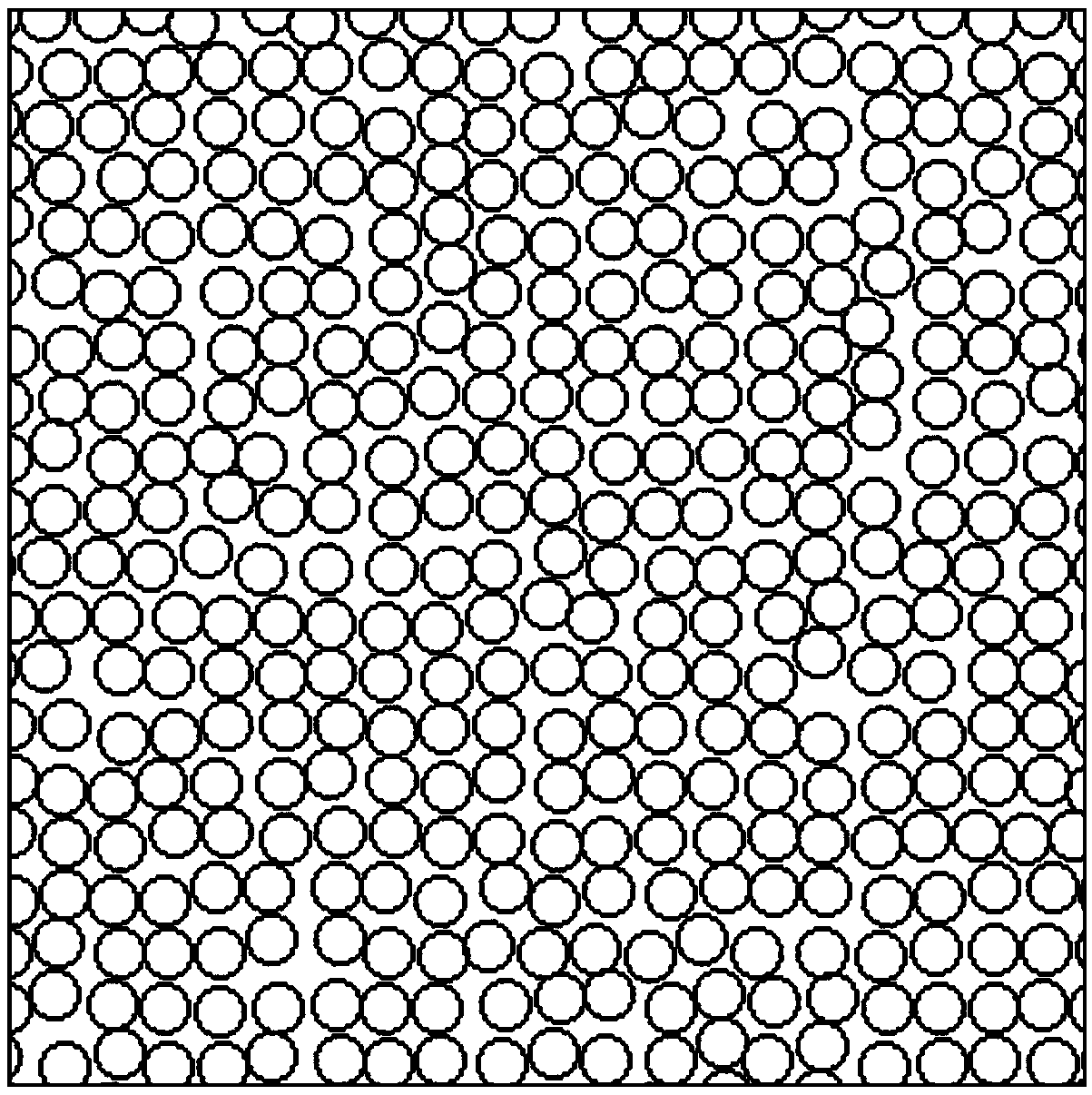

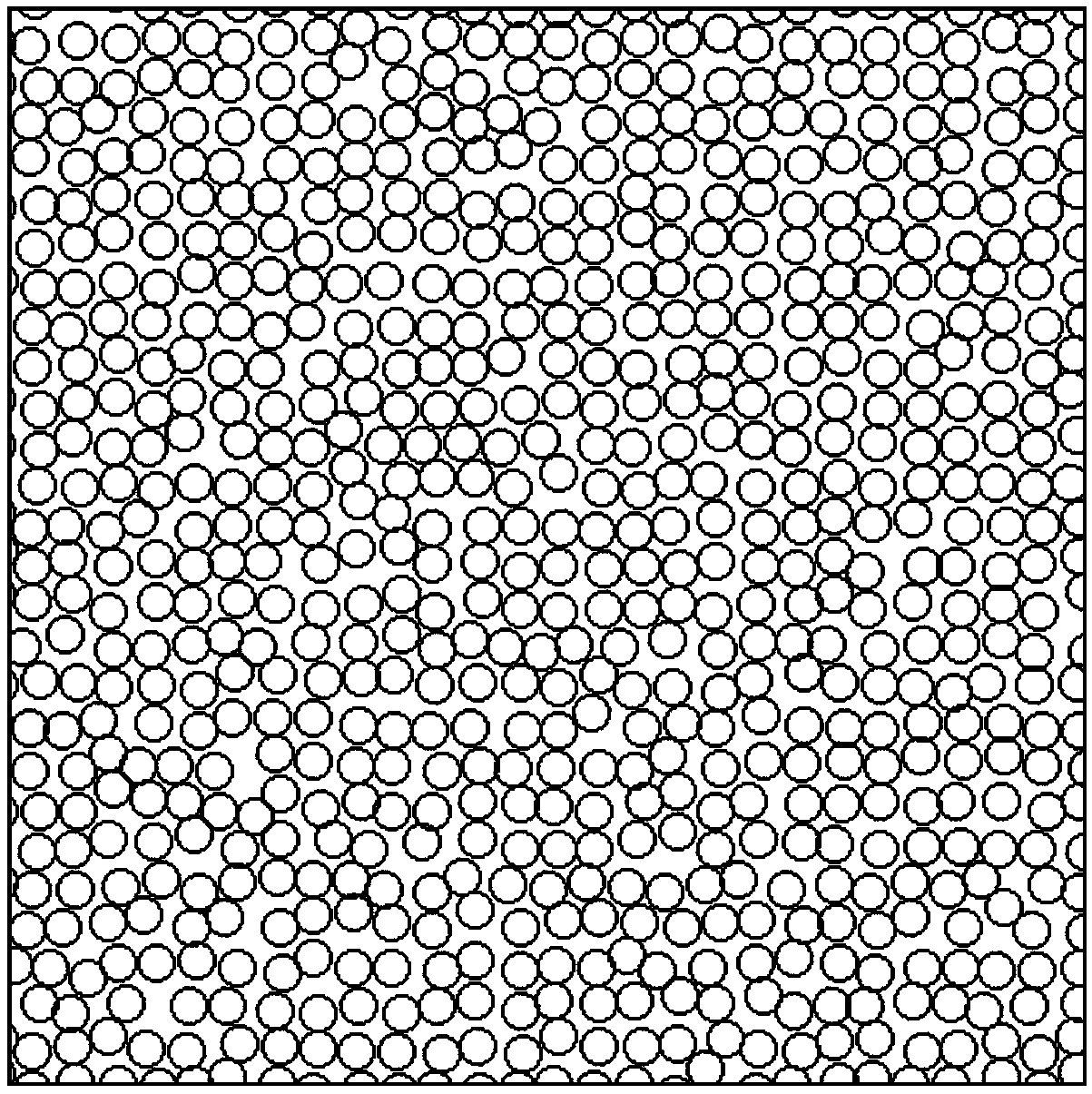

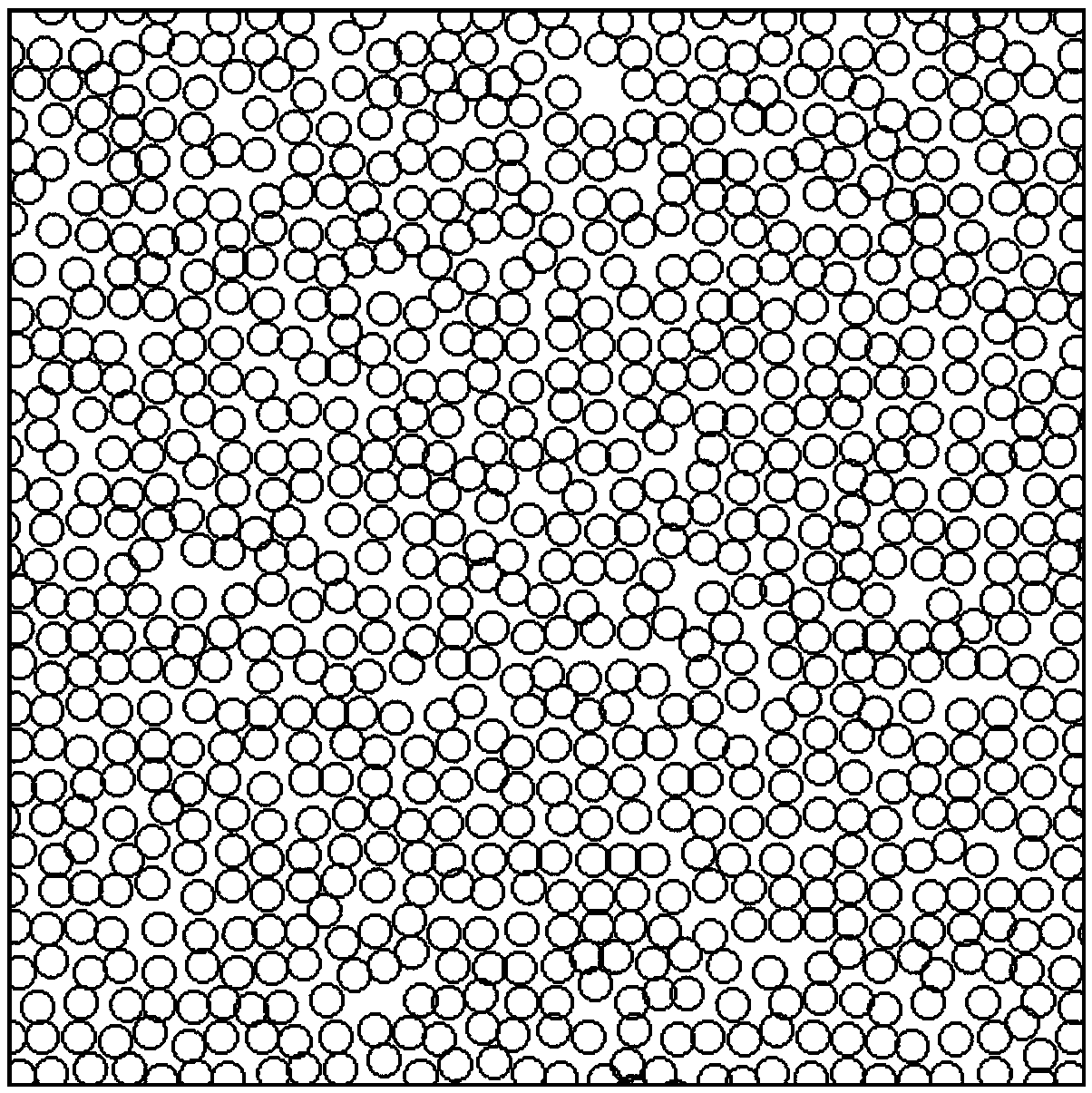

[0038] Examples 1-5 respectively adopt cold-rolled sheet, annealed flat sheet, and hot-dip galvanized flat sheet as the base material of the metal material, and design the surface morphology of the roll for rolling the base material, so that the surface of the roll has a large amount of roughening point, the area of a single textured point is 400~10000μm 2 ; The size difference between each textured point is less than 50%; the textured points are distributed randomly, and the overlapping amount between the textured points is less than 10%. The specific design parameters of roll surface topography can be found in Table 1.

[0039] Table 1.

[0040]

[0041] It should be noted that the area of the textured spot in Example 4 is 2260-3391 μm 2 , the purpose of which is to verify whether the obtained material still has low waviness when there is a significant difference in the texture point size.

[0042]Since the surface topography of the metal material is mainly copied ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com