Modified basalt-flake impermeable concrete and preparation method thereof

A technology of impervious concrete and basalt, which is applied in the field of building materials, can solve the problems of reducing the durability of concrete structures, losing the load capacity and functional requirements of concrete structures, economic losses, etc., and achieve increased compactness, impermeability, and shrinkage Low, the effect of improving the crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

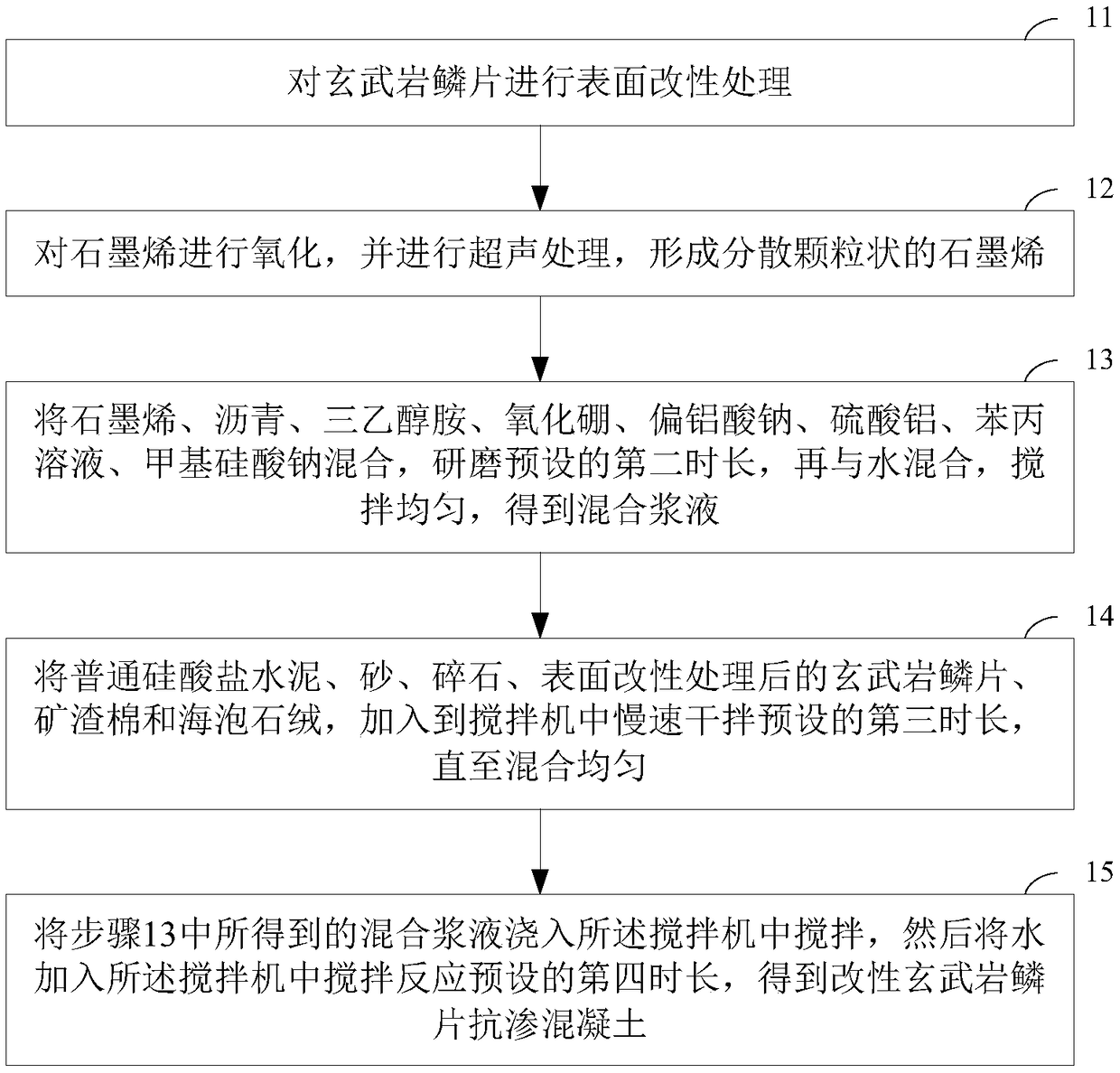

[0033] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] In the technical solution of the present invention, a modified basalt scale impermeable concrete and a preparation method thereof are proposed, so that the impervious performance of the prepared concrete can be improved.

[0035] For example, in a specific embodiment of the present invention, the modified basalt flake impervious concrete includes the following components in parts by mass:

[0036] Ordinary Portland cement 170-200, fly ash 10-50, crushed stone 400-600, sand 300-400, basalt scale 50-70, graphene 0.4-0.6, water reducing agent 1-3, silane coupling agent 1 ~2, slag cotton, sepiolite wool 10~15, asphalt 30~40, triethanolamine 1-2, boron oxide 6~8, sodium metaaluminate 7~10, aluminum sulfate 1~4, styrene-acrylic solution 20~ 30,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com