Method for producing mixed organic fertilizer from filtered mud

A technology of organic fertilizer and filter mud, which is applied in the preparation of organic fertilizer, organic fertilizer, and biological organic part treatment, etc., can solve the problems of slow fermentation of filter mud, burning seedlings of organic fertilizer, insufficient fertility, etc., so as to improve soil environment and save energy. Production cost, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with examples and accompanying drawings. It should be noted that the following embodiments are only illustrative, and are not intended to limit the present invention.

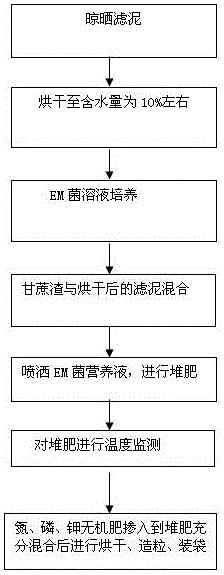

[0021] Such as figure 1 As shown, the method for producing mixed organic fertilizer from filter mud of the present invention firstly includes step S1, drying, and placing the filter mud removed from the production workshop in the open sun to dry to reduce the moisture therein. There is a lot of water in the filter mud, but the organic fertilizer requires low water content, so the filter mud must be dried, and direct drying will cause too much energy consumption, so add a drying step, using sunlight and wind to The filter mud is preliminarily dried.

[0022] Step S2, a drying step, using a hot air dryer to dry the filter mud. This step is to speed up the production of organic fertilizers. Natural drying takes time and cannot meet the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com