Ceramic material, digital glaze spraying ceramic rock plate as well as preparation method and application of digital glaze spraying ceramic rock plate

A ceramic material and digital technology, applied in the field of digital spray glazed ceramic slate and its preparation, and ceramic material, can solve the problems of poor high temperature resistance, acid and alkali resistance, obvious water ripples, small molding pressure, etc., to achieve scratch resistance and wear resistance. Superior performance, simple process and operation, and the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

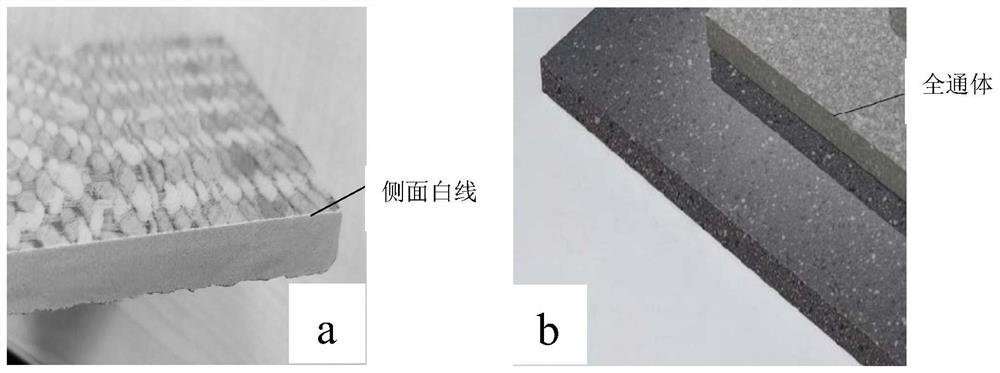

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1 ceramic material and the preparation of digital spray glaze ceramic rock plate

[0033] Preparation of ceramic material: take raw material formula by weight percentage, quartz 30%, talcum powder 10%, potassium feldspar 10%, kaolin 2%, basalt 40%, black pigment 7.87% and sodium humate 0.2%, after Mixing, ball milling and spray drying to obtain the finished product 1 of the ceramic material embodiment.

[0034] Preparation of digital glazed ceramic rock slab: take the finished product 1 of the ceramic material embodiment, place it in the mold core of a 10,000-ton press, press the ceramic material under a pressure of 15000T, and obtain a green body; polish the surface of the green body Treatment, throwing off a thickness of 0.1mm, drying at 110°C to obtain a green body layer; applying digital glaze on the green body layer; applying transparent glaze by high-definition inkjet, and drying at 1200°C Firing for 150-200 minutes; finally, after p...

Embodiment 2

[0035] The preparation of embodiment 2 ceramic material and the preparation of digital spray glaze ceramic rock plate

[0036]Preparation of ceramic material: Weigh the raw material formula by weight percentage, 35% of quartz, 15% of talcum powder, 8% of potassium feldspar, 2% of kaolin, 35% of basalt, 4.7% of gray pigment and 0.3% of functional additive for flexural strength , through mixing, ball milling and spray drying, the finished product 2 of ceramic material embodiment was obtained.

[0037] Preparation of digital glazed ceramic rock slabs: Take the finished product 2 of the ceramic material embodiment, and use a 10,000-ton press to press the ceramic material under a pressure of 25,000T to obtain a green body; the surface of the green body is polished, and the thickness of the polished body is 0.2m, dried at 120°C to obtain a green body layer; on the green body layer, digital spray glaze is used to apply surface glaze; high-definition inkjet method is used to apply tra...

Embodiment 3

[0038] The preparation of embodiment 3 ceramic material and the preparation of digital spray glaze ceramic rock plate

[0039] Preparation of ceramic material: Weigh the raw material formula by weight percentage, 45% of quartz, 10% of talcum powder, 10% of potassium feldspar, 3% of kaolin, 25% of basalt, 6.8% of brown color material and 0.2- 0.3%, after mixing, ball milling and spray drying, the finished product 3 of the ceramic material embodiment was obtained.

[0040] Preparation of digital glazed ceramic rock slabs: Take the finished product 3 of the ceramic material embodiment, and use a 10,000-ton press to press the ceramic material under a pressure of 30,000T to obtain a green body; the surface of the green body is polished, and the thickness of the polished body is 0.3mm, dried at 130°C to obtain a green body layer; on the green body layer, digital spray glaze is used to apply surface glaze; high-definition inkjet method is used to apply transparent glaze, and fired at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com