Dust control method and intelligent environment-friendly bulk material storage and transportation system

A dust control and control system technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of lack of dust removal unit, no energy saving and environmental protection, waste of dust removal raw materials/medium, etc., to achieve reasonable operation and avoid pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

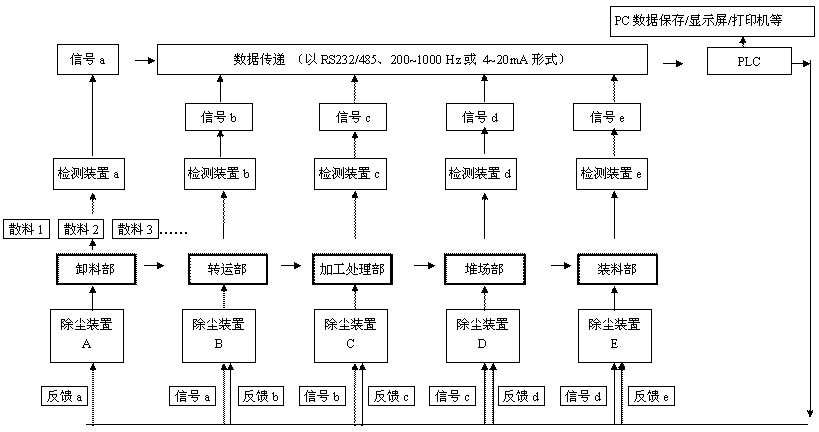

[0022]Such as figure 1 The intelligent environment-friendly bulk material storage and transportation system shown includes detection devices a, detection Device b, detection device c, detection device d, detection device e, and dust removal device A, dust removal device B, dust removal device C, dust removal device D, dust removal device E, etc.; the PLC control system for the operation of each dust removal device; the dust concentration of each air The detection device is used to collect the air dust concentration data; the collected data is fed back to the PLC control system through the data line or wireless signal, and the data transmission method can adopt RS232 / 485 communication protocol, 200~1000 Hz or 4~20mA and other transmission methods. The unloading department includes the unloading room and unloading equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com