High-quality basalt machine-made sandstone aggregate production line and technological process thereof

A basalt, production line technology, applied in solid separation, sieve, grid and other directions, can solve the problems of low content of finished sand and gravel powder, unbalanced production, unqualified quality, etc., to achieve suitable fineness modulus, easy adjustment, basic simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

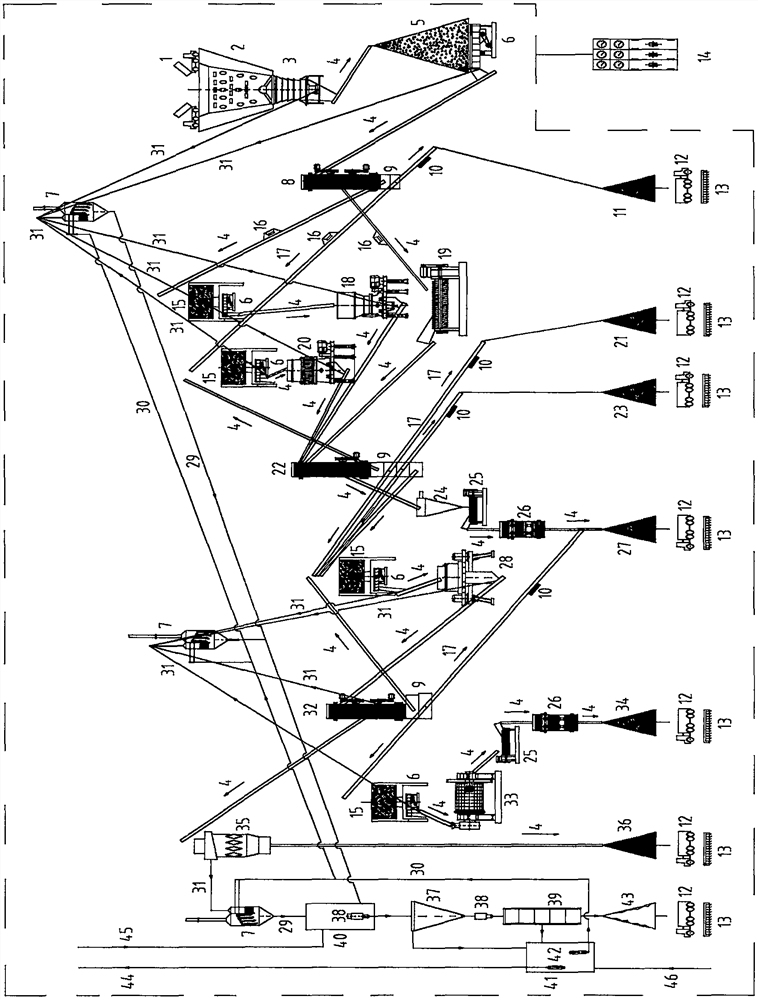

[0054] figure 1 Among them, the hydraulic gyratory crusher (3) is installed under the raw stone receiving pit (2), and its discharge port is connected to the coarse aggregate semi-finished material pile (5) through the connection of the one-way belt conveyor (4). A reinforced concrete conveying corridor is set up under the coarse aggregate semi-finished product stockpile (5), and a vibrating feeder (6) is suspended in the corridor, and the vibrating feeder (6) is connected to the circular feeder (6) through the one-way belt conveyor (4). The feeding end of vibrating water washing pre-sieve (8) joins. The first-layer sieve of the circular vibrating water-washed pre-screen (8) acts as a buffer protection; the first and second-layer sieves share the hopper (9) through the connection of the one-way belt conveyor (4) to communicate with the intermediate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com