Intelligent control system for stone-crushing and sand-making machine

An intelligent control system, sand making machine technology, applied in the direction of grain processing, etc., can solve the problems of low equipment efficiency, high energy consumption, etc., and achieve the effect of improving the speed of troubleshooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

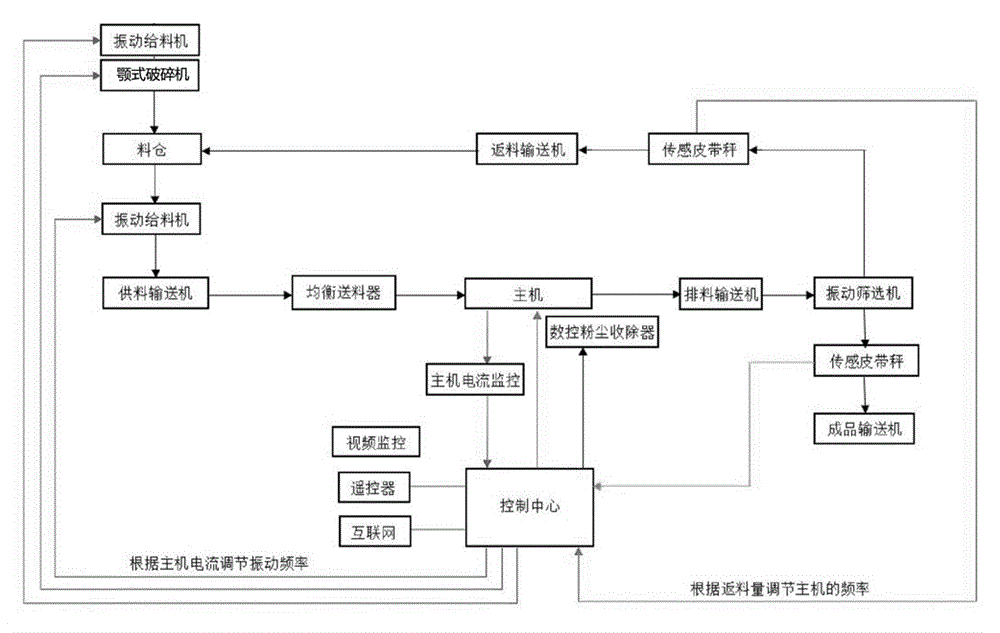

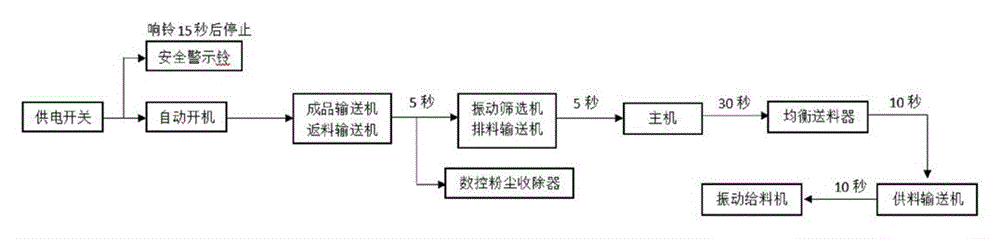

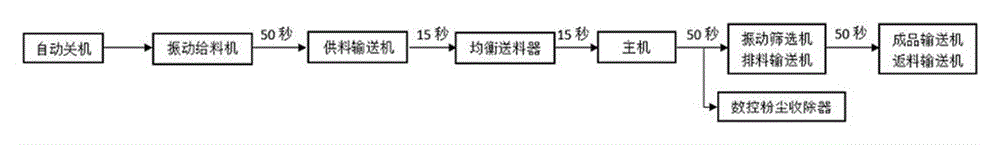

[0027] see Figure 1 to Figure 4, an intelligent control system for gravel sand making machine, the control center includes: power switch, central controller, regulated power supply, control signal converter, frequency conversion speed regulator, current detection and transmitter, AC contactor , Motor overload device, relay, hard disk video recorder, high-definition camera, monitor, switch, button and instrument. The control center is connected with the whole gravel sand making system and can control each equipment of the gravel sand making system to work. At the same time, it can be connected with the Internet and the remote control to monitor the whole gravel sand making system equipment in real time. The control center has two power-on operation control modes: manual adjustment mode and automatic adjustment mode.

[0028] The control center is firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com