Method for predicting high-temperature viscosity and wire drawing temperature of basalt melt through viscosity modulus

A basalt and viscosity technology, applied in chemical property prediction, molecular entity identification, instruments, etc., can solve the problem of viscosity adjustment without quantitative basis, etc., and achieve the effect of being beneficial to comprehensive utilization, guaranteeing effect, guaranteeing control and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

[0034] 1. Viscosity measurement and prediction of basalt ore:

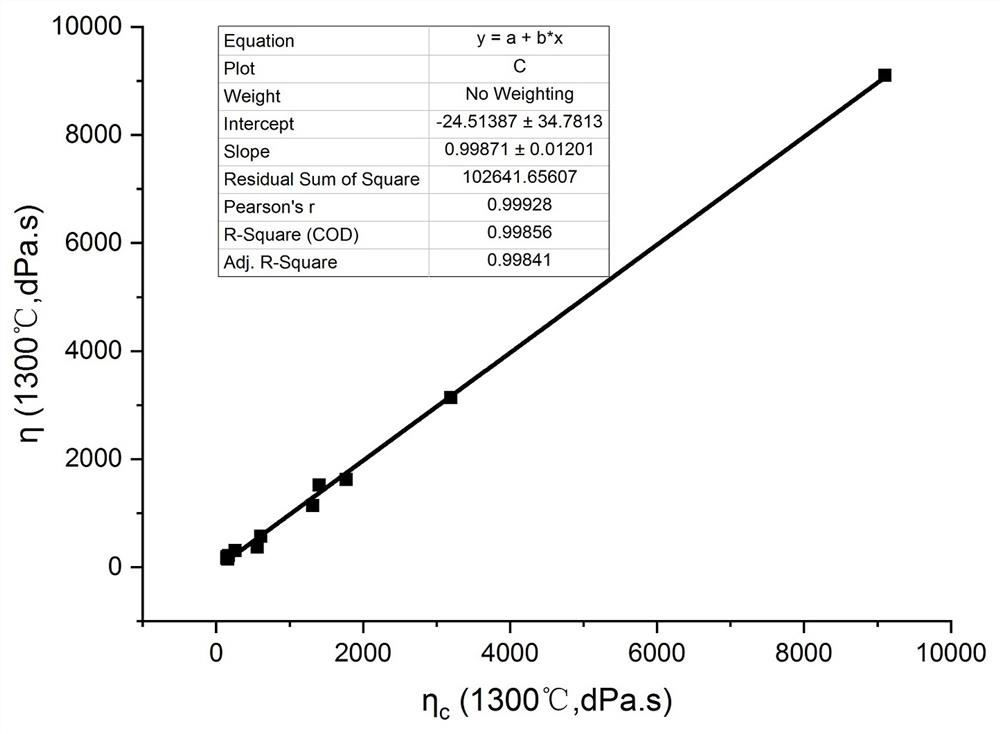

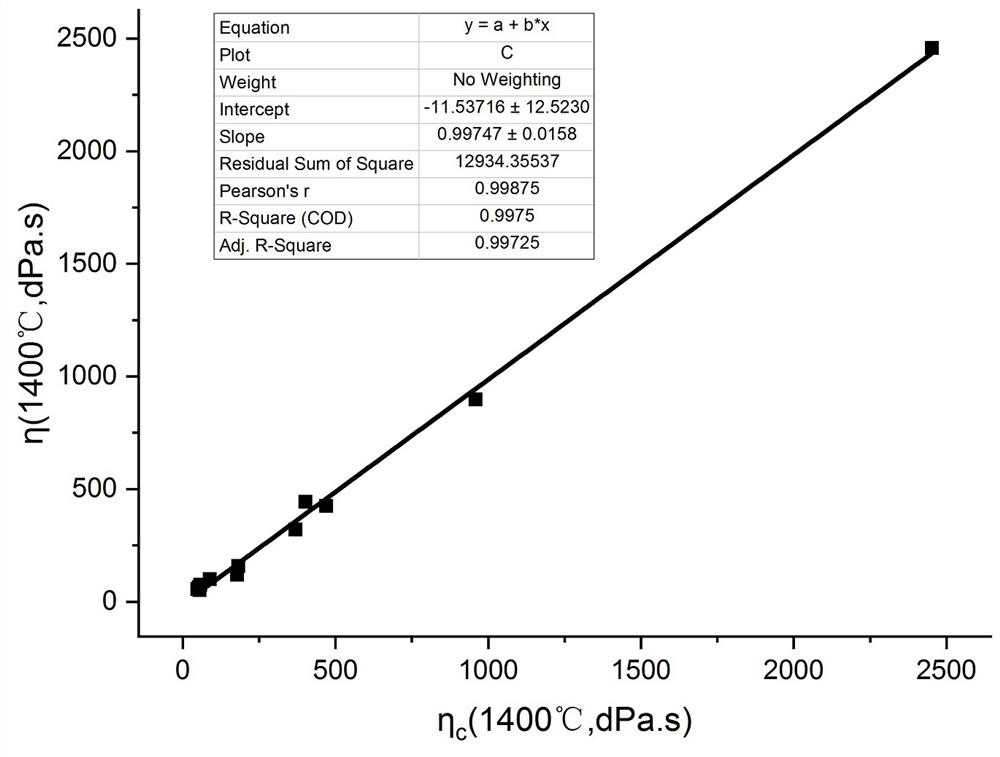

[0035] Collect 12 different basalt ores, wash the ores to remove impurities, continue to melt the ores at a high temperature of 1500°C for 10 hours until the composition is uniform, and then test the actual viscosity η at 1300°C and 1400°C under a high-temperature viscometer c (1300°C) and η c (1400 DEG C), determine various oxide content by component analysis, calculate the viscosity modulus Mη by the method of the present invention, the viscosity prediction value η (1300 DEG C) and η (1400 DEG C) of 1300 DEG C and 1400 DEG C, the result is as shown in the table 1 shows:

[0036] Table 1. Viscosity modulus of basalt, predicted and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com