Mineral compound material and its use in sewage treatment

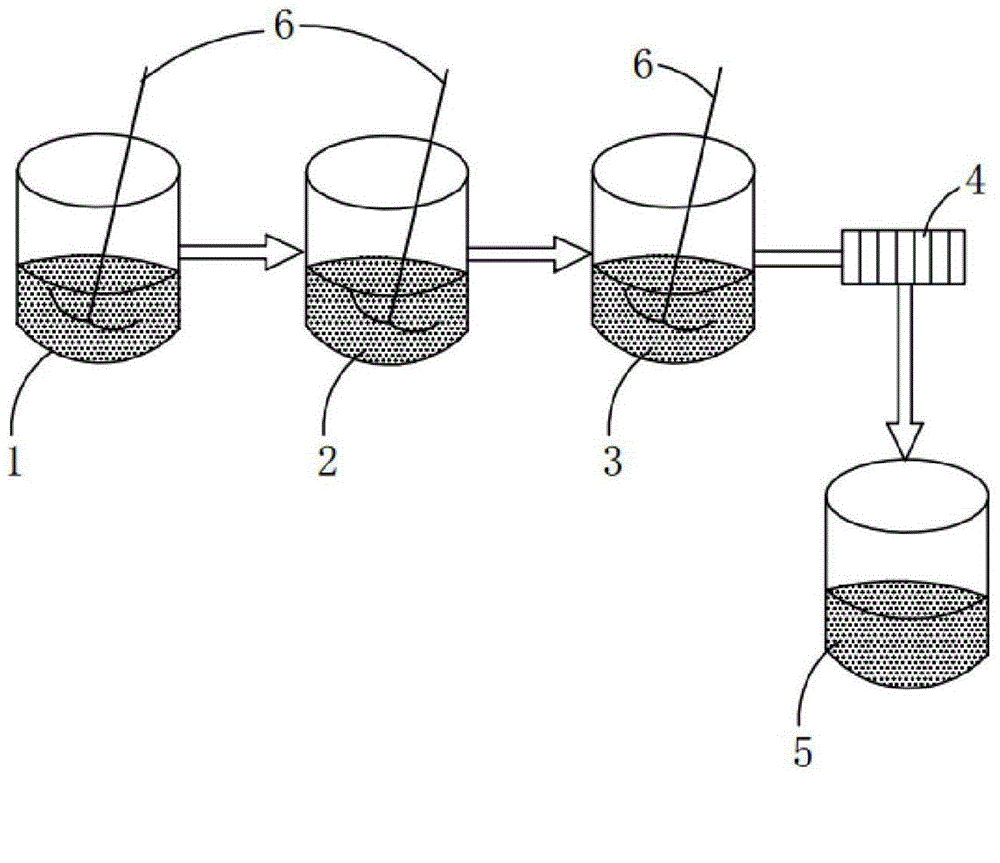

A sewage treatment and compound technology, applied in water/sewage treatment, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc., can solve the problems of complex equipment and high cost, and achieve the effect of simple equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]1. Preparation of mineral composite materials

[0044] Collect granite, basalt, peridotite and clay minerals. Granite, basalt, peridotite and clay minerals are pulverized and prepared into 1 cm granular shape. Weigh 15kg of granular granite, 12.5kg of basalt, 12.5kg of peridotite, and 15kg of clay minerals; then inject 4kg of 99% concentrated sulfuric acid, and the ingredients contained in the rocks and clay minerals are dissolved; then, add 10kg The water is stirred repeatedly to fully dissolve the ingredients in the rock and clay. After standing still for several days, the precipitated residue is filtered and separated from the aqueous solution to obtain the mineral composite material.

[0045] The mineral composite material prepared above was diluted 1000 times with pure water, and the metal components in the mineral composite material were quantitatively analyzed with the ICP emission analysis device VISTA MP-X according to the ICP emission analysis method. Potass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com