High-strength high-crack-resistance anti-impact-wear concrete adopting basalt excavated materials as aggregates and preparation method of same

A basalt and concrete technology, applied in the field of concrete engineering, can solve the problems of wasting rock and mineral resources, occupying construction sites, etc., and achieve the effects of avoiding difficult construction, high strength growth, and excellent material combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

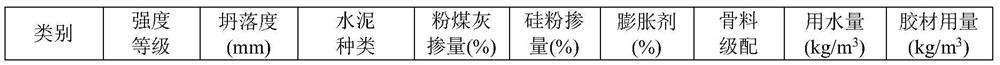

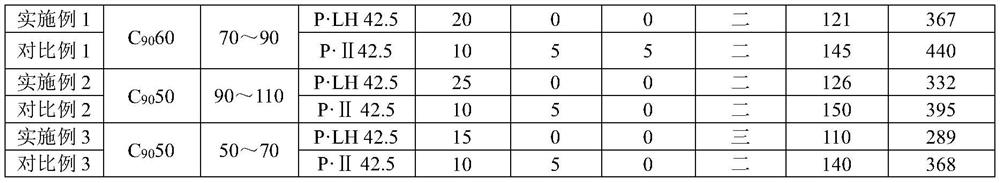

[0035] The projects involved are as follows:

[0036] The design label of the bottom plate concrete of the flood discharge tunnel of a certain hydropower station is C 9060F150W10 anti-scouring concrete is continuously loaded into the warehouse by a distributing machine for construction on site. Based on this, the design slump of the concrete is determined to be 70mm-90mm, the air content is 3.0%-4.0%, and the secondary aggregate is selected. The water-binder ratio of 0.33 and 20 % Fly ash content, 32% sand rate mix ratio parameters Carry out concrete mixture performance test, determine its construction mix ratio is - water: cement: fly ash: sand: crushed stone: water reducer: air entraining agent =121:294:73:659:1400:2.936:0.033 (kg / m 3 ).

[0037] According to the above-mentioned engineering design situation, a kind of high-strength and high-crack-resistant anti-abrasion concrete is required, and the concrete includes the following components by weight:

[0038] 294 parts ...

Embodiment 2

[0046] The projects involved are as follows:

[0047] The design label of the concrete surface layer of the pad pond floor of a hydropower station is C 90 50F150W8 anti-scouring concrete is constructed on site by hanging tanks into the warehouse and sliding formwork. Based on this, the design slump of the concrete is determined to be 90mm-110mm, the air content is 3.5%-4.0%, and the secondary aggregate is selected to be 0.38 water-cement ratio and 25%. Fly ash content, 34% sand rate mix ratio parameters Carry out concrete mixture performance test, determine its construction mix ratio as - water: cement: fly ash: sand: stone: water reducer: air entraining agent = 126 :249:83:694:1346:2.321:0.027(kg / m 3 ).

[0048] According to the above-mentioned engineering design situation, a kind of high-strength and high-crack-resistant anti-abrasion concrete is required, and the concrete includes the following components by weight:

[0049] 249 parts by weight of low-heat Portland cemen...

Embodiment 3

[0057] The projects involved are as follows:

[0058] The design label of the inner layer concrete of the pad pond floor of a hydropower station is C 90 50F150W8 anti-scouring concrete is constructed on site by hanging tanks into the warehouse and sliding formwork. Based on this, the design slump of the concrete is determined to be 50mm-70mm, the air content is 3.0%-3.5%, and the three-grade aggregate is selected. The water-binder ratio of 0.38 and 25% are selected. Fly ash content, 30% sand rate mix ratio parameters Carry out concrete mixture performance test, determine its construction mix ratio is - water: cement: fly ash: sand: stone: water reducer: air entraining agent = 110 :246:43:629:1469:2.026:0.023(kg / m 3 ).

[0059] According to the above-mentioned engineering design situation, a kind of high-strength and high-crack-resistant anti-abrasion concrete is required, and the concrete includes the following components by weight:

[0060] 246 parts by weight of low-heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com