Integrated basalt utilization system and process

A basalt and material technology, which is used in the separation of solids from solids by air flow, solids separation, sieves and other directions, which can solve the problems of a large number of equipment and a large consumption of spare parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples.

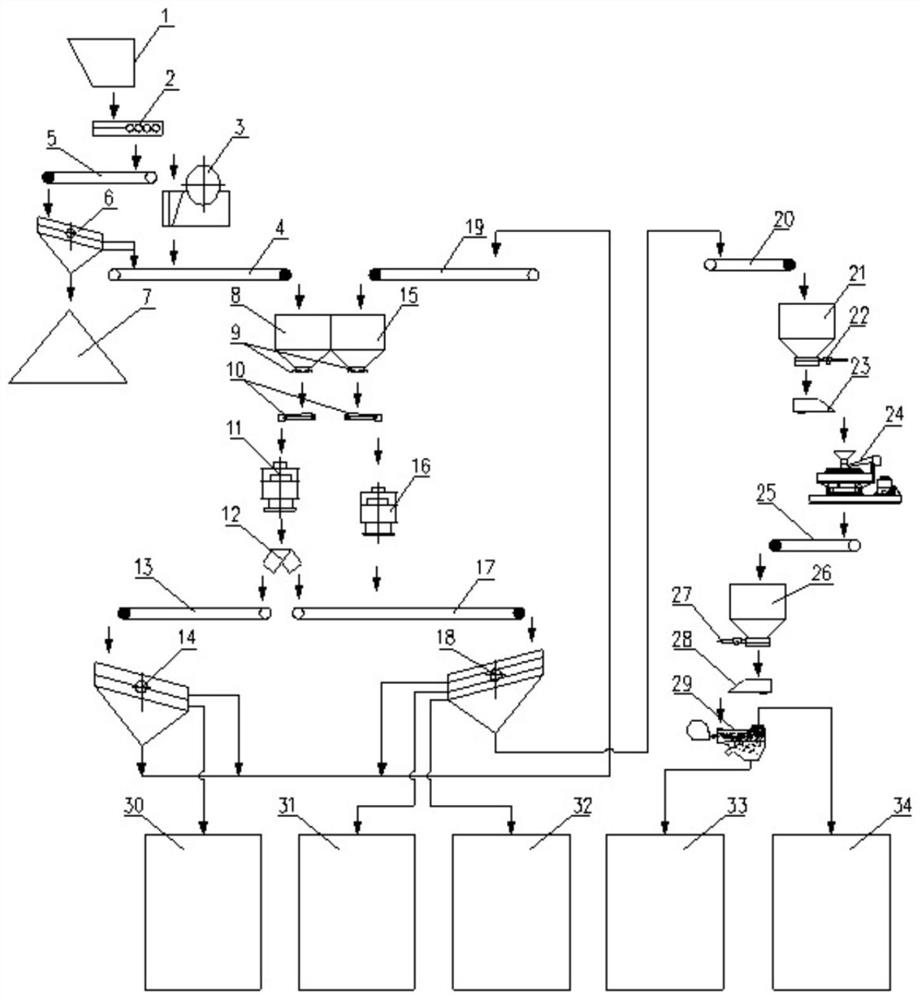

[0034] refer to figure 1 , a basalt comprehensive utilization system, comprising:

[0035] Raw ore warehouse 1;

[0036] The rod vibrating feeder 2 is installed under the raw ore bin 1. The material that does not pass through the rod gap of the rod vibrating feeder enters the jaw crusher 3 for coarse crushing, and the material discharged from the jaw crusher 3 enters the first belt. Conveyor 4; The material passing through the bar gap enters the soil removal screen 6 through the second belt conveyor 5;

[0037] The soil removal screen 6 adopts a double-layer circular vibrating screen. The materials on the upper part of the first and second screens enter the intermediate crushing buffer bin 8 through the first belt conveyor 4, and the intermediate crushing buffer bin 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com