Artificial false roof construction method of built-in basalt fiber geogrid reinforced structure

A technology of basalt fiber and geogrid, which is applied in the direction of earthwork drilling, safety devices, fillings, etc., can solve the problems of poor compatibility of filling body reinforcement, cumbersome construction, easy separation, etc., achieve high interface connection strength, reduce steel Effect of usage amount and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

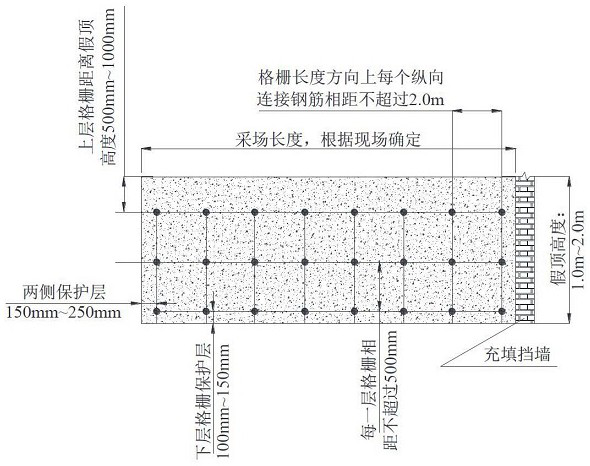

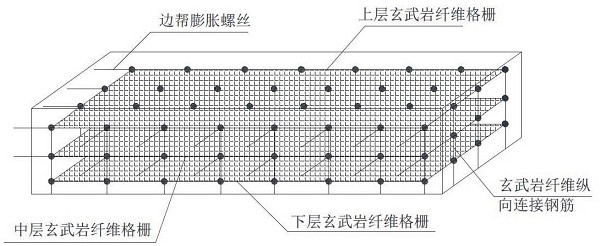

[0025] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0026] The present invention aims at the problems of long period, cumbersome construction, poor compatibility of the reinforcement of the filling body, easy separation and the like in the current filling false roof construction, and provides an artificial false roof construction method with a built-in basalt fiber geogrid reinforcement structure.

[0027] The method includes steps as follows:

[0028] (1) After the mining is completed, level the site, clean up the large waste rocks existing in the approach, and deal with the two groups of protruding pumice;

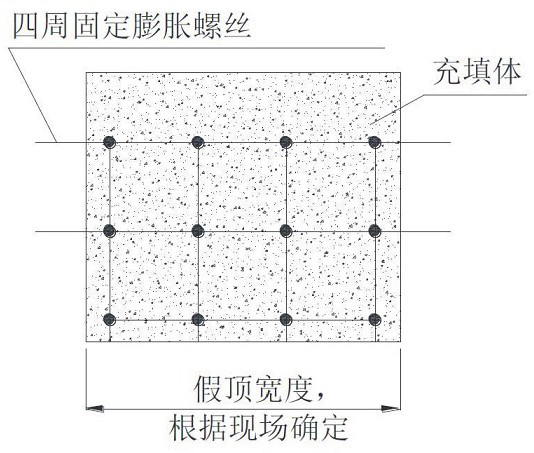

[0029] (2) Cut the basalt fiber grid according to the size of the stope to ensure that the basalt fiber grid is a whole in the span and length direction of the stope, and cut three pieces of basalt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com