Rock wool and method for producing and manufacturing rock wool

A technology of rock wool and basalt, applied in the field of rock wool, can solve the problems of not satisfying users, affecting the effect of spinning, affecting the efficiency of melting, and the uniformity of mixing, so as to achieve the effect of ensuring dispersion and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

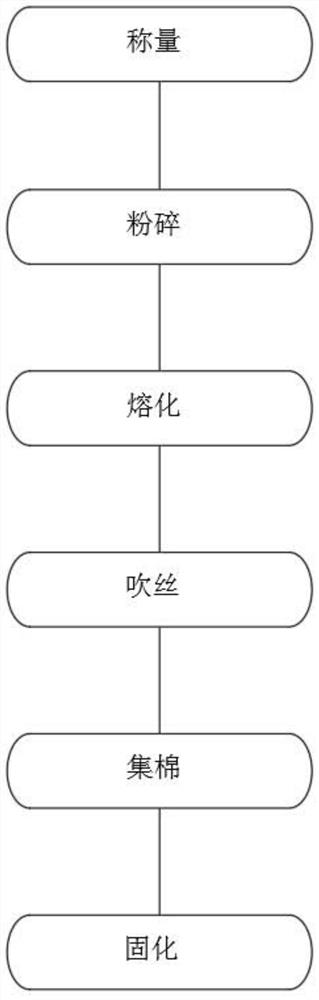

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0032] refer to figure 1 , a kind of rock wool, the rock wool includes the following raw materials by weight: 390 parts of basalt, 60 parts of slag, 70 parts of dolomite, 0.7 part of water-repellent agent and auxiliary materials.

[0033] Accessories include adhesives and anti-dust oil.

[0034] The main components of basalt are silicon dioxide, aluminum oxide, iron oxide, calcium oxide, and magnesium oxide, among which silicon dioxide has the most content, accounting for about 45% to 50%.

[0035] Slag is a by-product of the blast furnace ironmaking process. In the ironmaking process, iron oxide is reduced to metallic iron at high temperature. Impurities such as si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com