Casting sheet mold head automatic control system for polyester optical film

An automatic control system and optical film technology, applied in applications, home appliances, and other home appliances, can solve problems such as low production efficiency, inability to guarantee the quality of film products, and inability to automatically remove dust from die-casting sheets, so as to improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

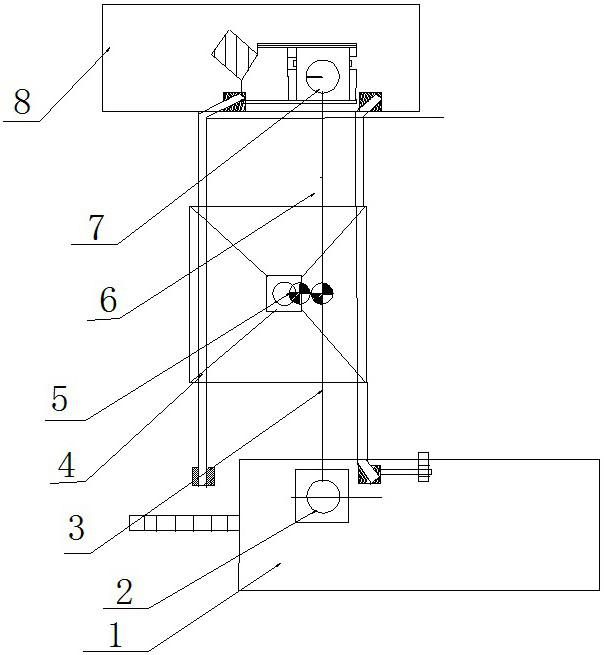

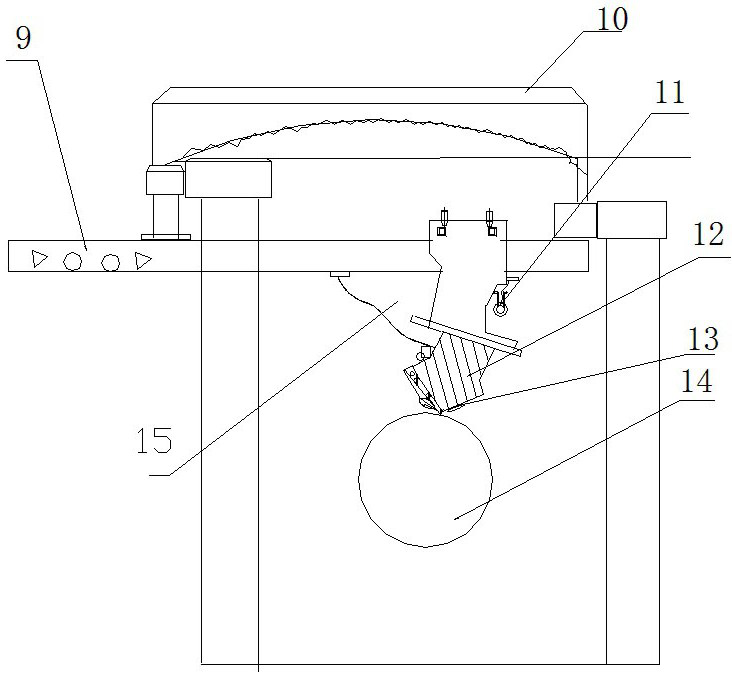

Embodiment 1

[0039] refer to Figure 1-5 , a casting die head automatic control system for polyester optical film, including a main machine system 1 and an auxiliary machine system 8, the main machine system 1 includes a main machine filter 2, a first main machine pipeline 3, a die head exhaust cover 4, and a die lip positioning Point 5, die head 12, die lip 13, cold drum 14, hot wire pipe 15, front die lip heater 16 and die head temperature assembly, auxiliary machine system 8 includes first auxiliary machine pipeline 6, auxiliary machine filter 7, Auxiliary machine system 8, numerical control system 9, dust cover 10, adapter 21, second auxiliary machine pipeline 22, the first main machine pipeline 3 and the first auxiliary machine pipeline 6 are connected through the die lip positioning point 5; the main machine system 1 is connected with the auxiliary machine system 8 through the first main machine pipeline 3, the first auxiliary machine pipeline 6, and the die lip positioning point 5; ...

Embodiment 2

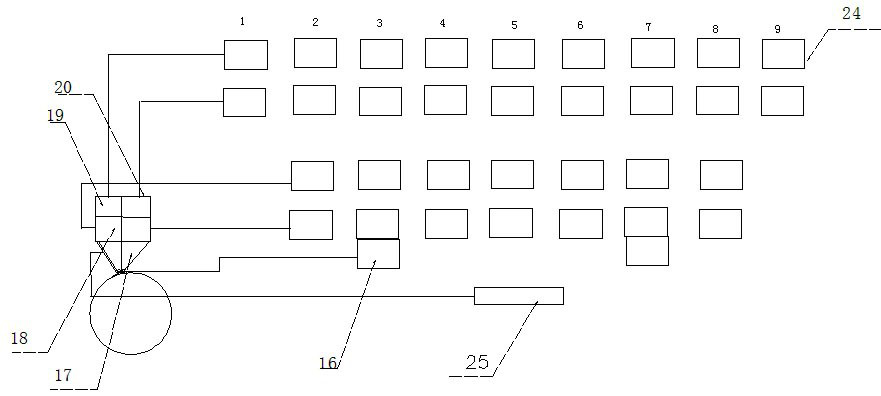

[0048] refer to Figure 1-5 , in the present embodiment, the polyester cast sheet after drying enters die head 12 after entering static mixer again through extruder, pre-filter, metering pump, fine filter, and die head 12 automatically adjusts temperature, and die head is by high The precision die body and the die lip 13 are composed. The die head 12 is divided into four areas in the transverse direction (the first rear front area 17, the lower front area 18, the upper front area 19, and the second rear front area 20). Each area is independently Heating, the temperature of each zone can be independently adjusted and controlled, and the opening of the die lip 13 at each point can be automatically adjusted according to the actual thickness transmitted by the traction station system compared with the target thickness, and each heating unit is equipped with independent air cooling on both sides system to ensure accurate control of the thickness of the cast sheet. When the melt of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com