A continuous strip bamboo strip preparation system and preparation method

A preparation system and technology for bamboo strips, which are applied to the continuous strip-shaped bamboo strip preparation system and the field of preparation, can solve the problems of poor quality uniformity and continuity, bamboo knots or defects, and limited length of bamboo strips, etc., so as to ensure uniform quality. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

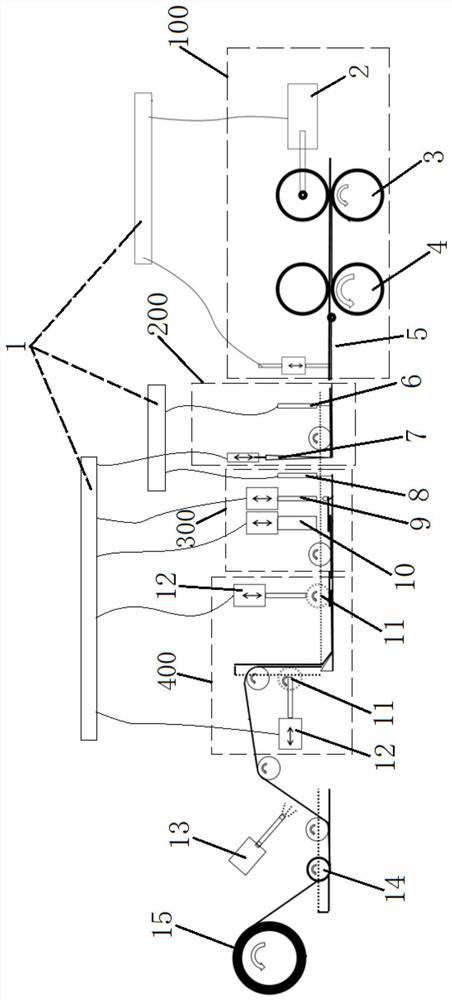

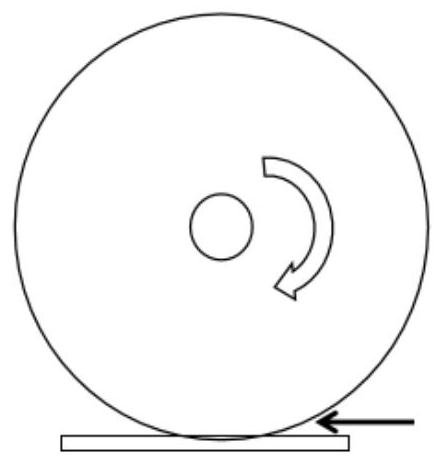

[0038]This embodiment provides a continuous strip-shaped bamboo strip preparation system, including a controller 1, a frame, and a modulus grading device 100, a cutting device 200, a gluing device 300 and a winding device 15 arranged on the frame. The modulus The grading device 100 is used to classify the bamboo strips 16 according to the tensile modulus, and screen out the bamboo strips 16 that meet the standard. Specifically, the tensile modulus standard of the bamboo strips 16 is determined according to the application scenario of the bamboo strips 16; The cutting device 200 is used for cutting the ends and tails of the bamboo strips 16 that meet the standard; the gluing device 300 is used for gluing the tails and ends of the cut adjacent bamboo strips 16 to form a continuous strip of bamboo strips; The device 15 is used for winding the continuous strip bamboo strips, and the controller 1 is electrically connected with the modulus grading device 100 , the cutting device 200 ...

Embodiment 2

[0048] This embodiment provides a continuous strip-shaped bamboo strip preparation system, and the difference from Embodiment 1 is: Figure 8-Figure 9 As shown, the mechanical sensor 2 is set below the position where the gap between the first differential wheel and the first differential wheel is fed, and a bamboo strip 16 passes through the gap between the first feed wheel 3 and the second feed wheel 4 in turn. When there is a gap, the mechanical sensor 2 will push down the bamboo strips 16. The mechanical sensor is used to monitor the pressure (F1) on the bamboo strips 16. The controller 1 is electrically connected to the mechanical sensor 2 to convert the tensile force (F1) into Tensile force (F) and tensile modulus, compare the tensile modulus with the standard tensile modulus, the controller 1 is electrically connected to the grading valve 5 to control the opening and closing of the grading valve 5, when the tensile modulus is in the When the standard tensile modulus is w...

Embodiment 3

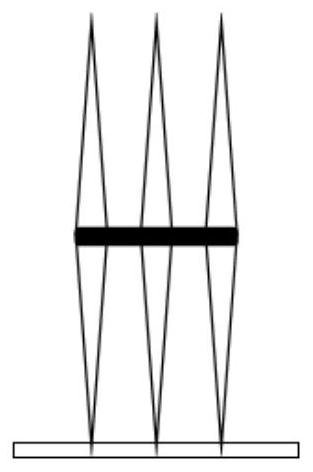

[0050] This embodiment provides a continuous strip-shaped bamboo strip preparation system, and the difference from Embodiment 1 is: Figure 10 The shown gluing device 300 includes a second sensor 8, a laminating machine and a pressing device 10, and the second sensor 8, the laminating machine and the pressing device 10 are all electrically connected to the controller 1; when the second sensor 8 monitors the adjacent When the tails and ends of the bamboo strips 16 are opposite, the controller 1 receives the signal from the second sensor 8 to control the laminating machine to coat the tails and ends of the adjacent bamboo strips 16. The film-coated positions of the tail and end of the bamboo strips 16 are pressed together to form a continuous strip of bamboo strips.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com