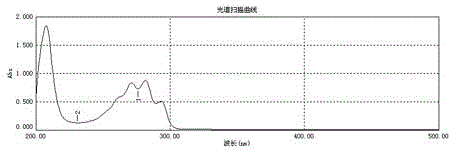

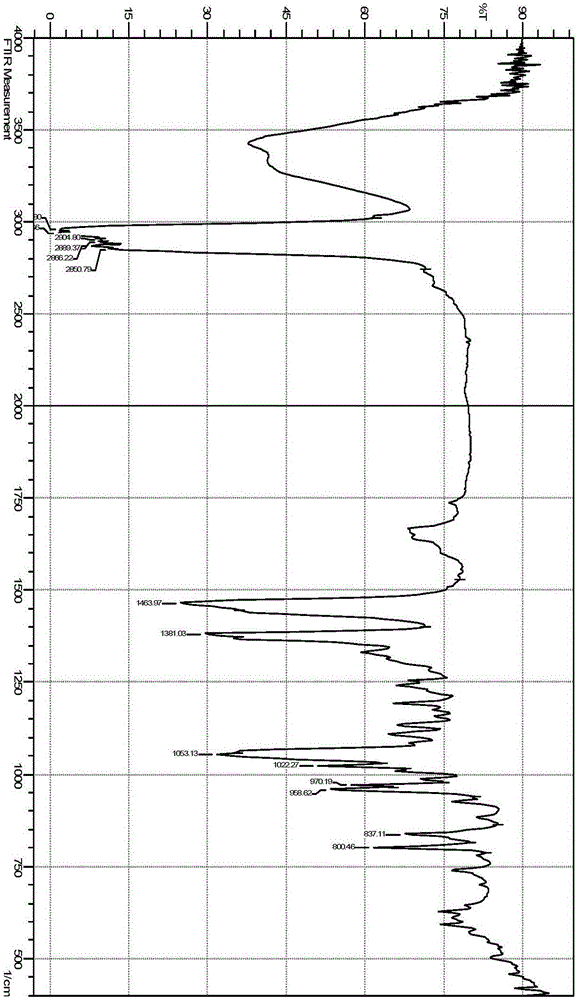

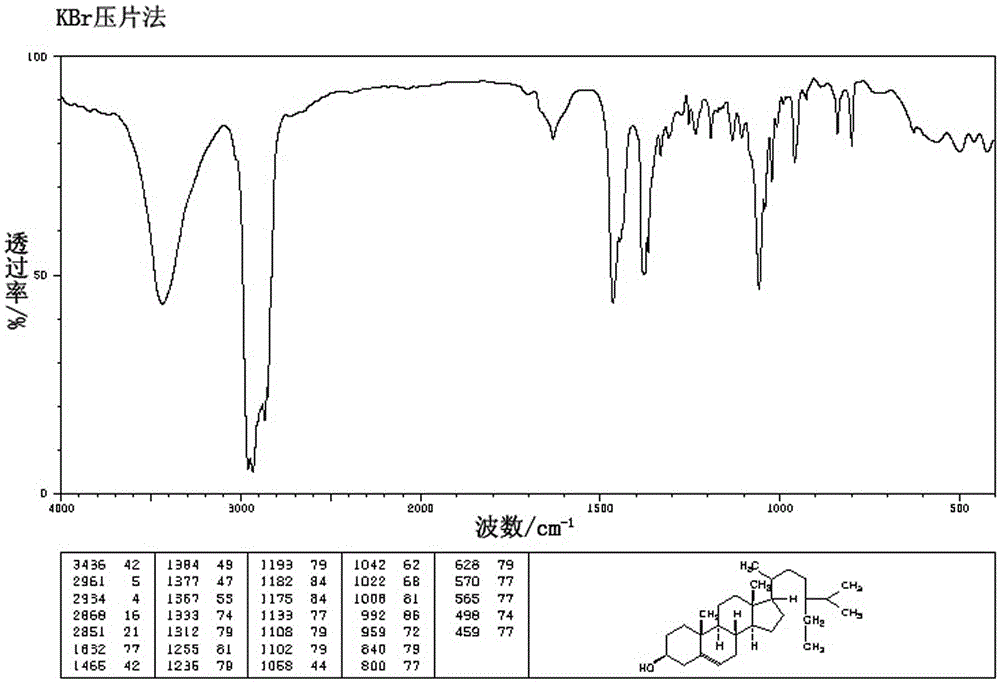

Method of separating sitosterol from extraction waste of fructus aurantii immaturus

A technology of waste and sitosterol, applied in the direction of steroids, organic chemistry, etc., can solve problems such as production limitations, and achieve high economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take 2000ml of citrus citrus extract waste, concentrate at 100°C under normal pressure, and get a concentration of 1.08g / cm 3 Concentrate 850ml, cool the concentrate to 65°C, add petroleum ether 850ml solvent in a 65°C water bath, stir and extract for 60 minutes, let it stand for 30 minutes, separate the petroleum ether extraction layer; repeat the extraction operation with 850ml petroleum ether for the water layer 2 The second time, the petroleum ether extracts were combined and allowed to stand for 2 hours. Wet-pack the column with an appropriate amount of petroleum ether and 600 g of chromatographic silica gel. Add the extract to the silica gel column, control the speed of the column, and use the 9:1 petroleum ether: ethyl acetate mixed solution mixed solvent to elute the extract after the column is completed. The eluate is collected when sitosterol is detected by crystallization From the eluate to the eluate, no sitosterol can be detected, and a total of 8500ml of ...

Embodiment 2

[0041] Take 2000ml of citrus citrus extract waste, concentrate at 100°C under normal pressure, and get a concentration of 1.07g / cm 3Concentrate 920ml, cool the concentrate to 65°C, add petroleum ether 920ml solvent in a 65°C water bath, stir and extract for 60 minutes, let it stand for 30 minutes, separate the petroleum ether extraction layer; repeat the extraction operation with 920ml petroleum ether for the water layer 3 The second time, the petroleum ether extracts were combined and allowed to stand for 2 hours. Wet-pack the column with an appropriate amount of petroleum ether and 600 g of chromatographic silica gel. Add the extract to the silica gel column, control the speed of the column, and use the 9:1 petroleum ether: ethyl acetate mixed solution mixed solvent to elute the extract after the column is completed. The eluate is collected when sitosterol is detected by crystallization From the eluate to the eluate, no sitosterol can be detected, and a total of 9000ml of t...

Embodiment 3

[0043] Take 2000ml of citrus citrus extract waste, concentrate at 100°C under normal pressure, and get a concentration of 1.08g / cm 3 The concentrated solution is 820ml. Cool the concentrated solution to 60°C, add 820ml of cyclohexane solvent in a 65°C water bath, stir and extract for 60 minutes, let it stand for 30 minutes, and separate the cyclohexane extraction layer; the water layer is repeated with 820ml of cyclohexane The extraction was performed 3 times, and the cyclohexane extracts were combined and allowed to stand for 2 hours. Use appropriate amount of cyclohexane and 600g chromatographic silica gel to wet pack the column. Add the extract to the silica gel column, control the speed of passing through the column. After the extract is passed through the column, use 95:5 cyclohexane: ethyl acetate mixed solution mixed solvent to elute. Collect the eluate until no sitosterol can be detected in the eluate, and collect 7300ml of the eluate in total. The eluate containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com