Hybrid drive system and vehicle equipped therewith

A technology for hybrid driving and driving wheels, which is applied to hybrid vehicles, transmission devices, power devices, etc., can solve problems such as larger size, problems with vehicle mountability, and heavy weight, and achieve the effect of reducing fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

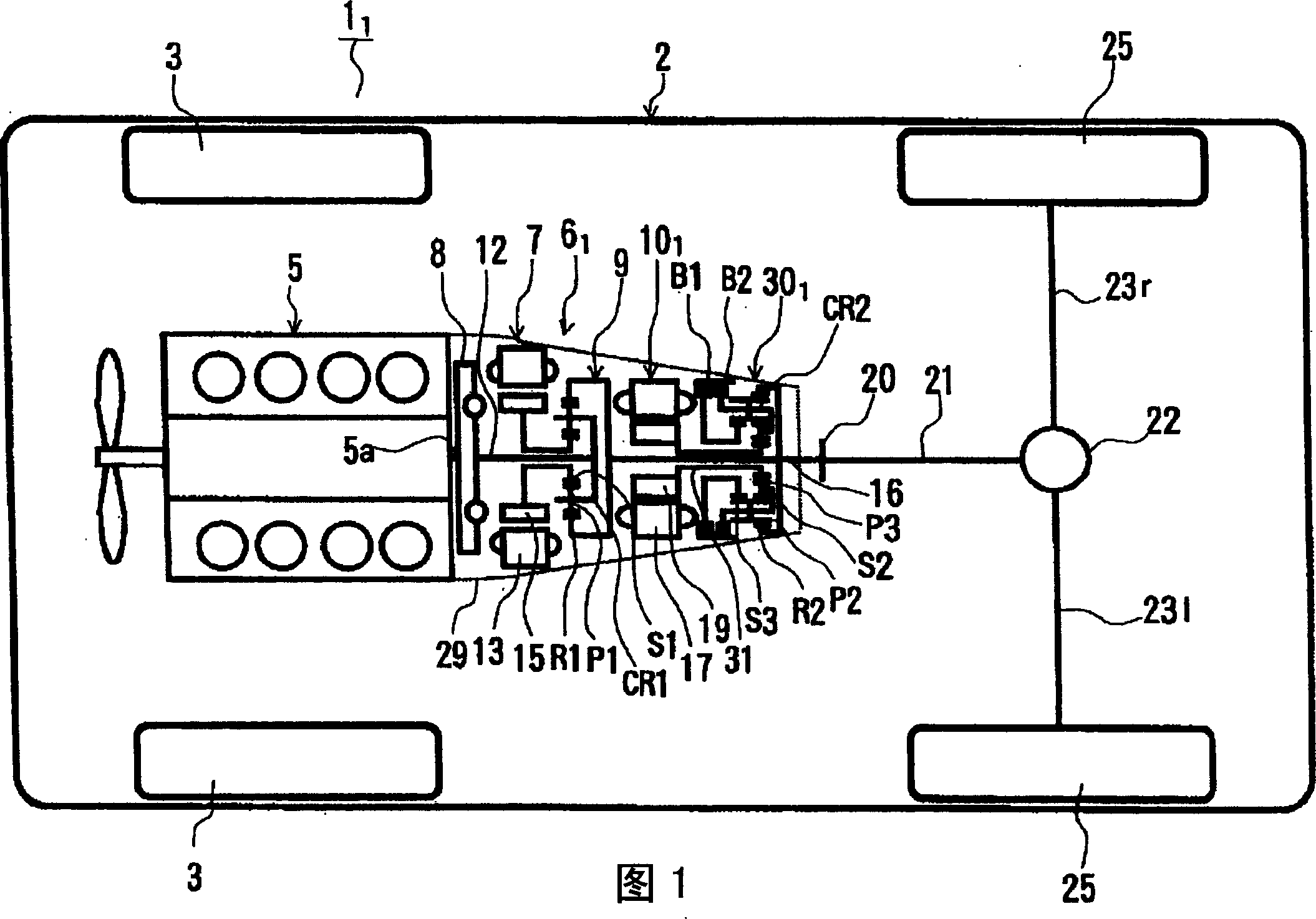

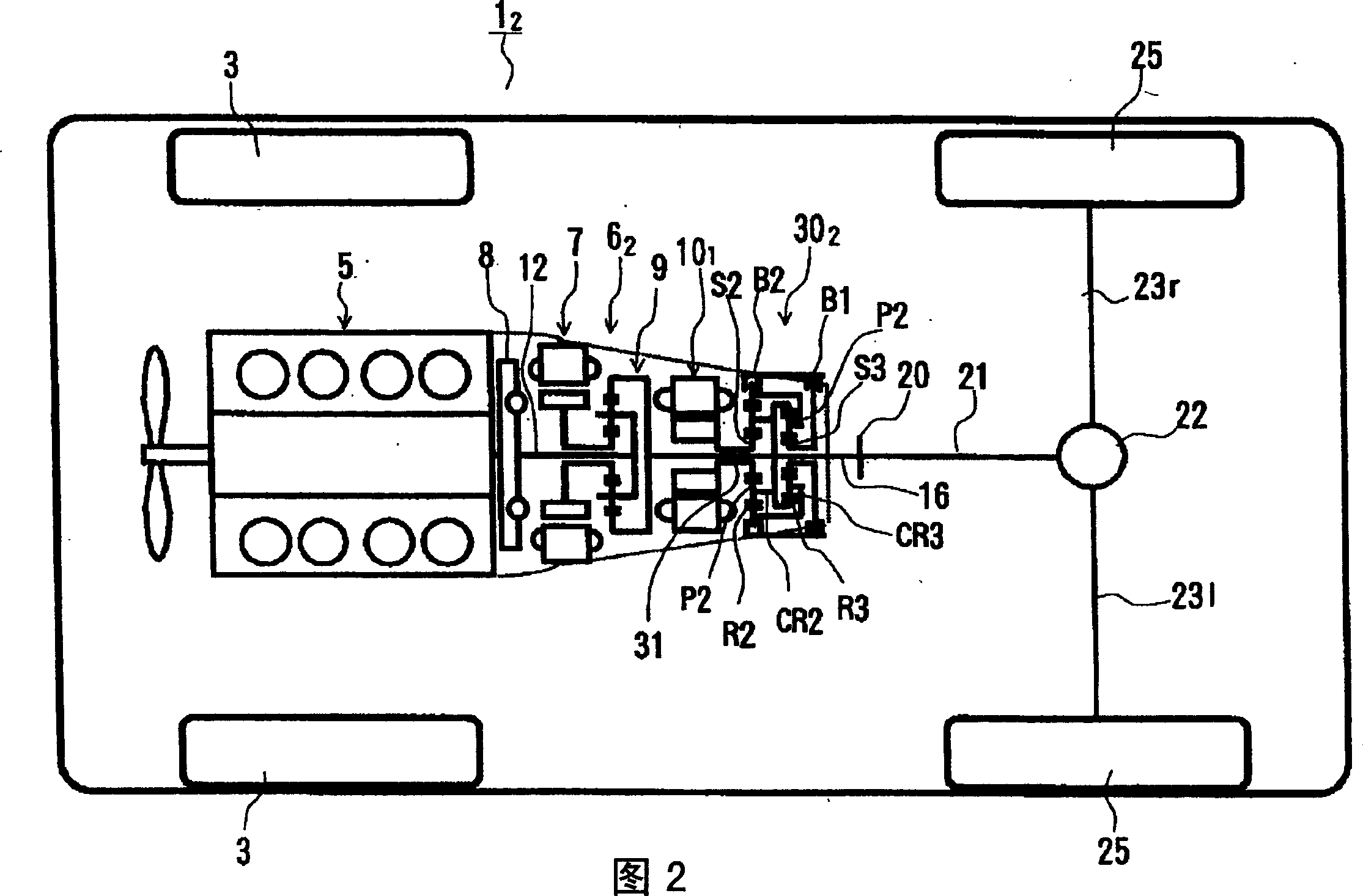

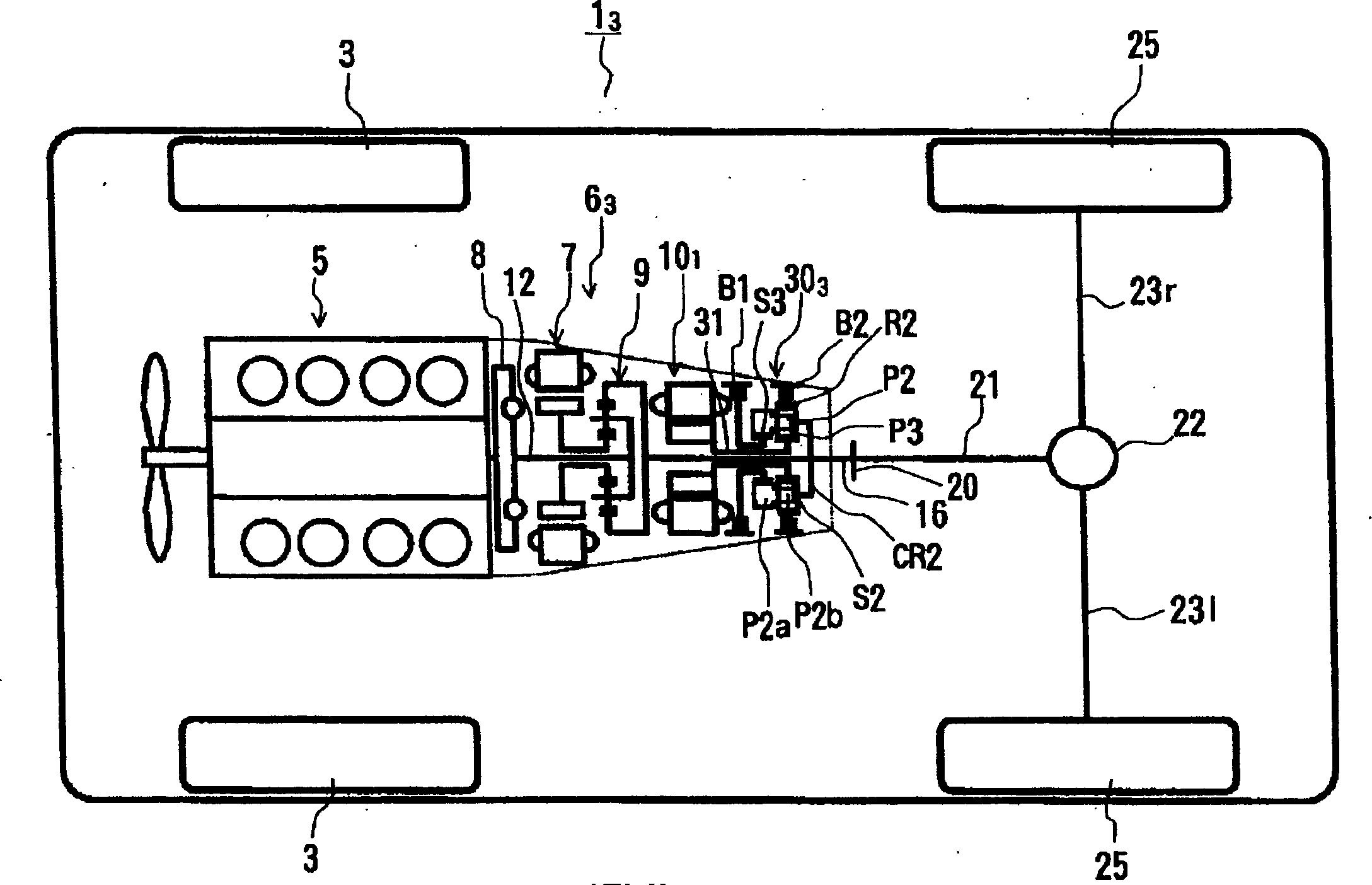

[0075] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Fig. 1 shows the schematic plan view of the FR automobile (embodiment 1) equipped with the hybrid driving device of the present invention, 1 1 Indicates that it is equipped with a hybrid drive unit 6 1 FR type car. the car 1 1 The car body 2 is suspended on the left and right front wheels 3, 3 and the left and right rear wheels 25, 25. At the front part of the car body 2, the internal combustion engine 5 is mounted on the crankshaft in the front-rear direction through a rubber mount.

[0076] Hybrid Drive 6 1 , same as above, aligned with the crankshaft from the engine 5 side and arranged on the same axis, the first electric motor (electric motor for control) 7, the planetary gear mechanism 9 for power distribution, and the second electric motor (electric motor for driving) 10 are sequentially arranged 1 , further on this basis in the second motor 10 1 The transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com