Multifunctional environment-friendly mortar modified by optimizing basalt admixture system and preparation method of multifunctional environment-friendly mortar

A technology of basalt and admixture, which is applied in the field of multifunctional low-cost environmentally friendly mortar materials and its preparation, can solve problems such as pollution, and achieve the effects of improving economic value, reducing porosity, and low porosity

Active Publication Date: 2021-06-29

浙江汇安工程质量检测有限公司

View PDF11 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] The purpose of the present invention is to provide an optimized basalt admixture system for modification to obtain multifunctional low-cost environmental

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

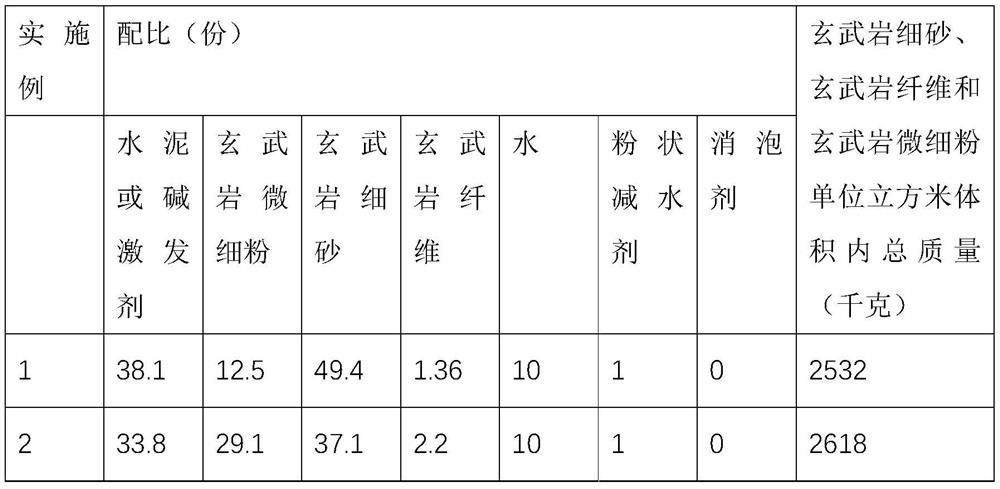

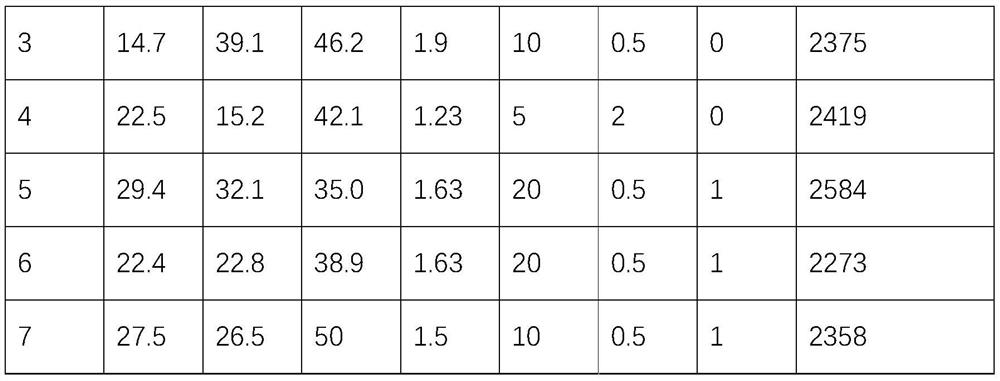

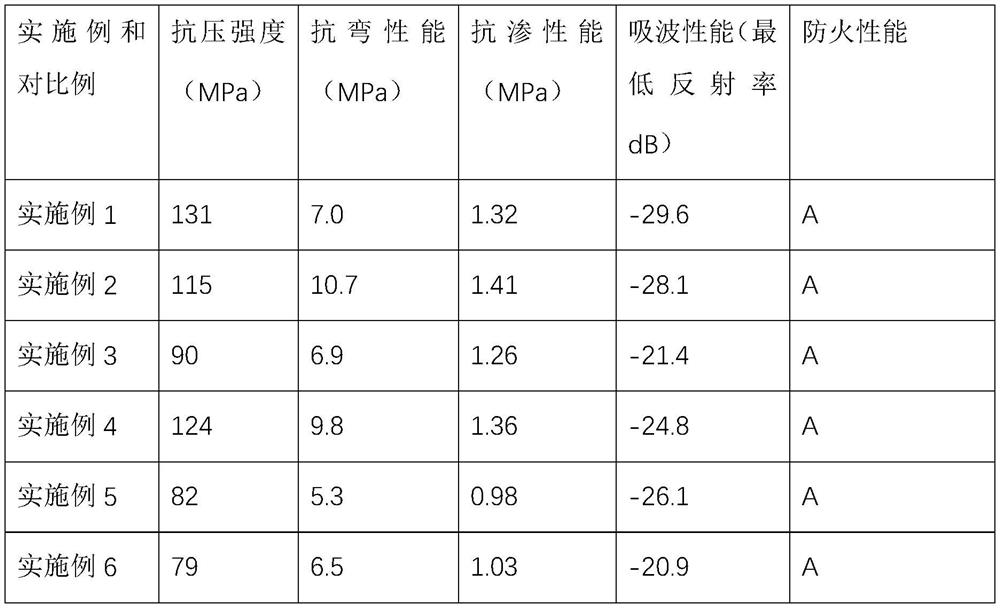

The invention relates to multifunctional environment-friendly mortar modified by optimizing a basalt admixture system. The multifunctional environment-friendly mortar comprises the basalt admixture system consisting of the fine basalt powder, fine basalt sand and basalt fiber, cement or alkali activator and water. The dry powder of the mortar is 100 parts by mass and comprises the following components in parts by mass: 1) 10-40 parts of the cement or alkali activator, 2) 10-40 parts of the fine basalt powder and 3) 30-50 parts of the fine basalt sand. Besides the dry powder, the basalt fiber accounts for 0-5 parts by mass and water accounts for 5-20 parts by mass. The invention further provides a preparation method of the multifunctional environment-friendly mortar modified by optimizing the basalt admixture system. The basalt admixture is doped into a material system of cement mortar, so the preparation energy consumption of the high-strength cement mortar is reduced, the working performance of the mortar is improved, and the application field of the high-strength cement mortar is expanded to the civil engineering material fields of national defense electromagnetic protection engineering, water conservancy engineering, fire-resistant construction engineering and the like.

Description

technical field [0001] The invention belongs to the fields of building materials, water conservancy projects and basic engineering construction, and relates to a multifunctional low-cost environmental protection mortar material modified by optimizing the basalt admixture system and a preparation method thereof. Background technique [0002] Due to better mechanical properties, high-strength cement mortar—as a kind of fine aggregate concrete—is gradually entering the stage of engineering application. However, the large amount of cement and poor flow properties are restricting the engineering application of high-strength cement mortar. At the same time, with the rise of the concept of green environmental protection, reducing the energy consumption of building materials has become a new topic in the building materials industry. How to save the amount of cement and improve the fluidity of high-strength cement mortar at low cost, and at the same time reduce the energy consumption...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/02C04B111/27C04B111/28C04B14/14C04B14/46

CPCC04B28/02C04B2111/28C04B2111/27C04B2111/00258C04B14/14C04B14/4656C04B2103/302C04B2103/50Y02W30/91

Inventor 沈满林沈亦农周丽肖管涛涛陈祖勇黄博滔

Owner 浙江汇安工程质量检测有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com