Patents

Literature

75 results about "Plastic magnet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A plastic magnet is a non-metallic magnet made from an organic polymer. One example is PANiCNQ, which is a combination of emeraldine-based polyaniline (PANi) and tetracyanoquinodimethane (TCNQ). When it was created by Pakistan born scientist Naveed A. Zaidi and colleagues at the University of Durham in 2004, it was the first magnetic polymer to function at room temperature.

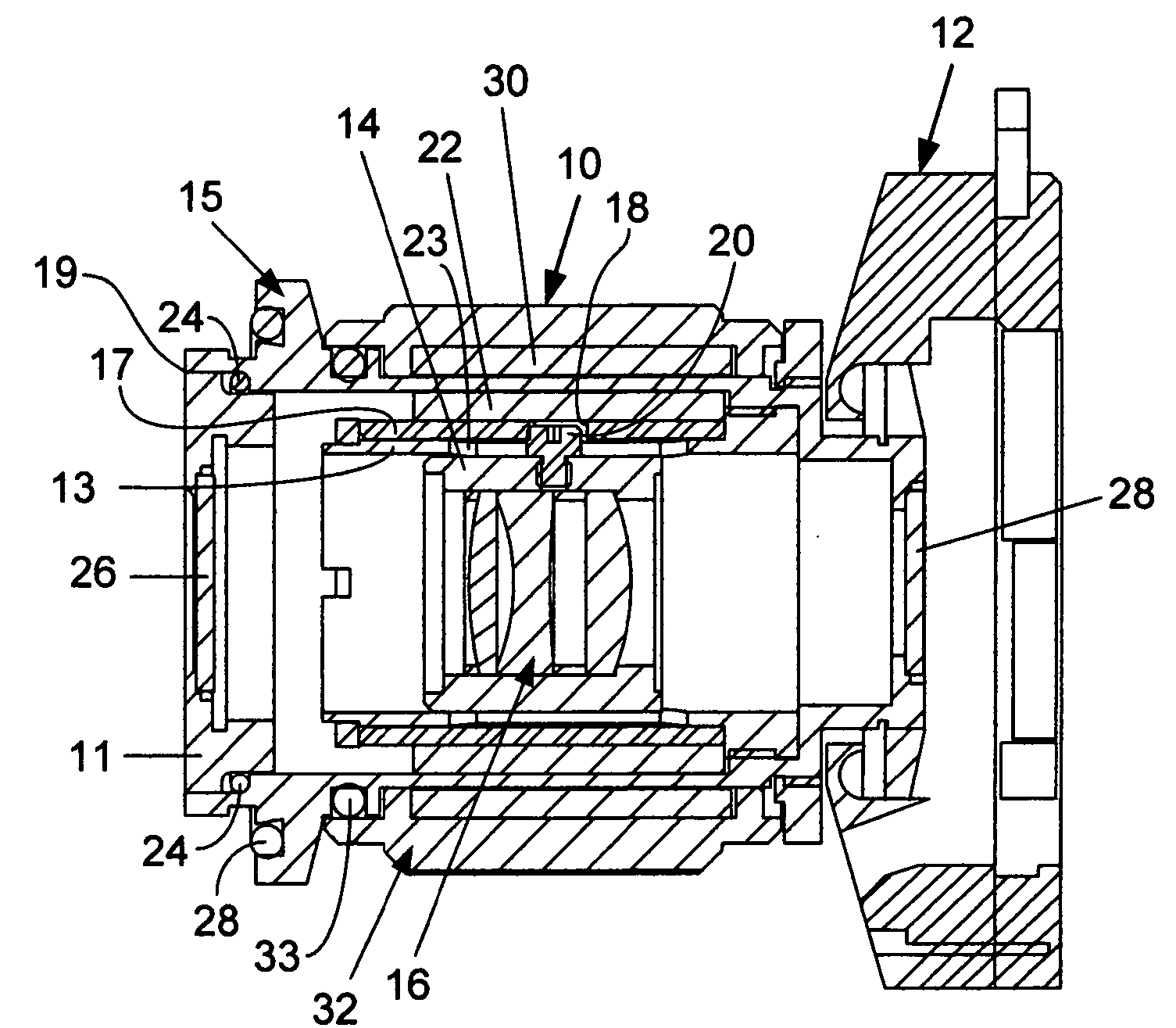

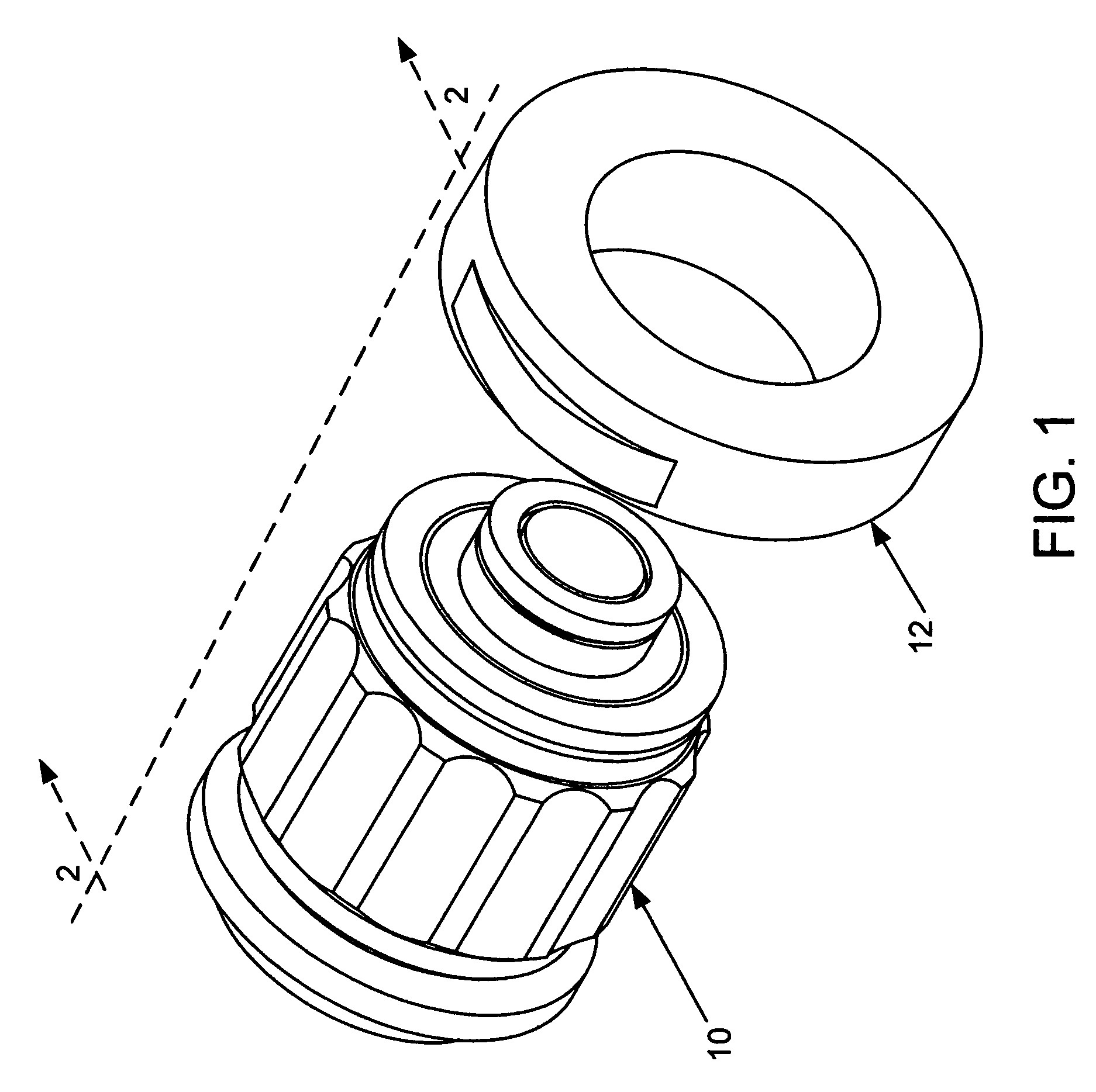

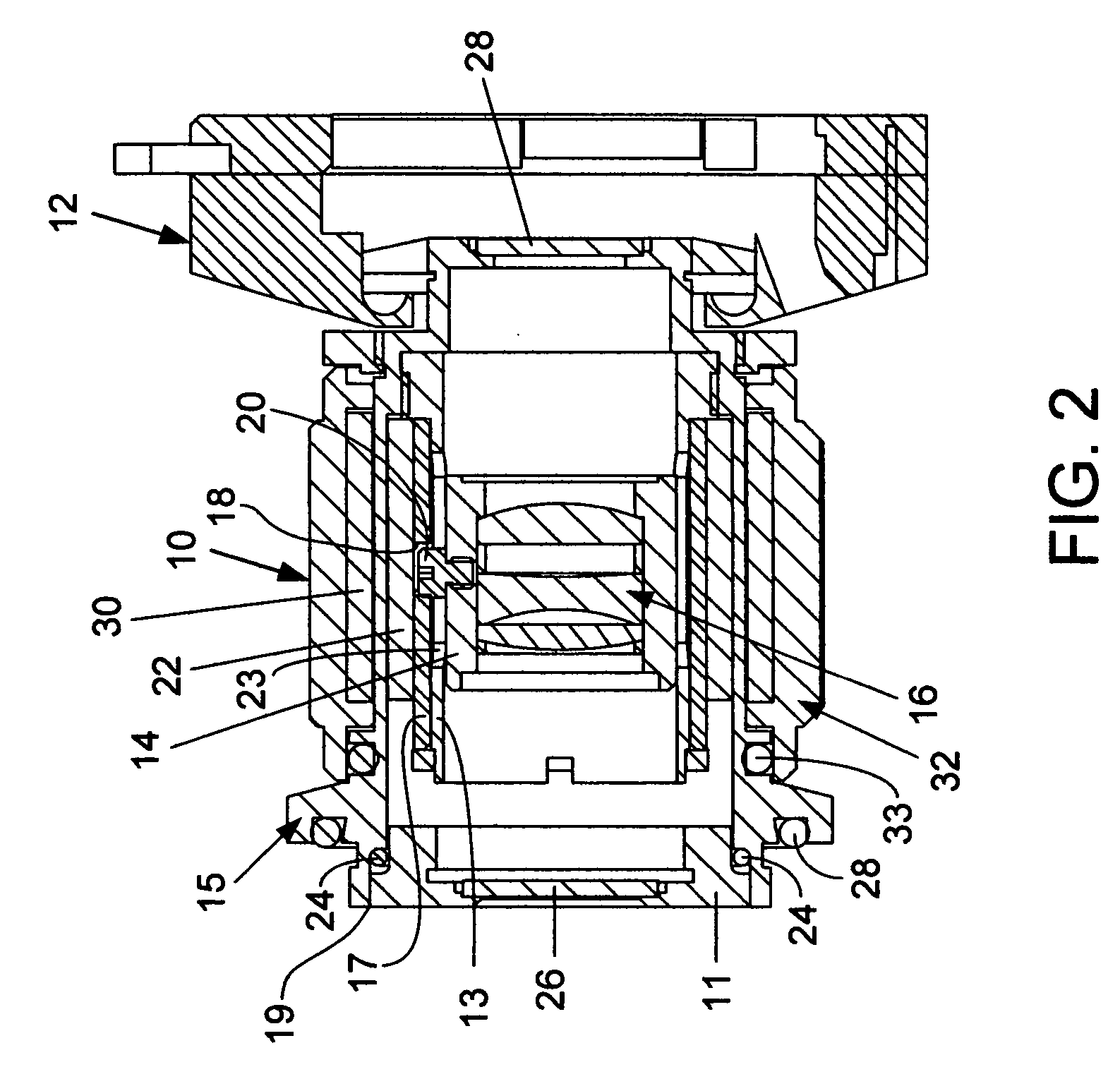

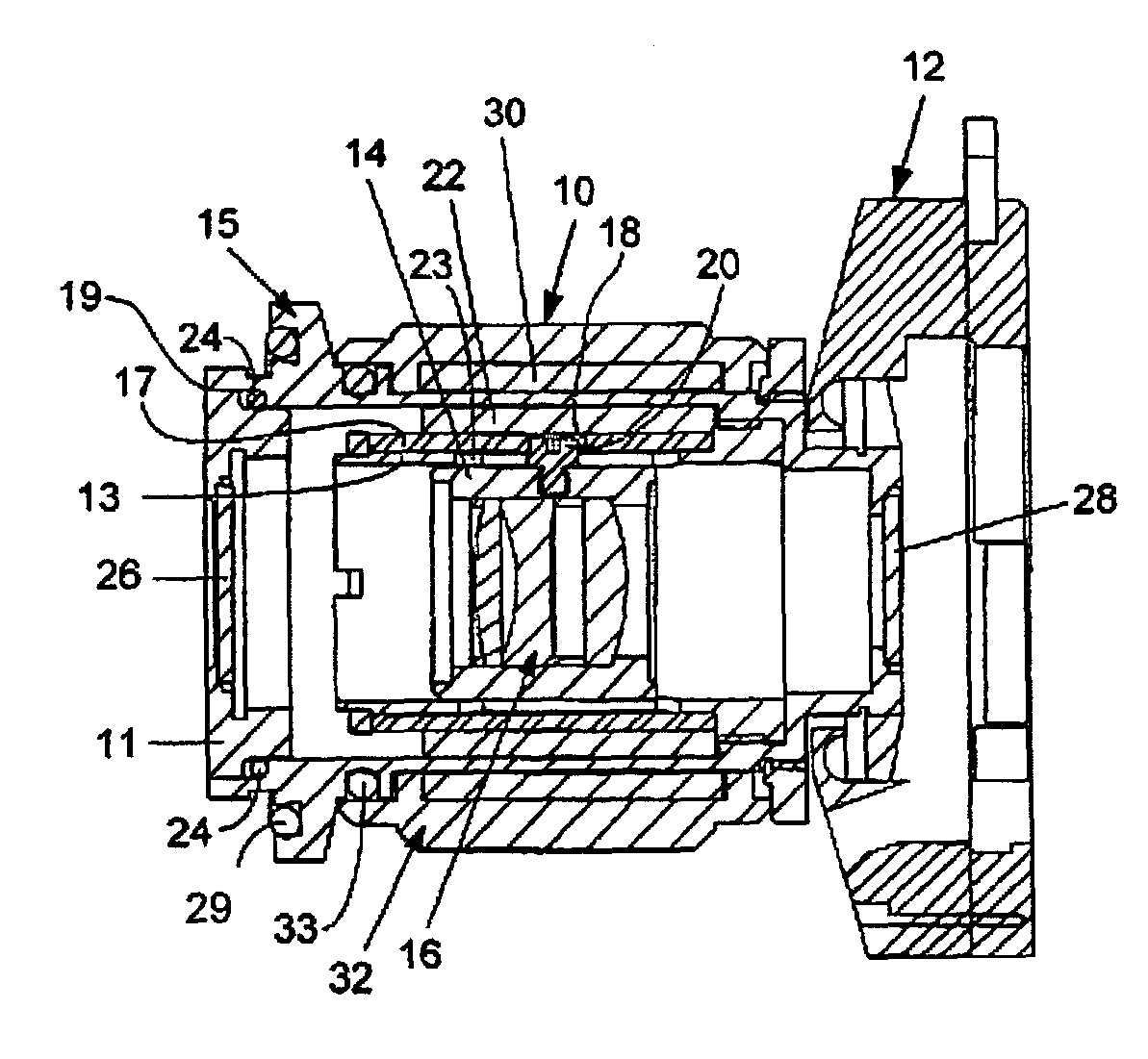

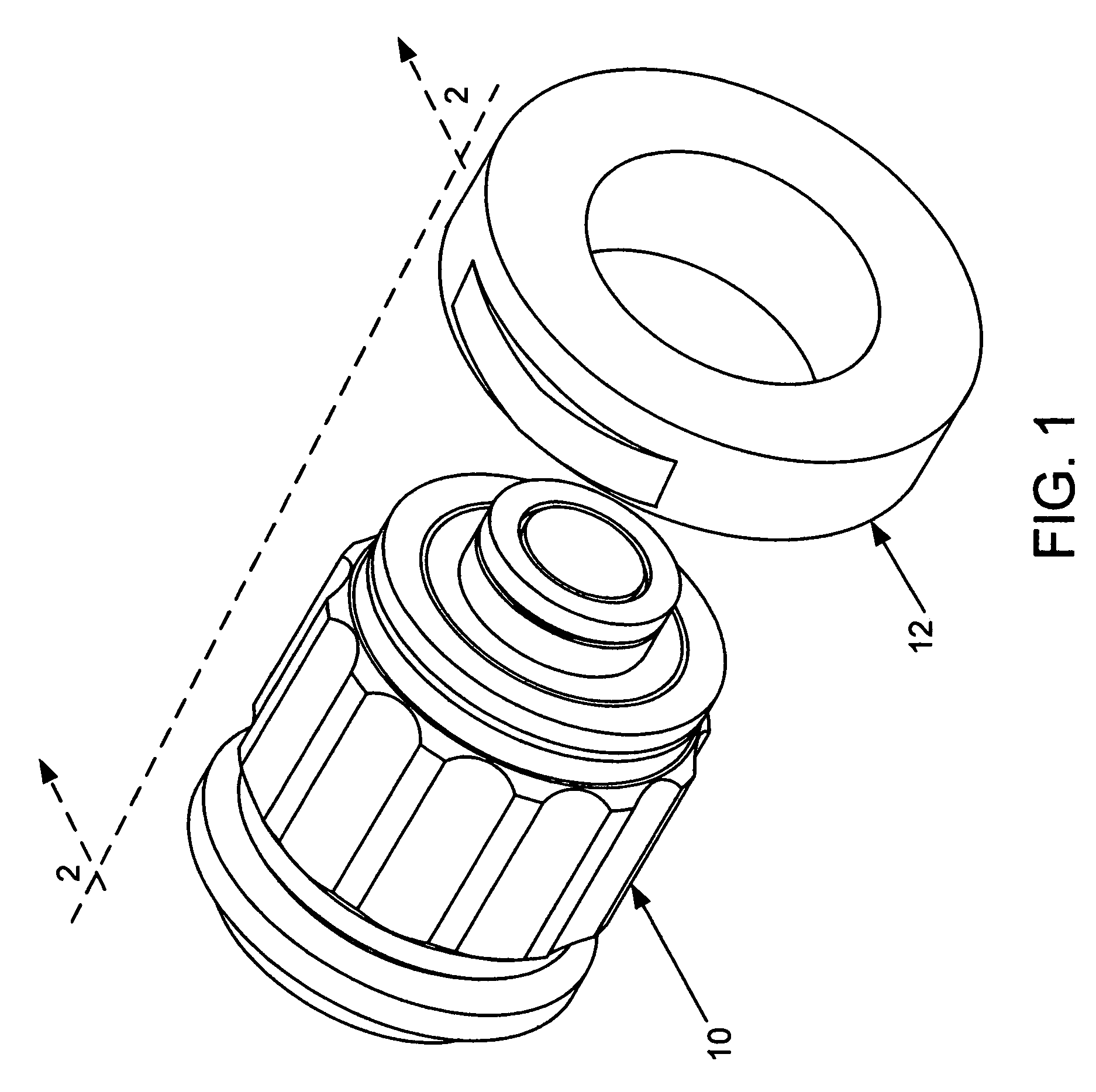

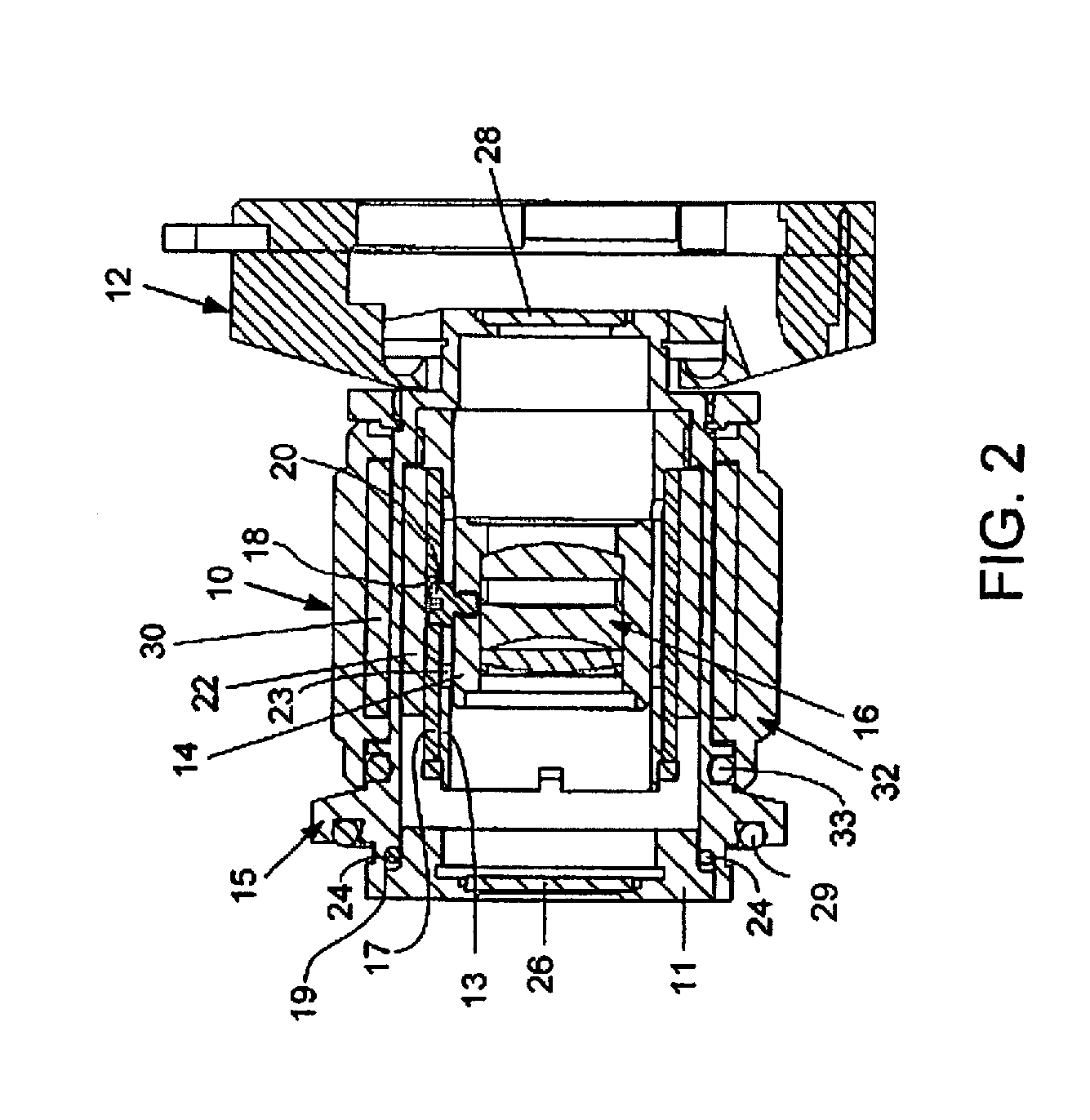

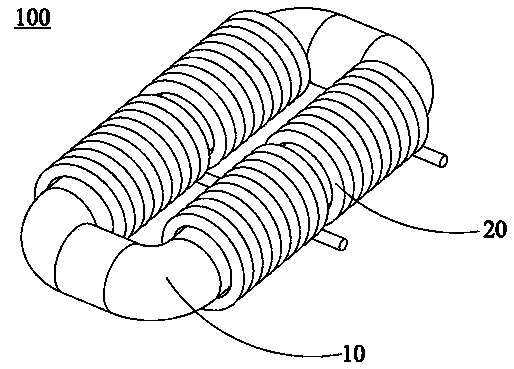

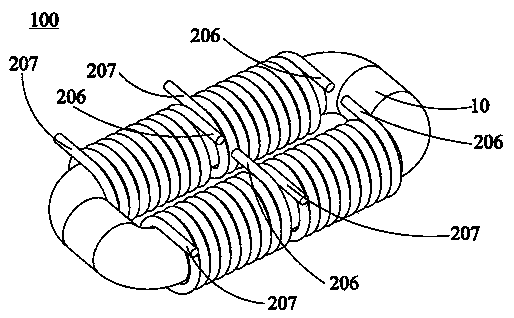

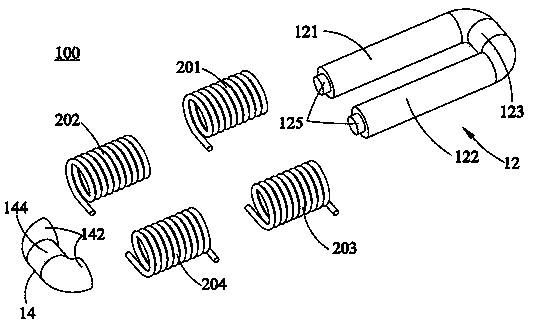

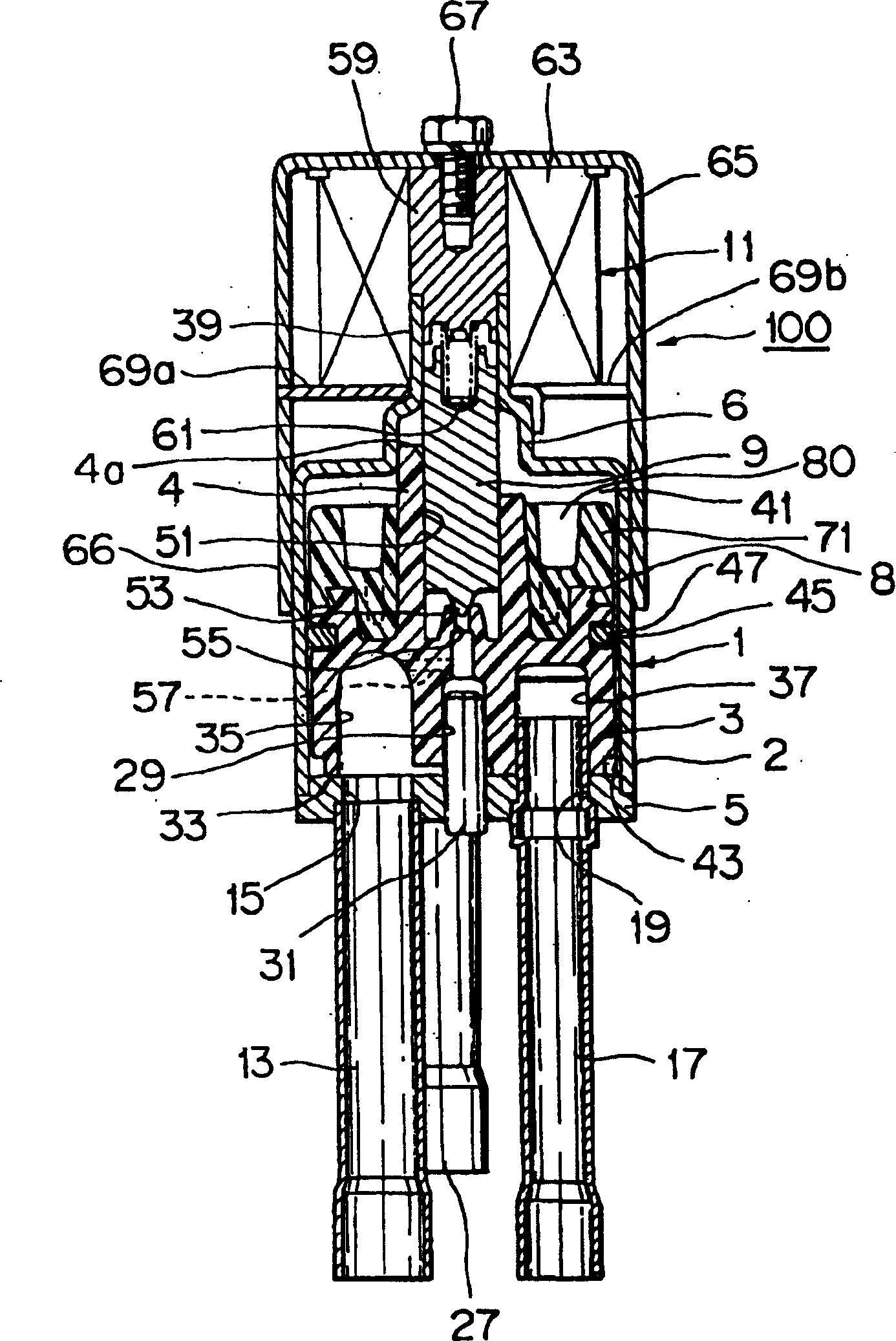

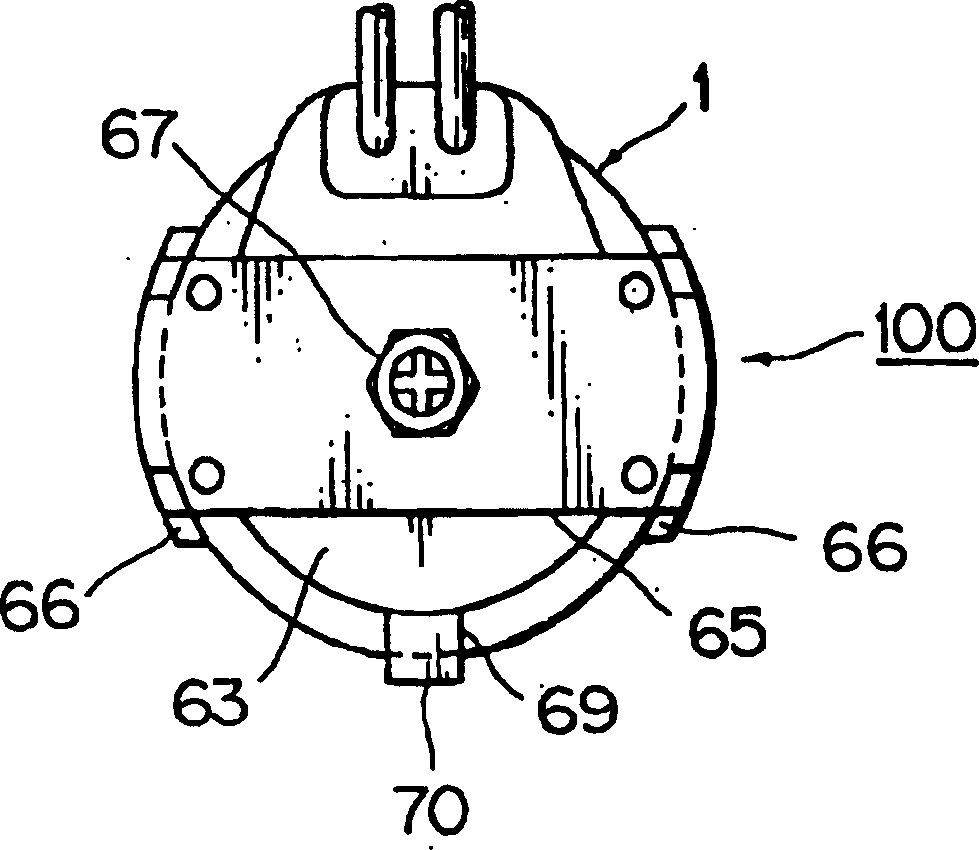

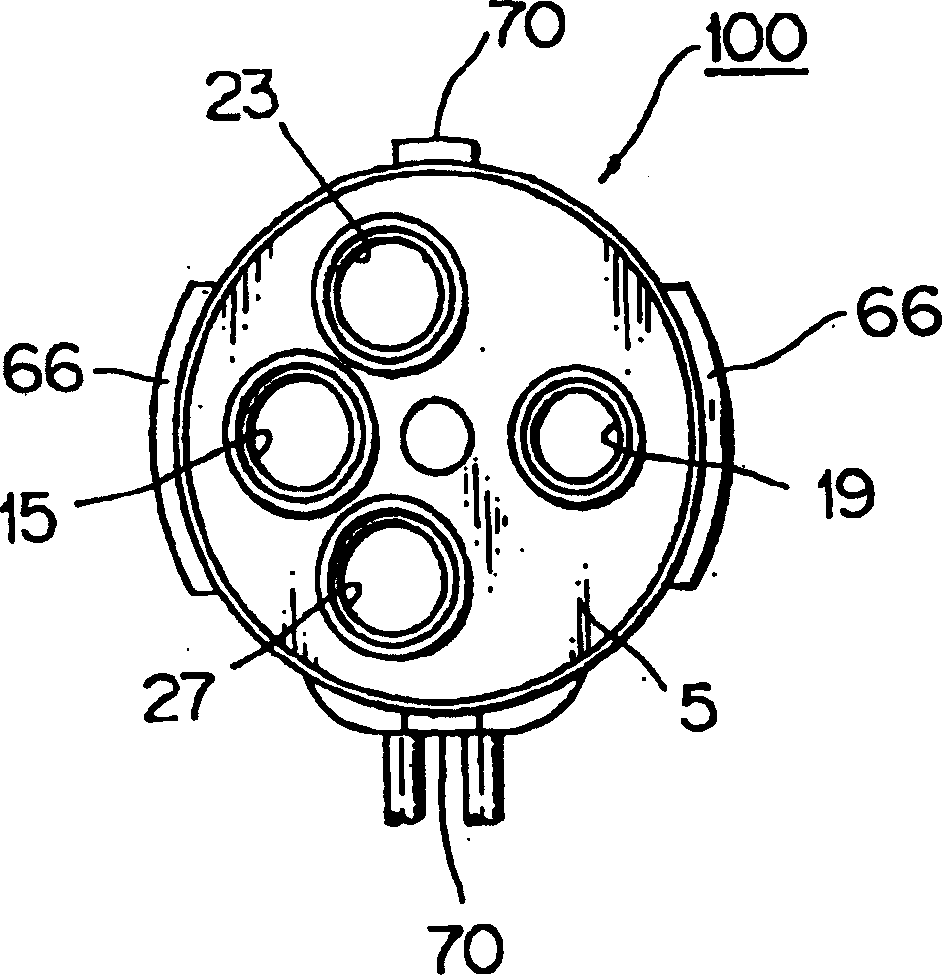

Magnetically actuated endoscope coupler

An endoscopic coupler by which the rotary and / or linear motion of an external ring is transferred via magnetic interaction of specially configured continuous plastic magnets to a lens resident in a hermetically sealed housing to effect focusing and / or zooming action of the lens without mechanically breaching the integrity of the hermetic seal thereby making the coupler particularly suitable for withstanding the rigors of autoclaving.

Owner:LIGHTHOUSE IMAGING

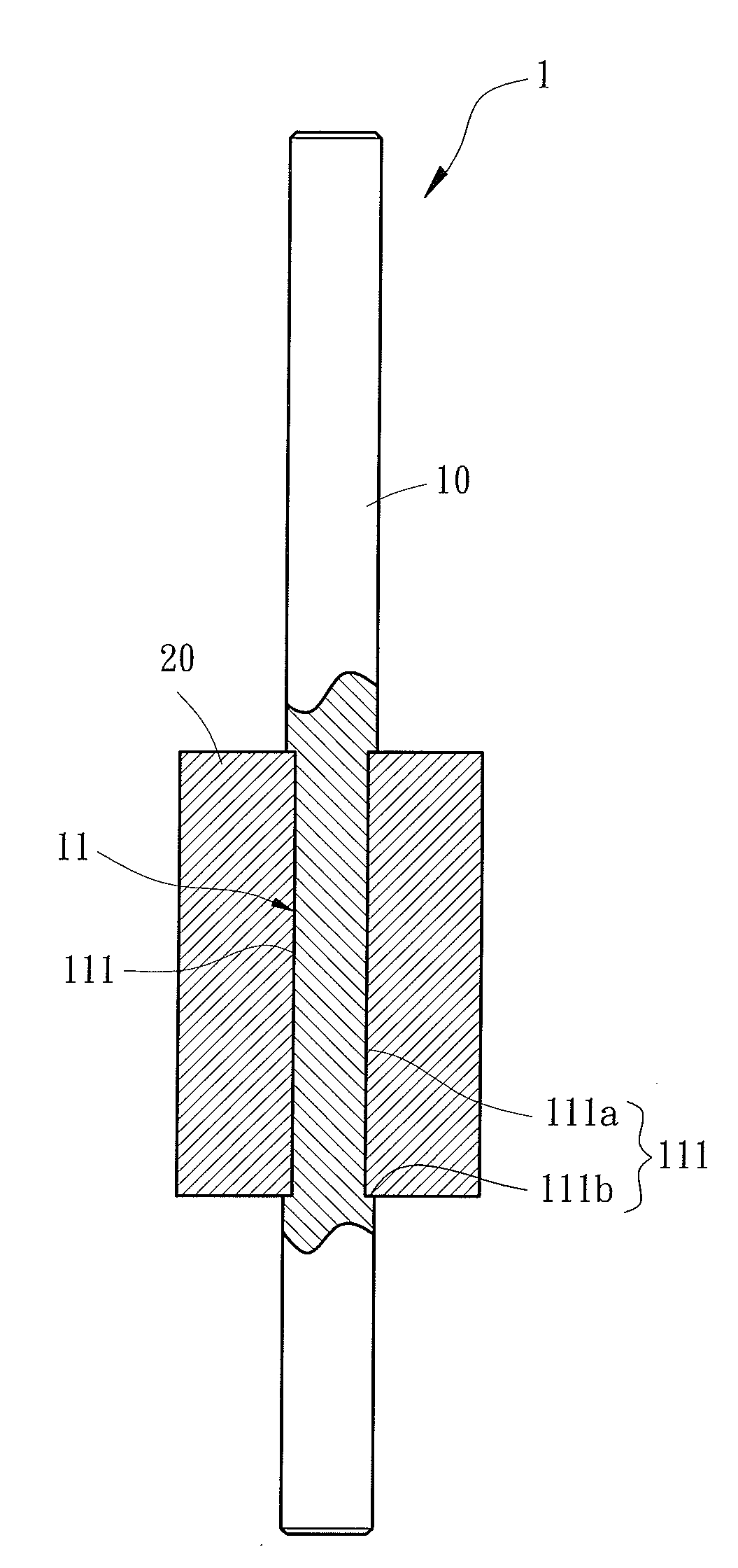

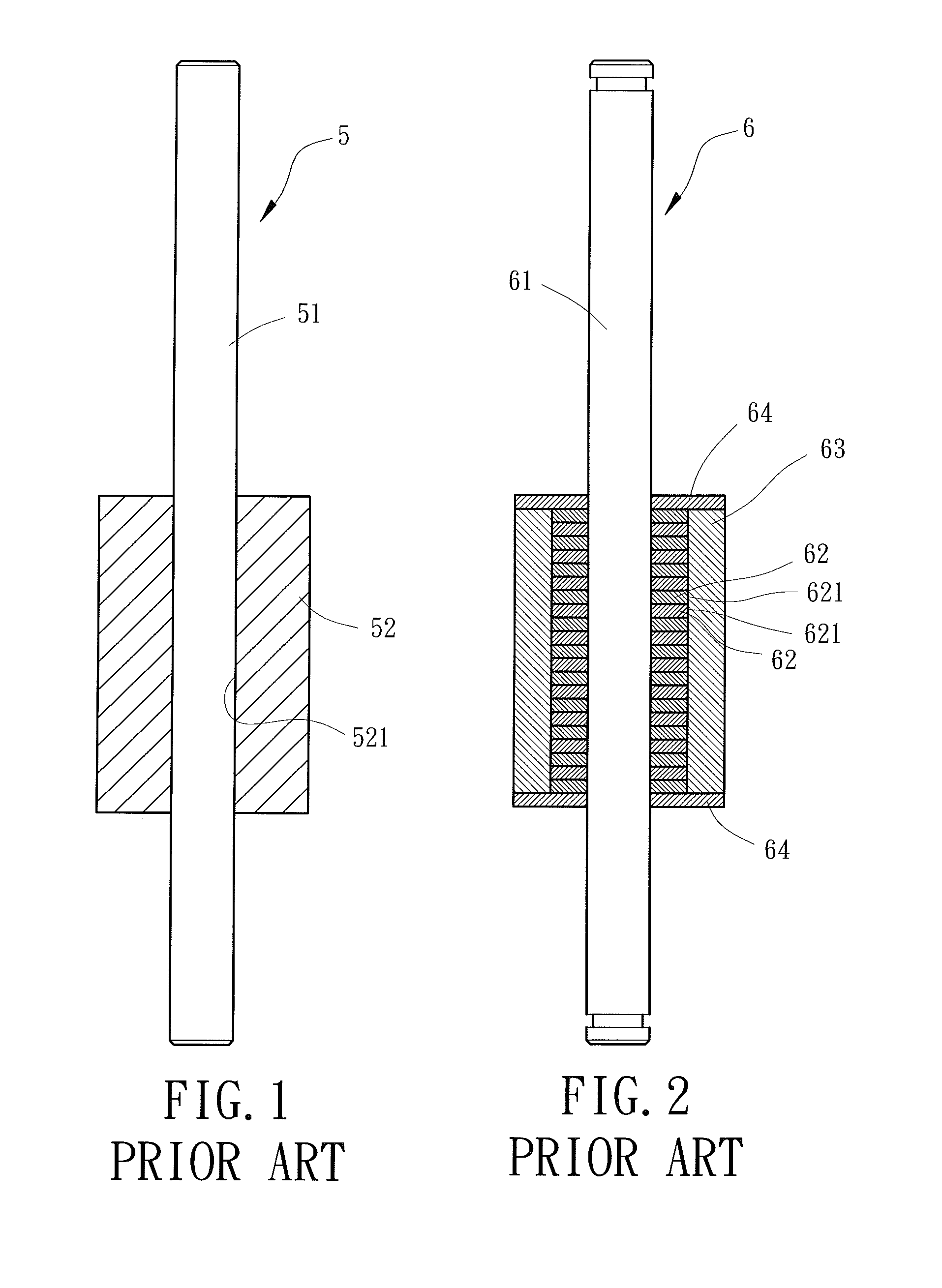

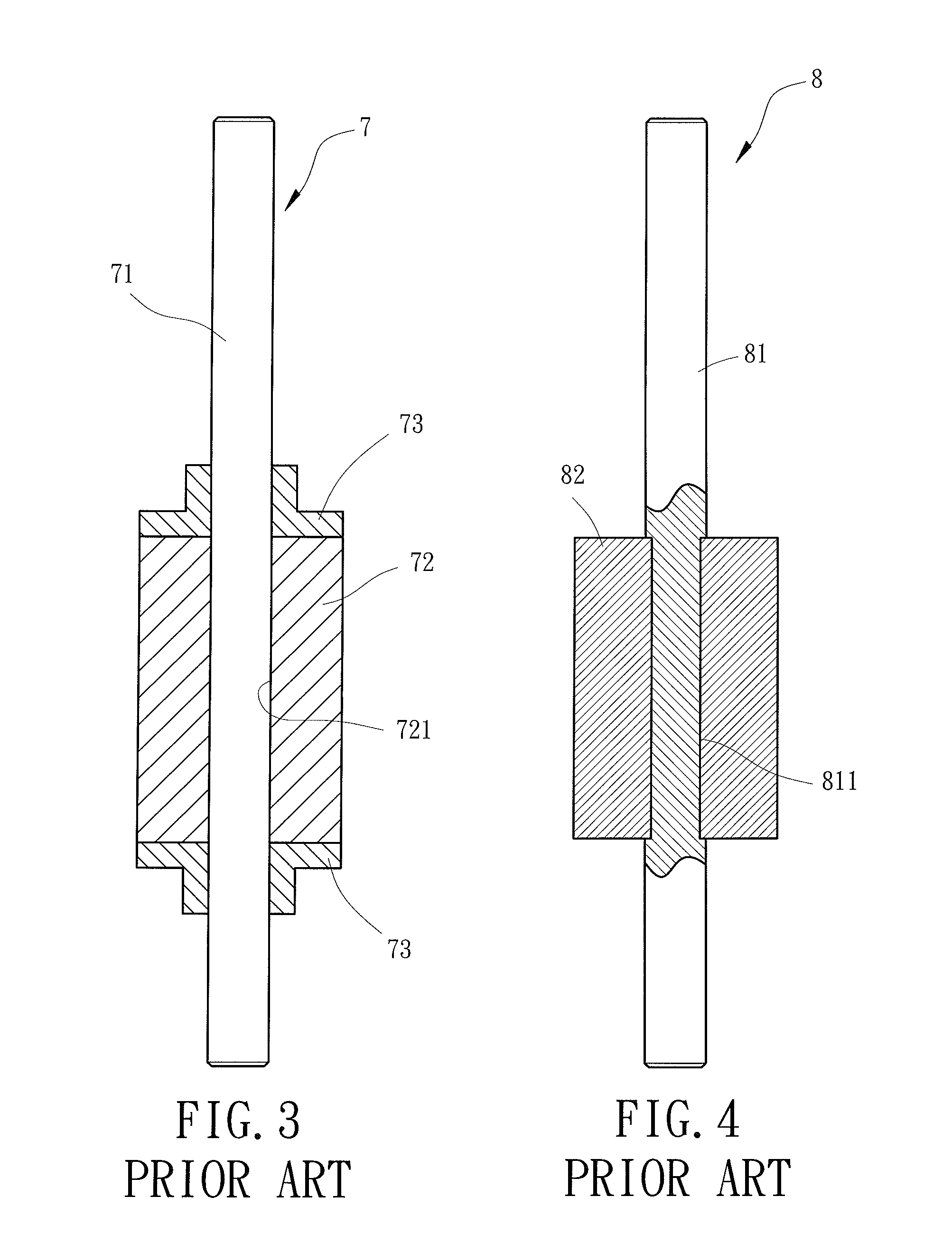

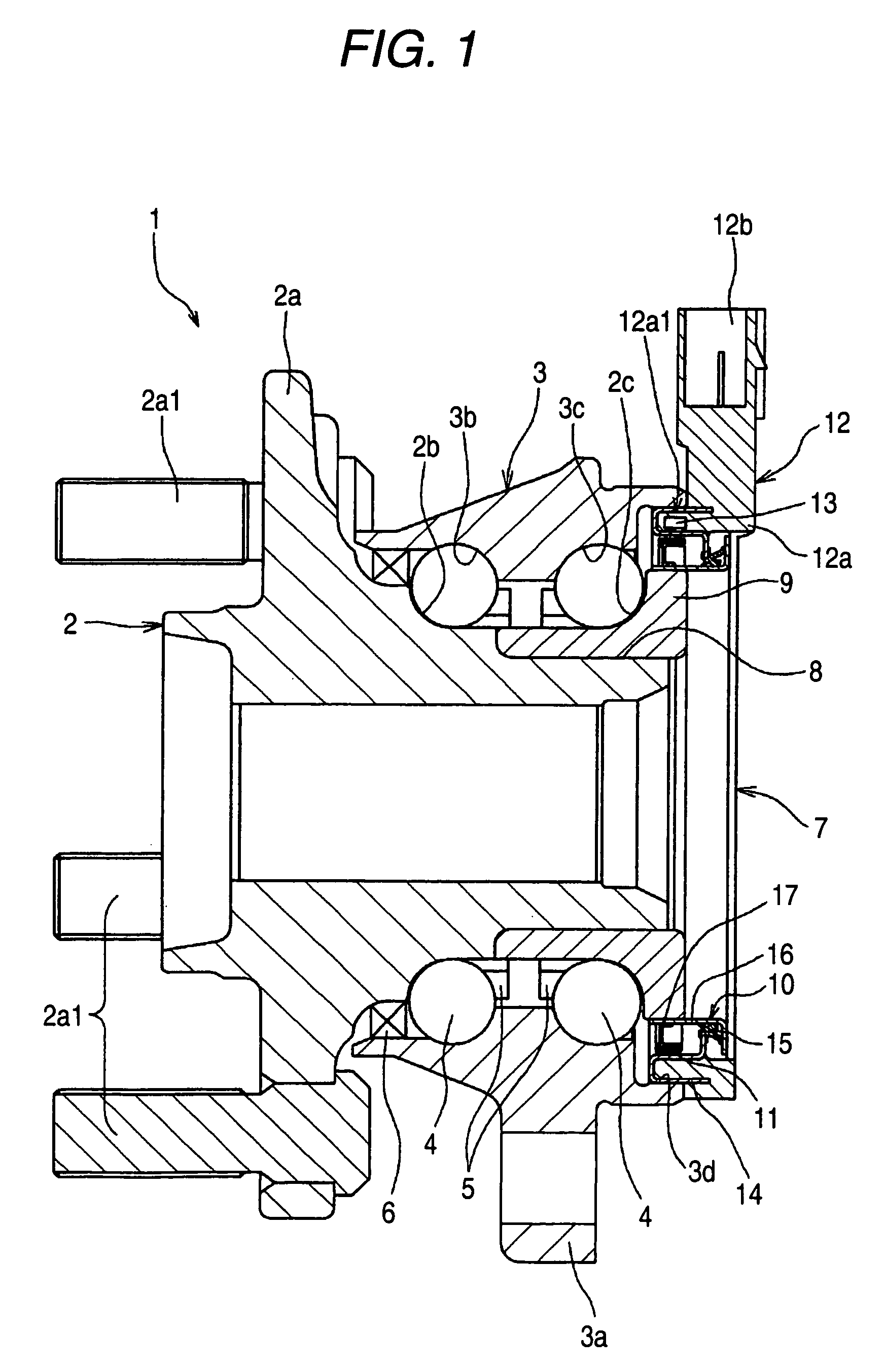

Rotor for Motor

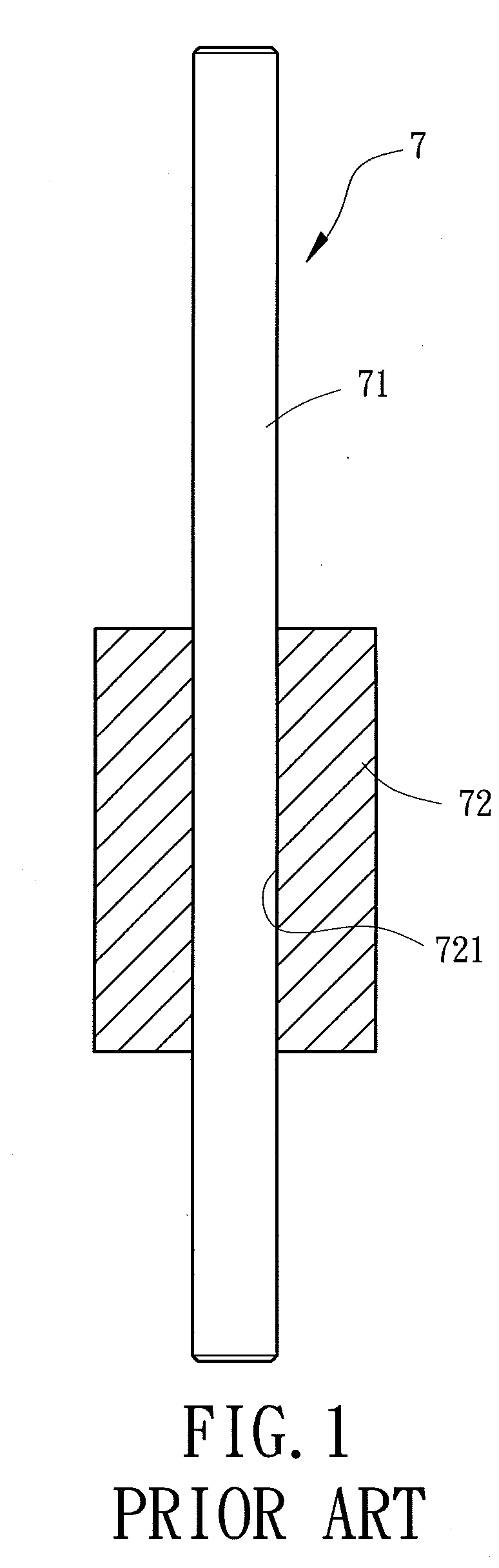

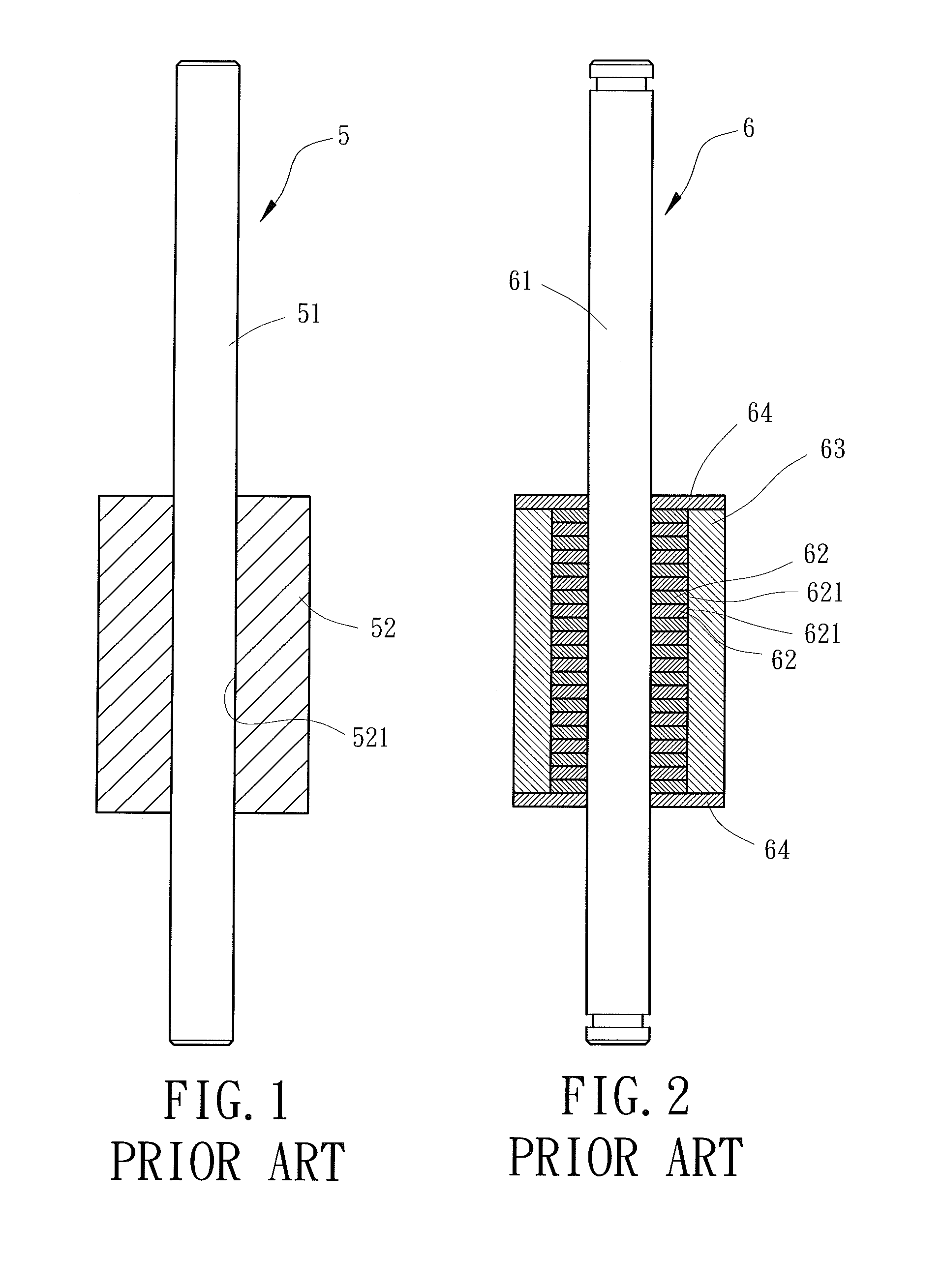

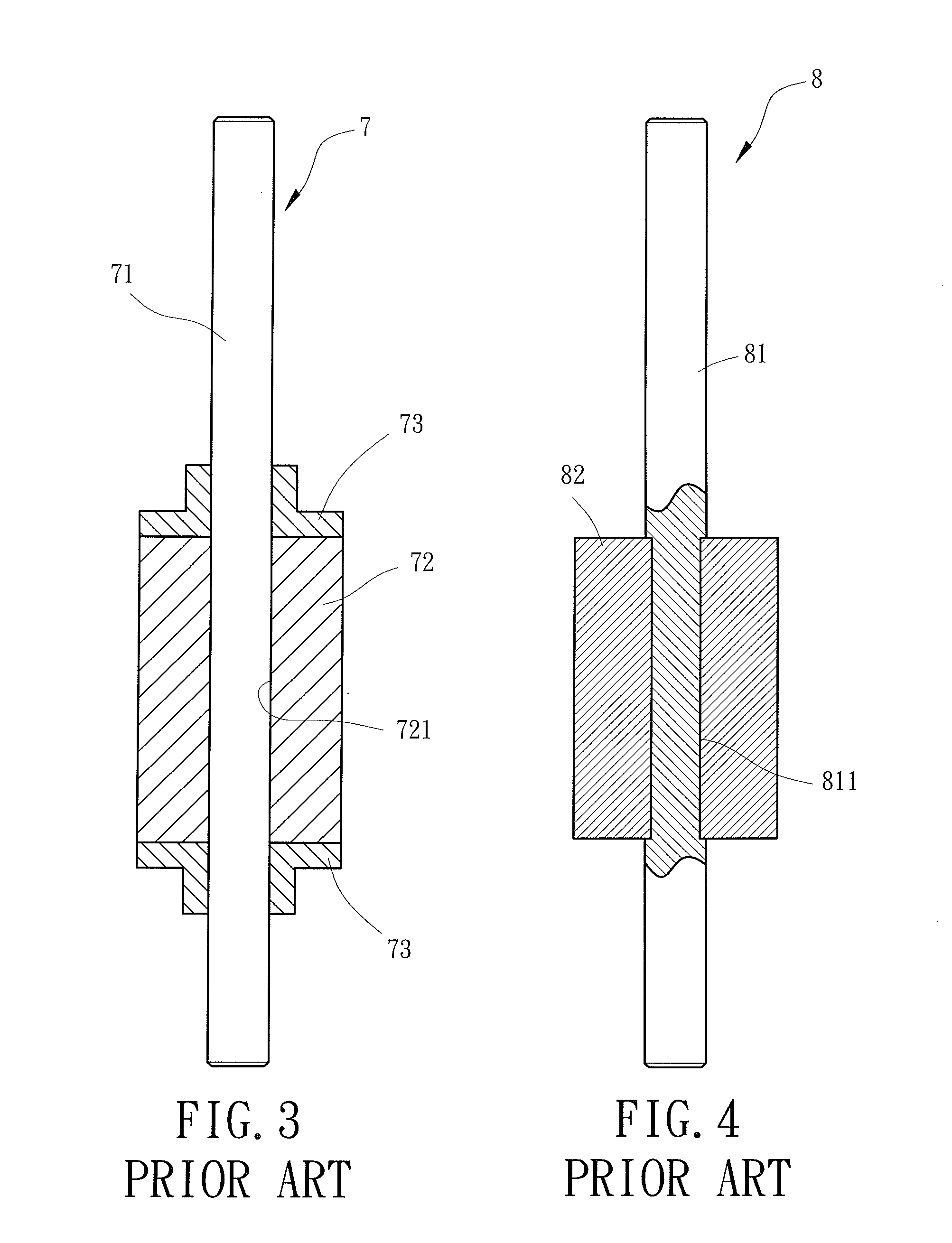

InactiveUS20100066189A1Simple structureImprove participationMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsElectric machineEngineering

A rotor for a motor includes a shaft having an outer periphery with a positioning portion. The positioning portion has non-circular cross sections perpendicular to a longitudinal axis of the shaft. A plastic magnet is formed on the outer periphery of the shaft by injection molding. The plastic magnet includes an inner periphery engaged with the positioning portion. Thus, the plastic magnet is prevented from disengaging from the shaft and from rotating relative to the shaft. As a result, the rotor has enhanced engaging effect between the shaft and the plastic magnet. Furthermore, the rotor has a simple structure to allow easy assembly.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

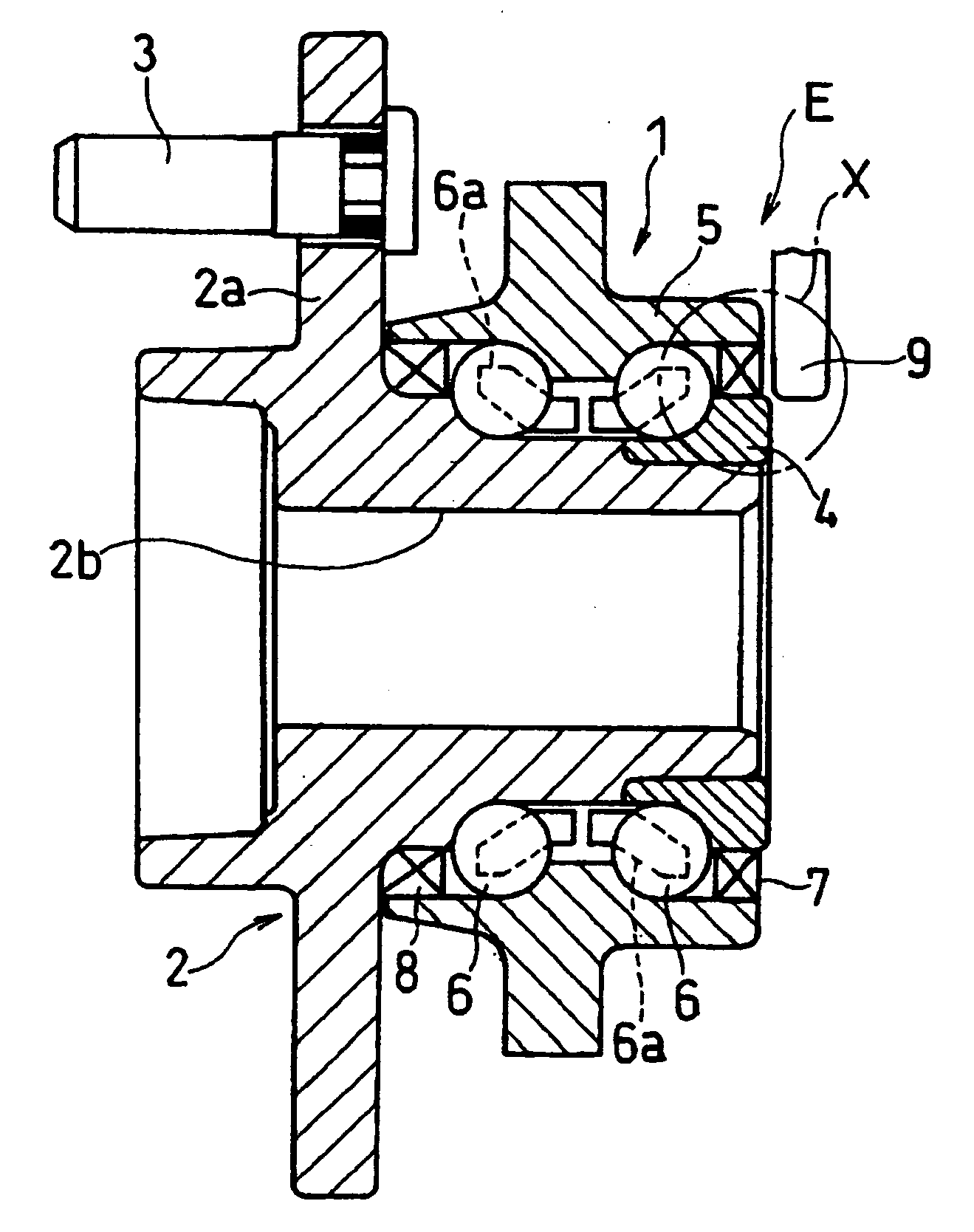

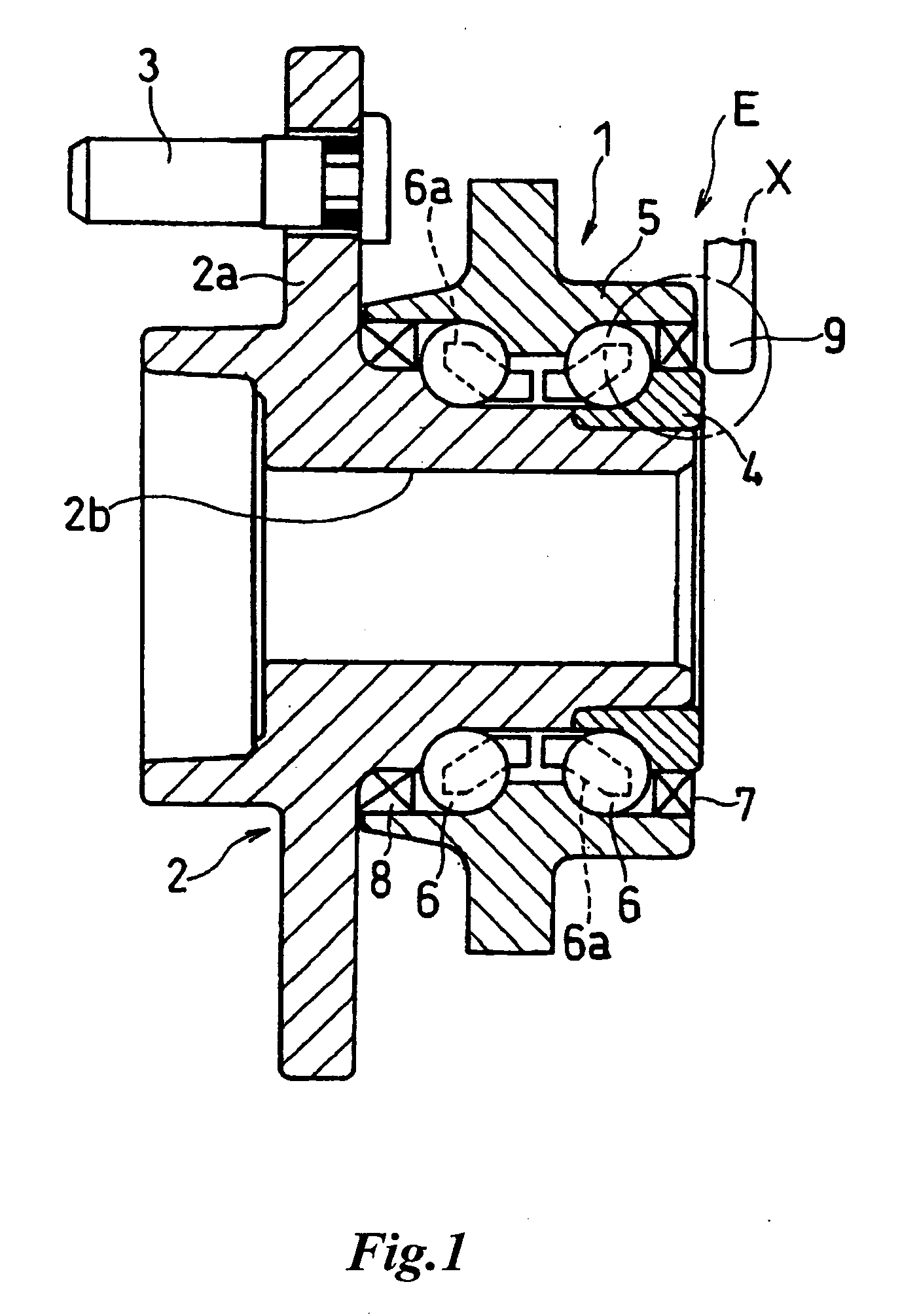

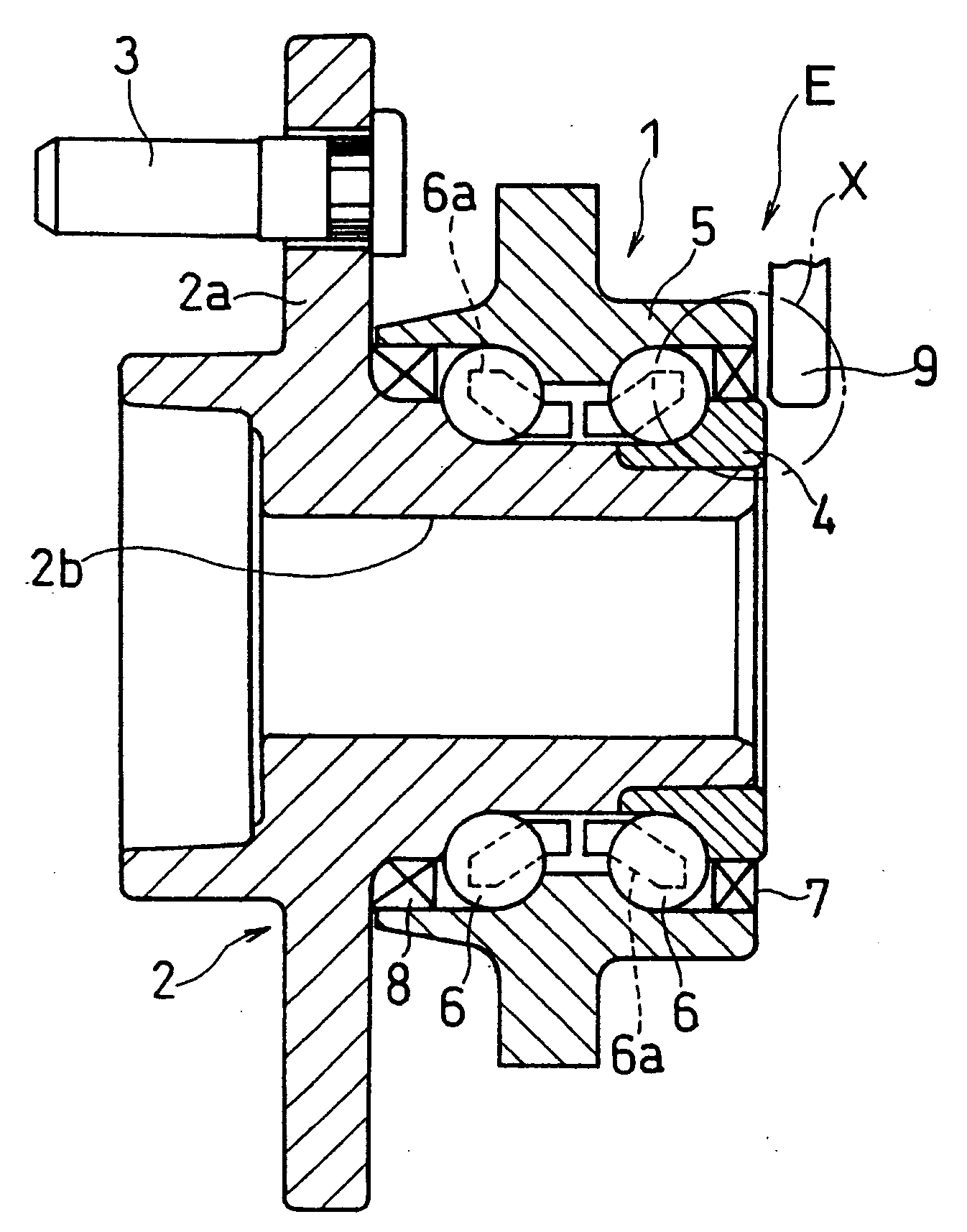

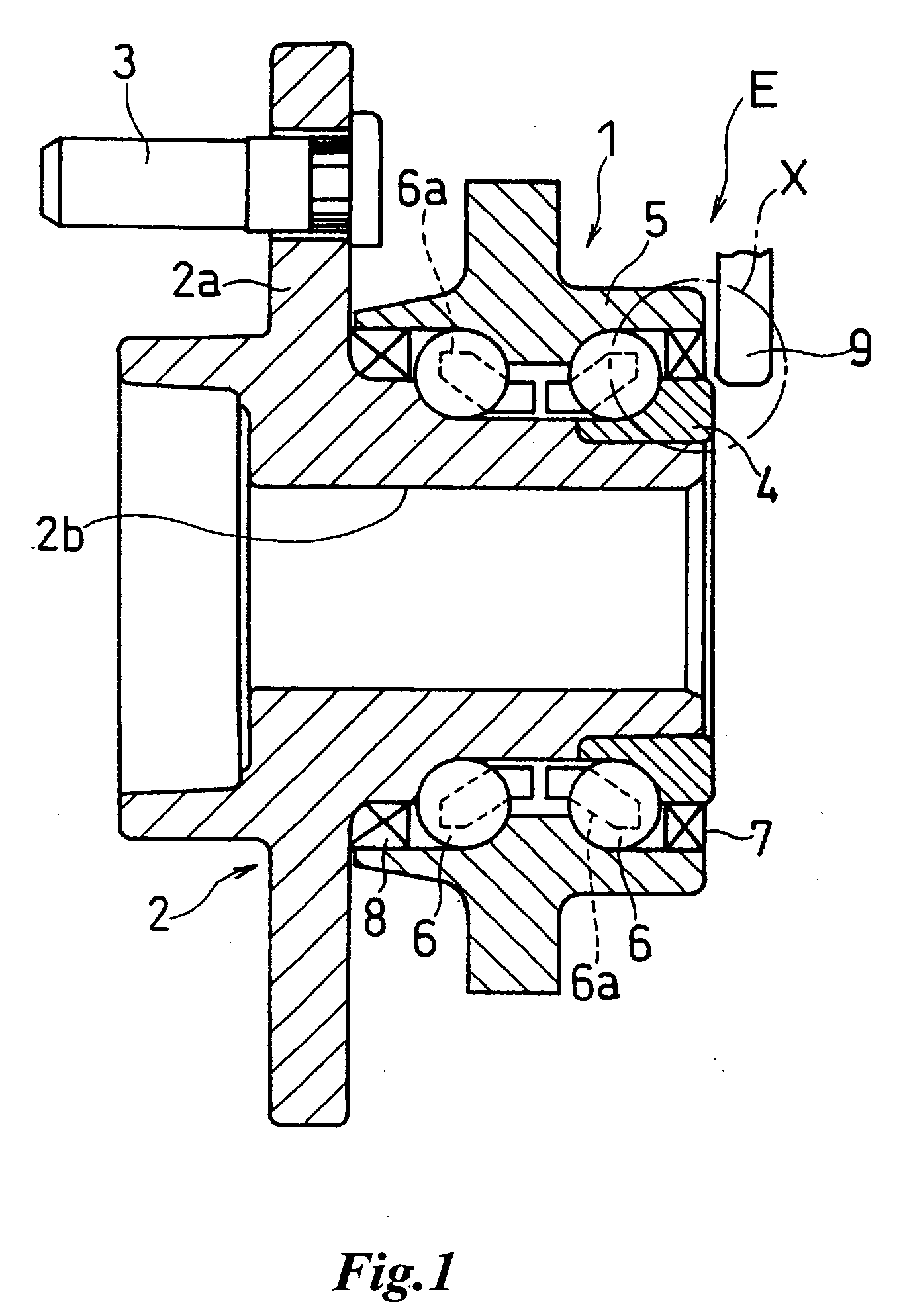

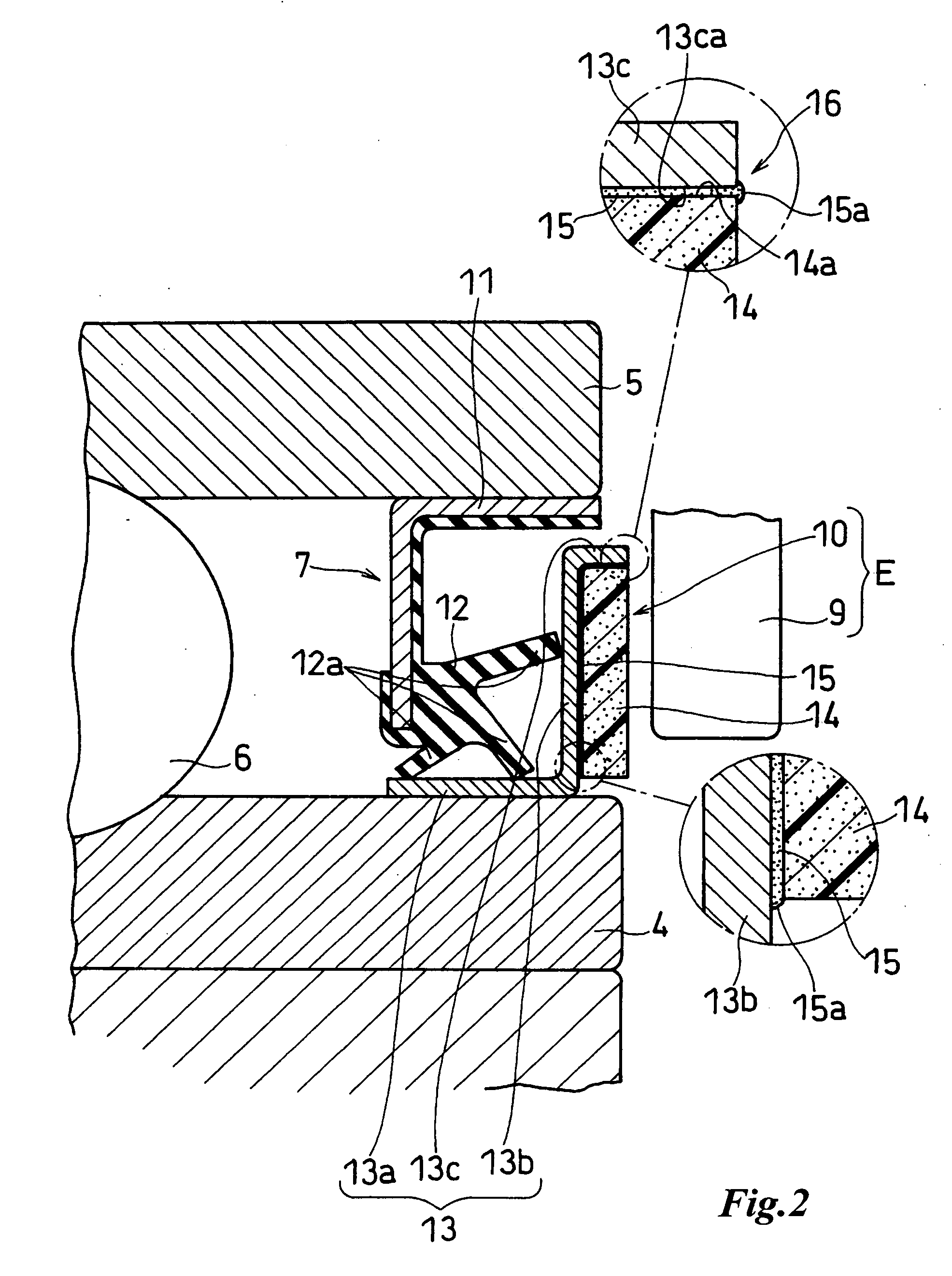

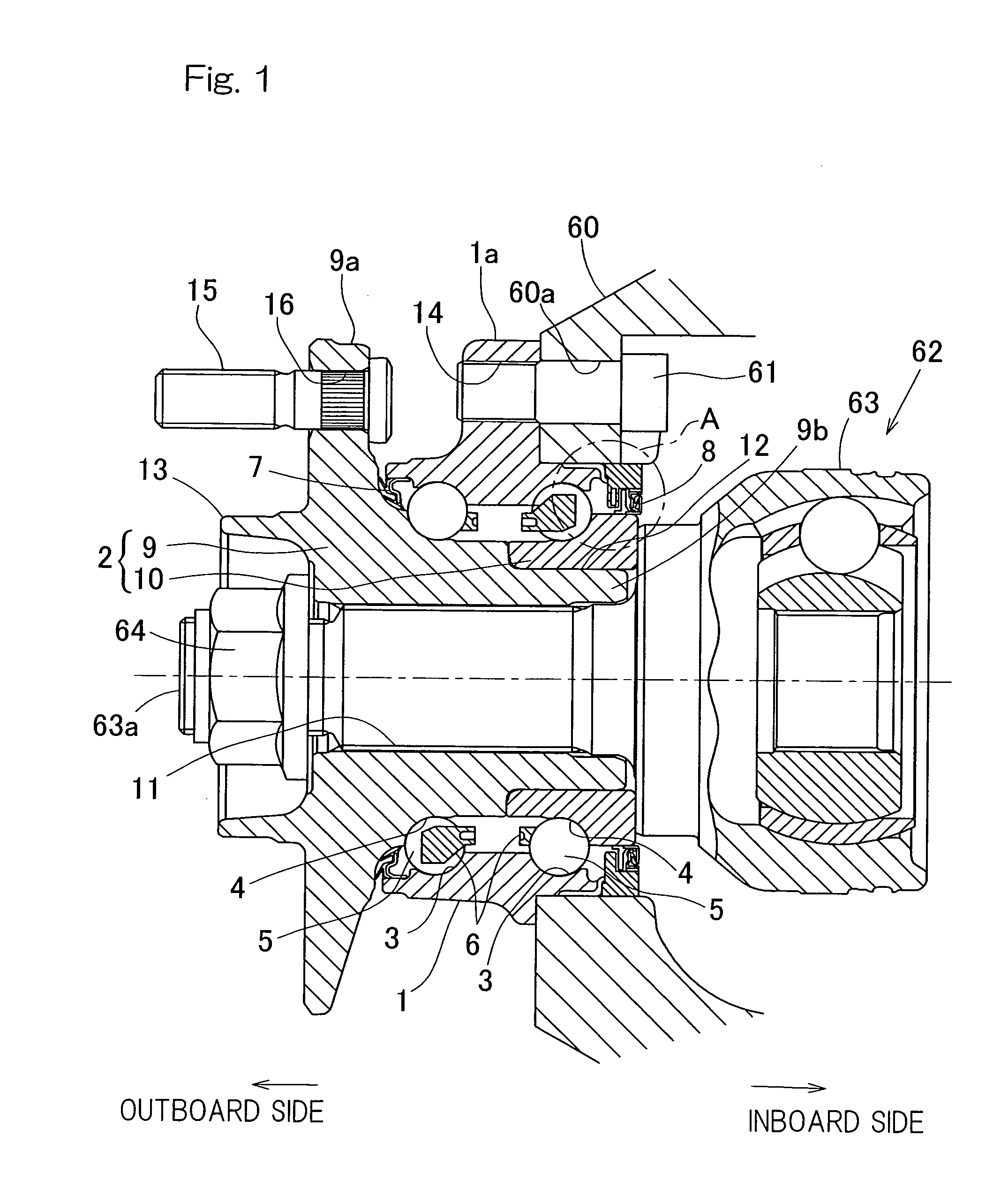

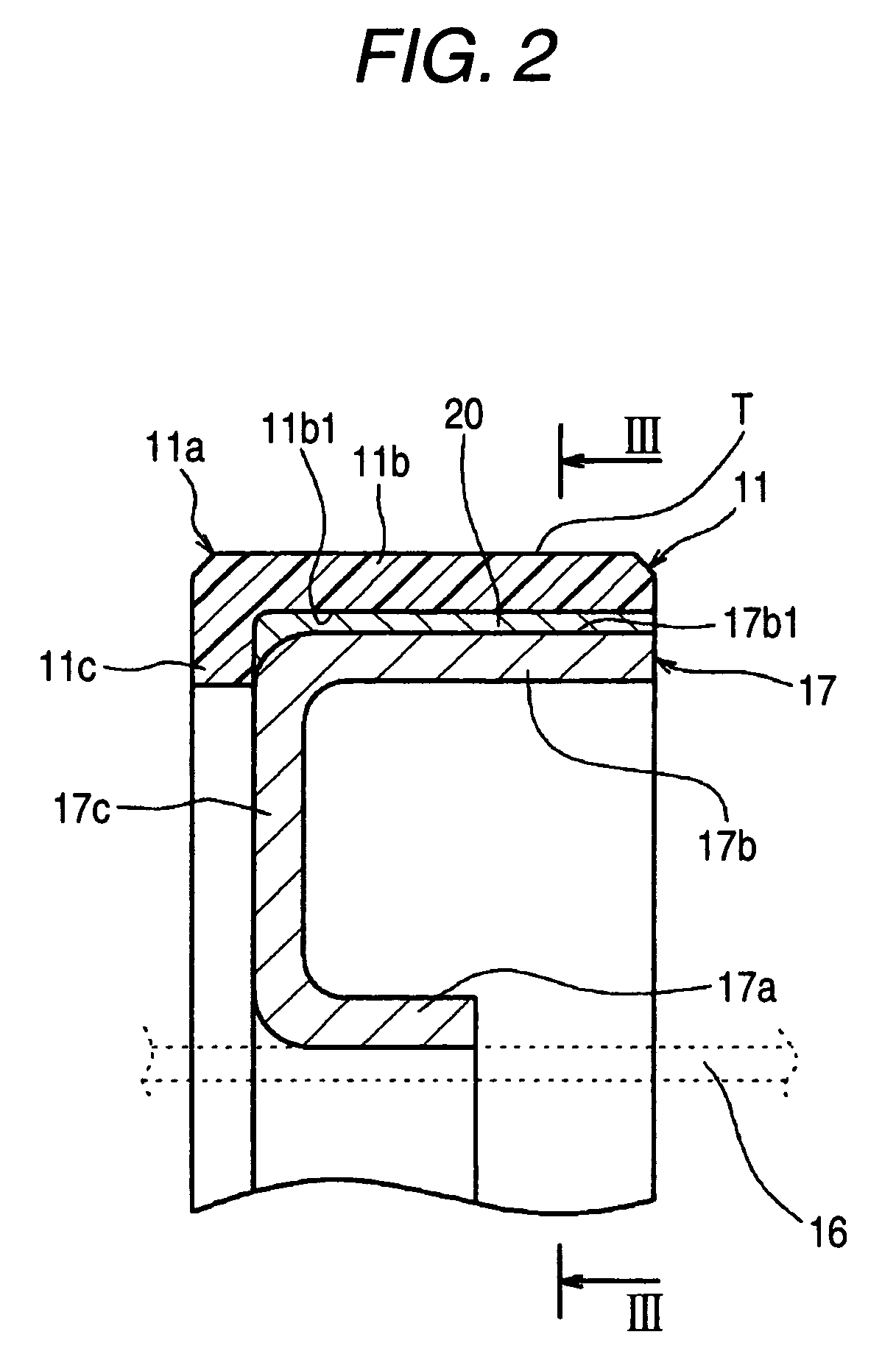

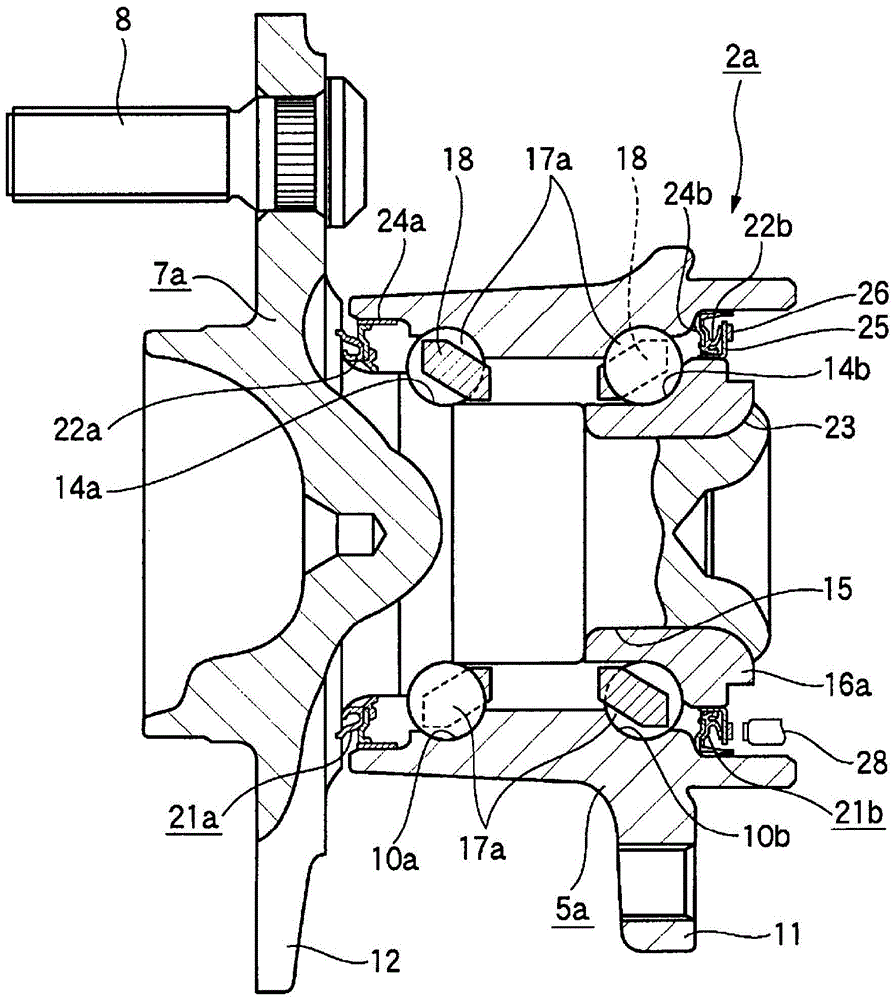

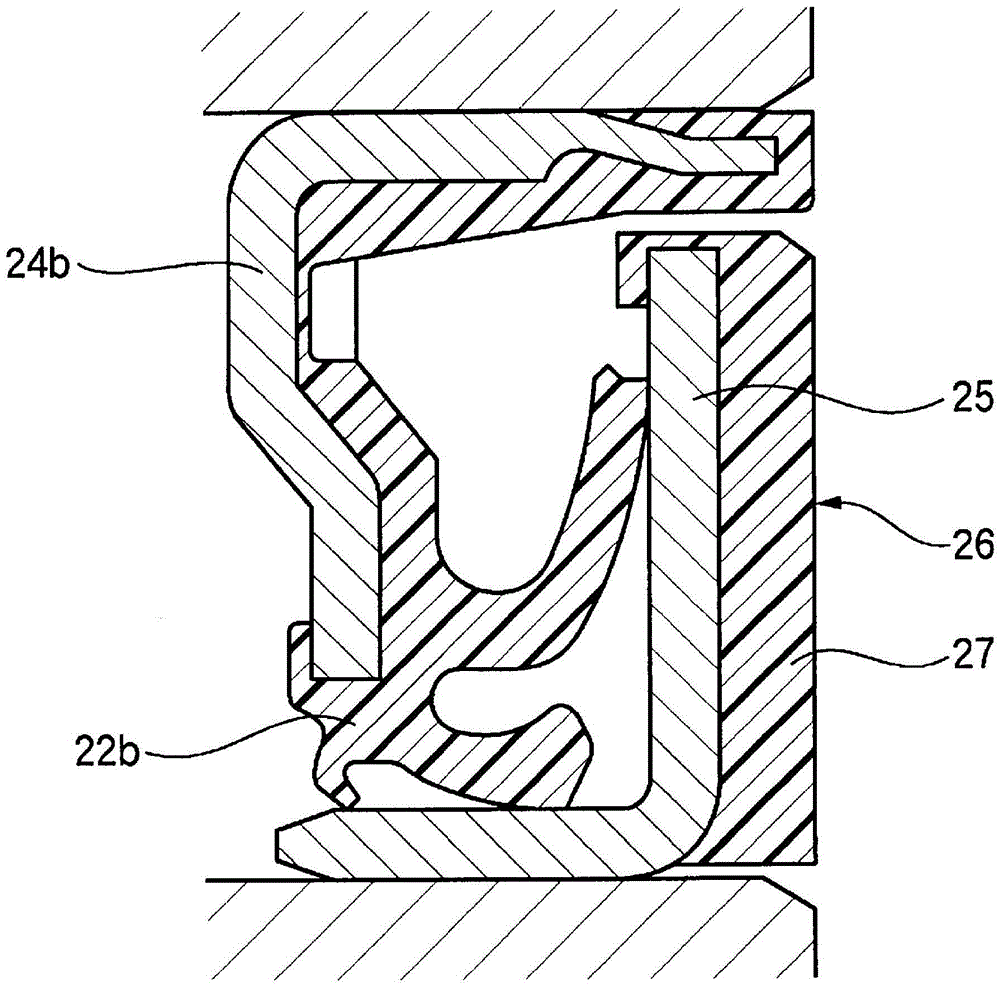

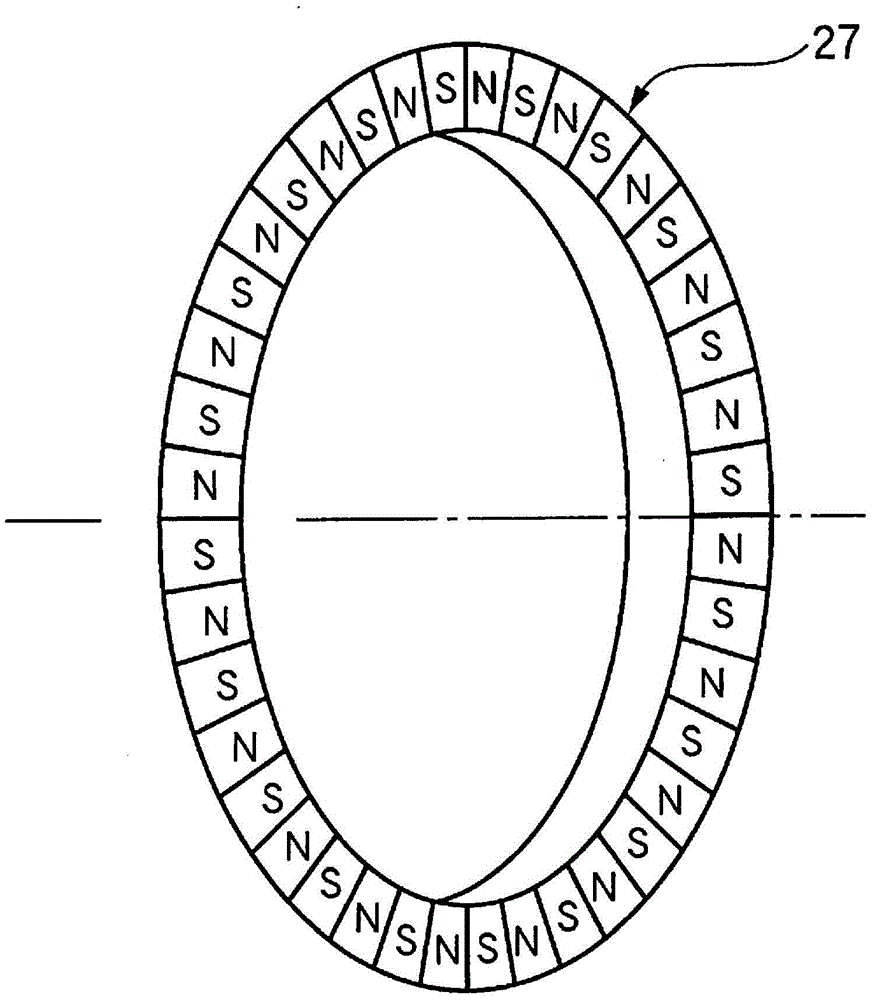

Tone Wheel and Method for Manufacturing The Same

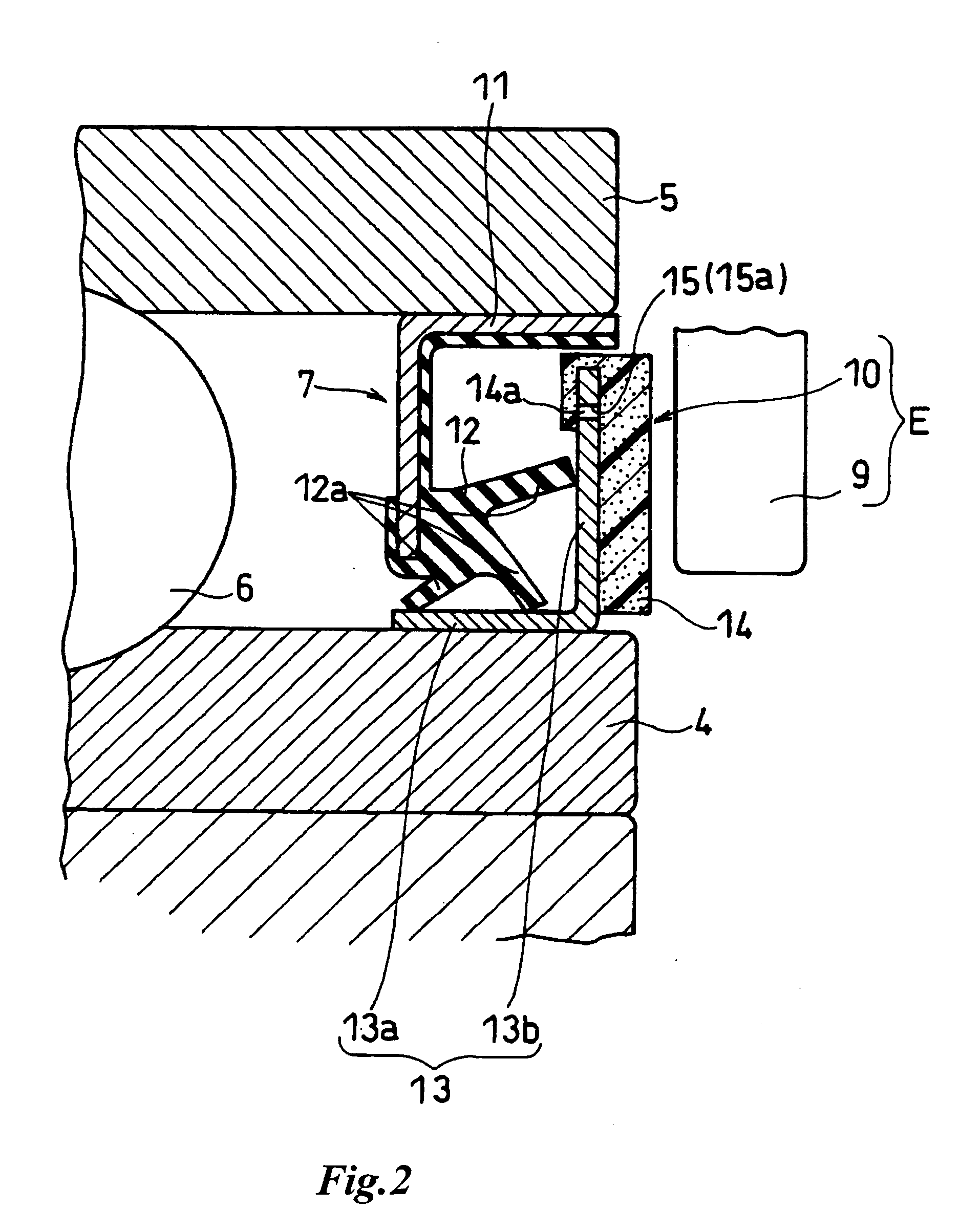

InactiveUS20090219017A1Reliable and reliableAvoid damageElectromagnets without armaturesEngine sealsEngineeringPlastic magnet

A tone wheel constituting a rotation detection magnetic encoder in combination with a magnetic sensor fixed onto a stationary side member, the tone wheel comprising a metal reinforcing ring fitted in a rotary side member and a circular multipolar magnet fixed to the metal reinforcing ring. the circular multipolar magnet is made of a plastic magnet of a circular resin molded product which contains a magnetic powder therein and is magnetized with a number of S and N poles alternatively provided along its circumference. The metal reinforcing ring has a mating portion with which a part of the circular resin molded product mates. The circular resin molded product is a molded product integrally combined with the metal reinforcing ring in which a part of the circular resin molded product mates with the mating portion of the metal reinforcing ring, and is made by charging a melt resin material into a forming die in which the metal reinforcing ring is disposed and hardening the melt resin material. The metal reinforcing ring has at its edge a bent portion which is enwrapped with a part of the circular resin molded product, and the mating portion is provided at the bent portion.

Owner:UCHIYAMA MFG

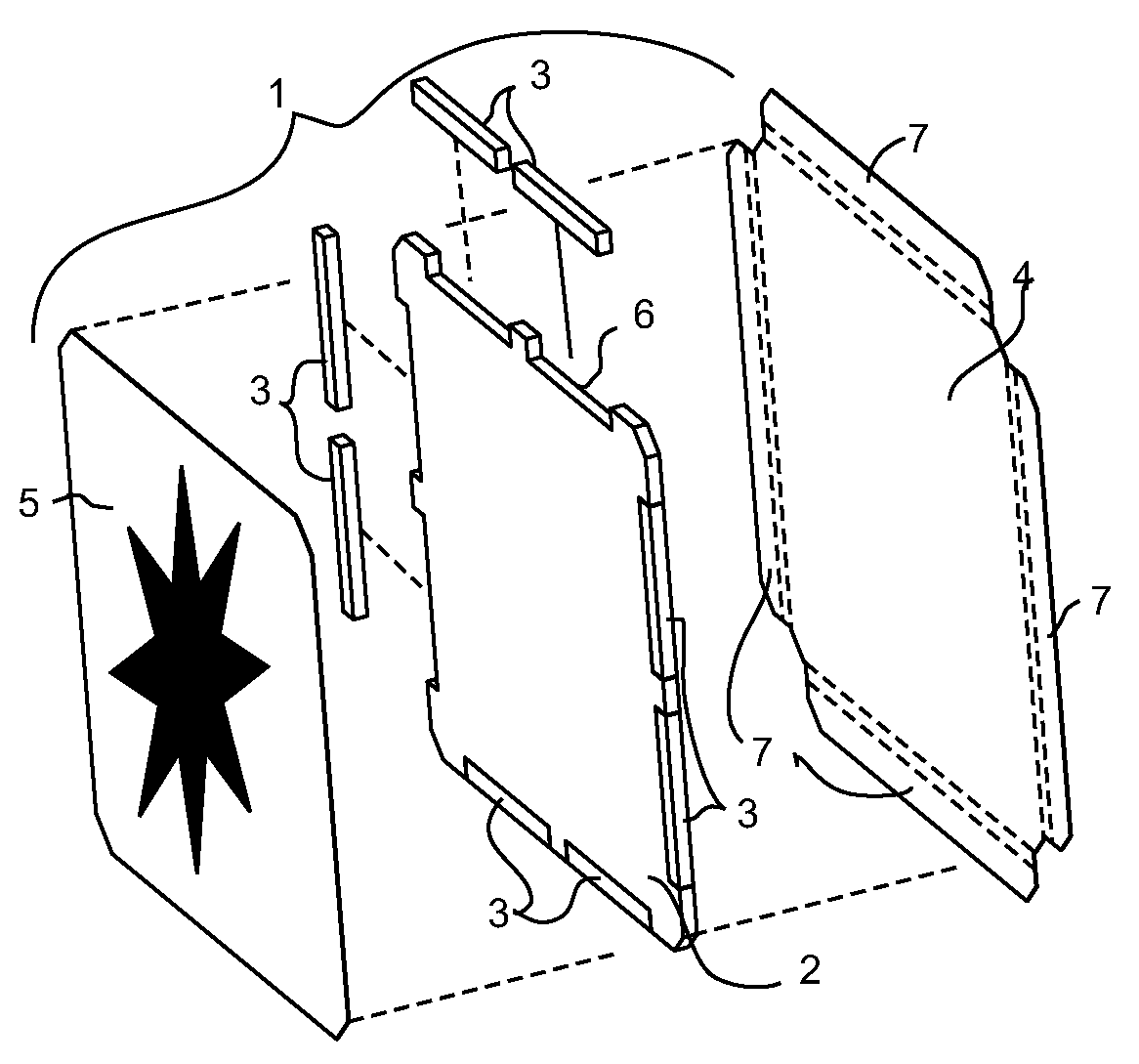

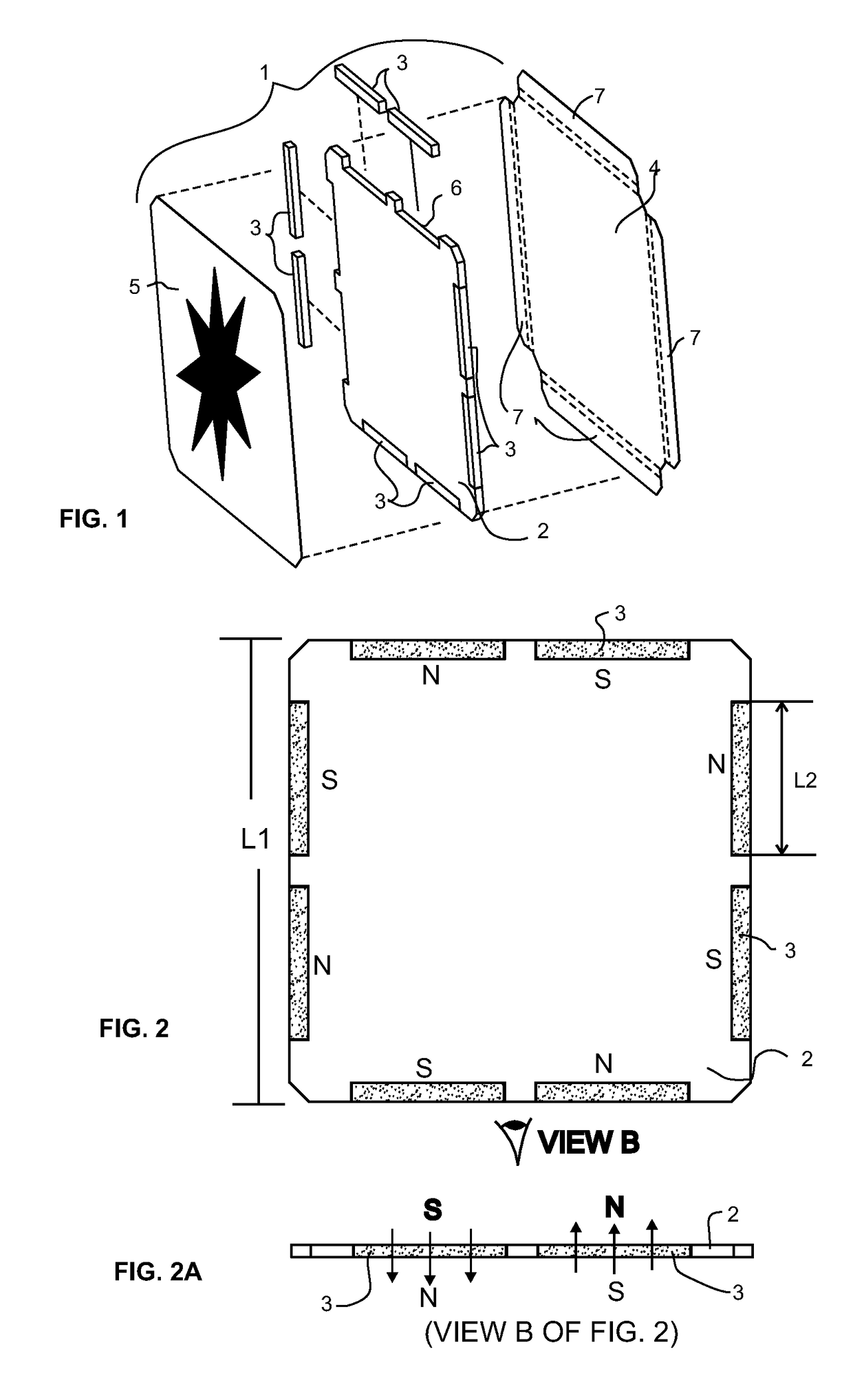

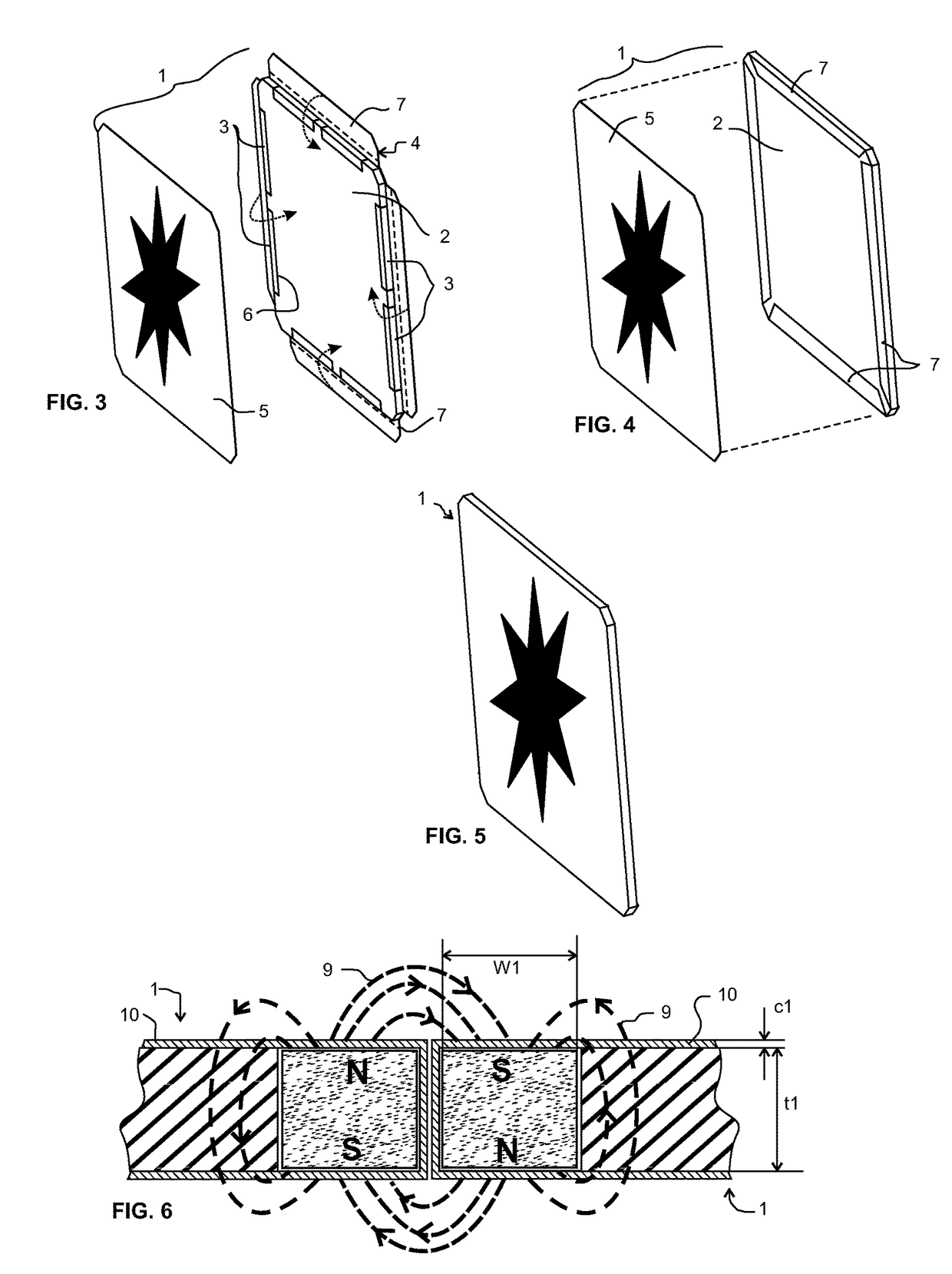

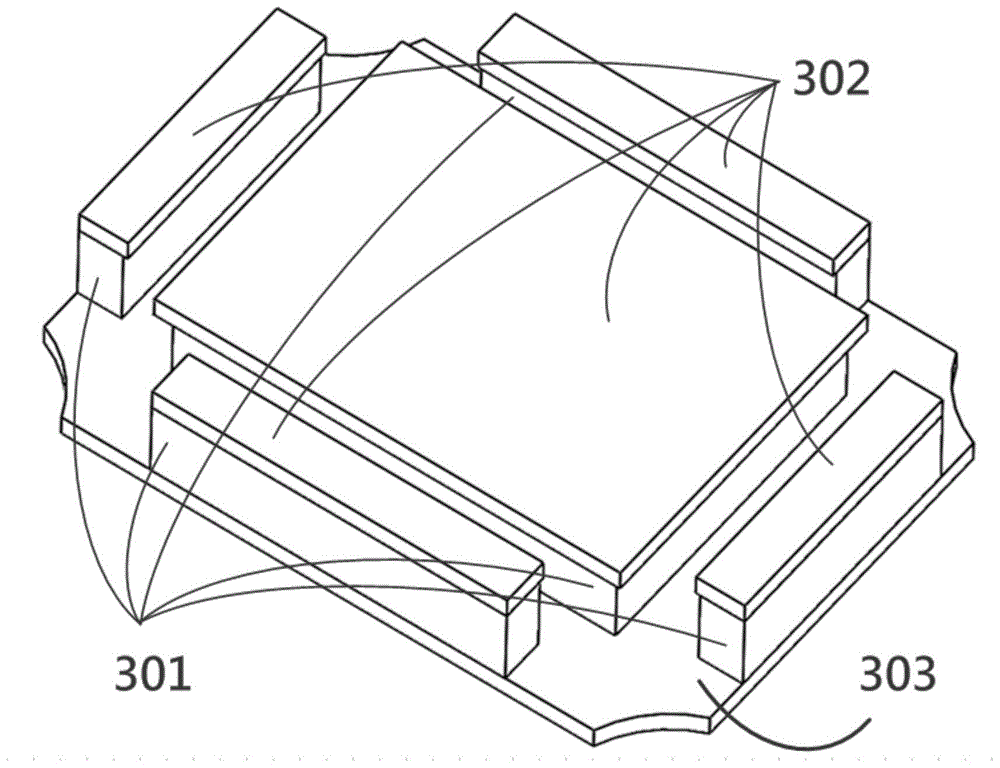

Tile construction set using plastic magnets

Owner:APEX TECH INC

3D printing magnetic field orientation preparing method of plastic magnets

The invention provides a 3D printing magnetic field orientation preparing method of plastic magnets. The method comprises the steps that firstly, a magnetic component, a polymer and other raw materials are prepared; secondly, a computer three-dimensional schematic diagram of the plastic magnets is established, slicing is carried out, and a scanning path is established; thirdly, corresponding printing parameters are set; fourthly, a printing device is started to carry out 3D printing, meanwhile, magnetic particles and the polymer are injected into a printing head, printing is carried out according to the set track and speed after heating and mixing are conducted, in the printing process, a magnetic field is exerted on the work space, the magnetic particles are oriented in the outer magnetic field direction, the magnetic performance is optimized, printing is conducted line by line to form a face, and the three-dimensional plastic magnets are formed through printing conducted layer by layer. The preparing method has the advantages that feeding, melting, mixing, printing and magnetic field orienting are finished at the same time through 3D printing, and the working efficiency is improved; the 3D printing technology is an additive manufacturing method, and compared with a traditional technology, raw materials are saved, and waste is avoided.

Owner:彭晓领

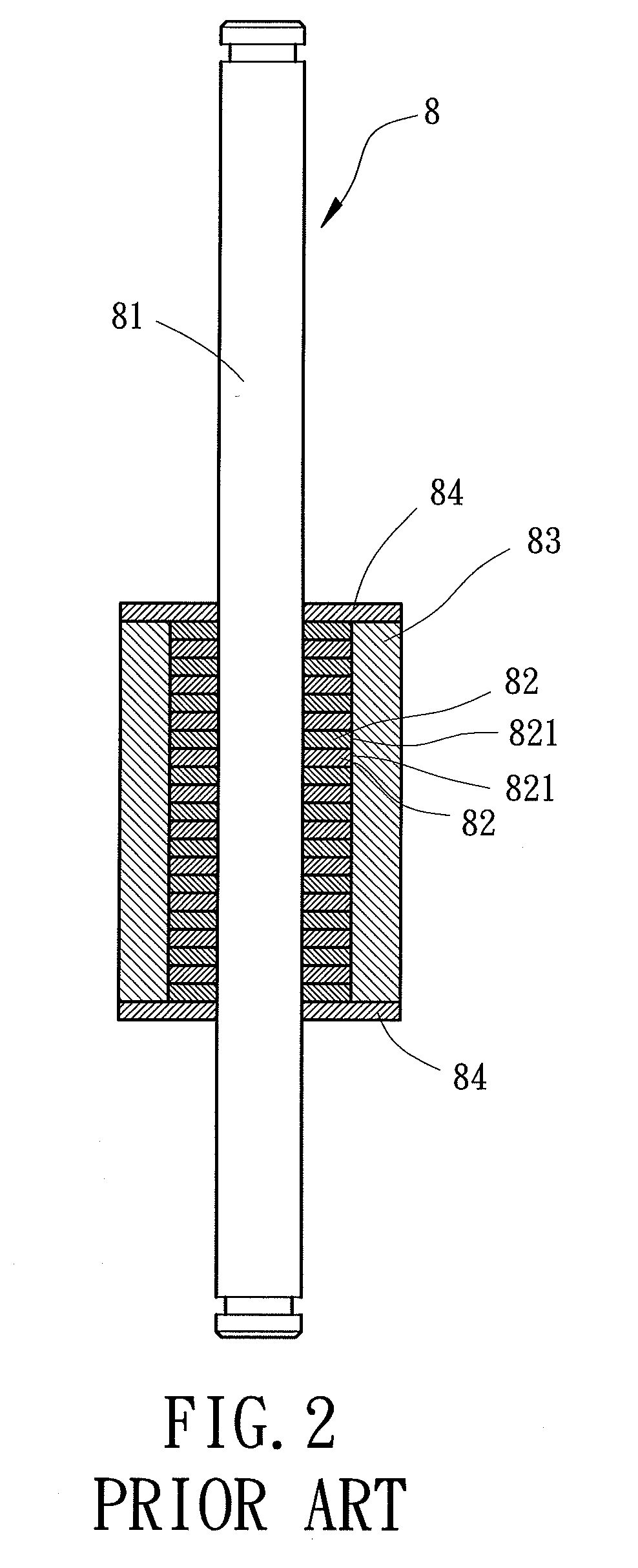

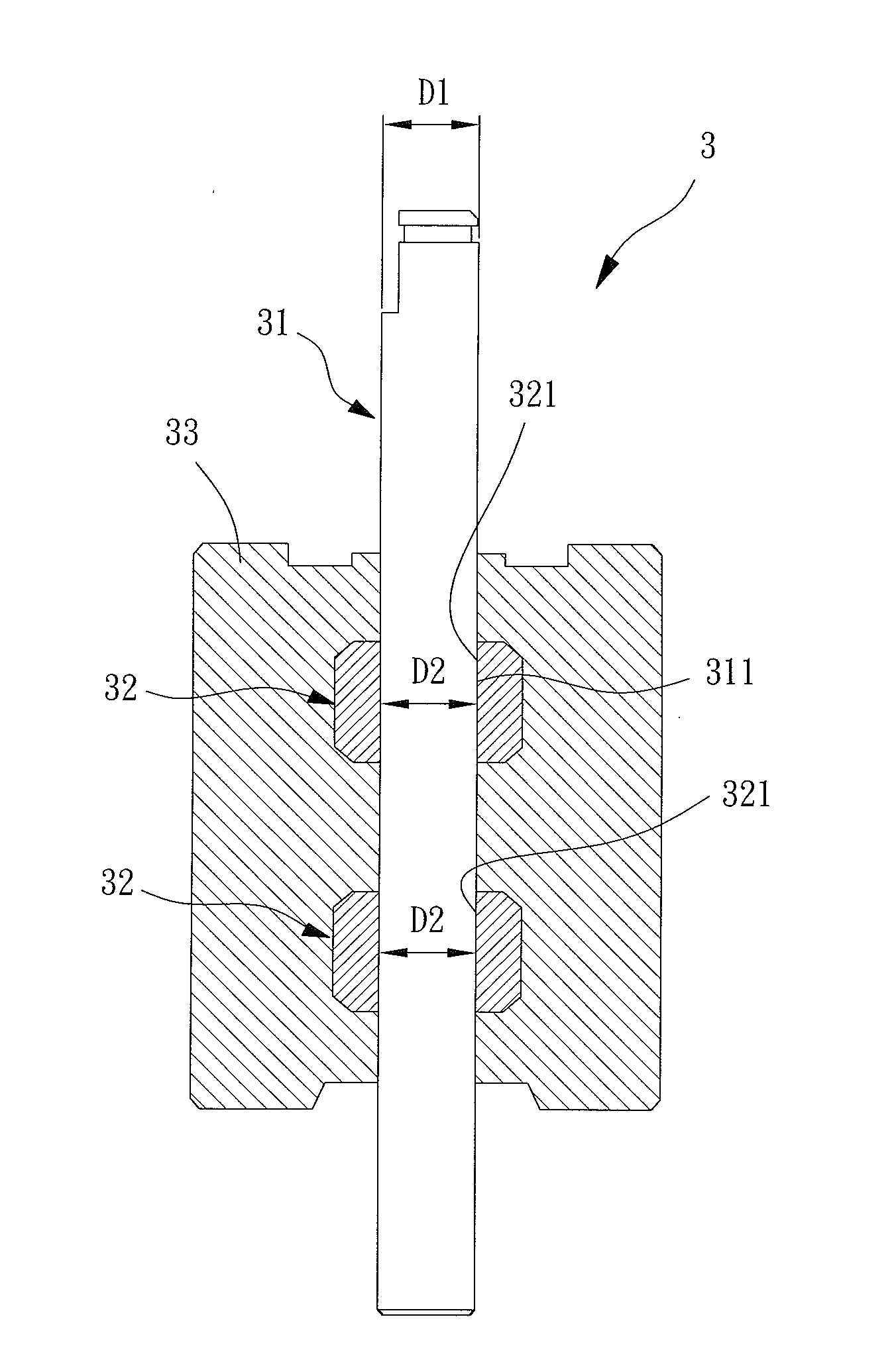

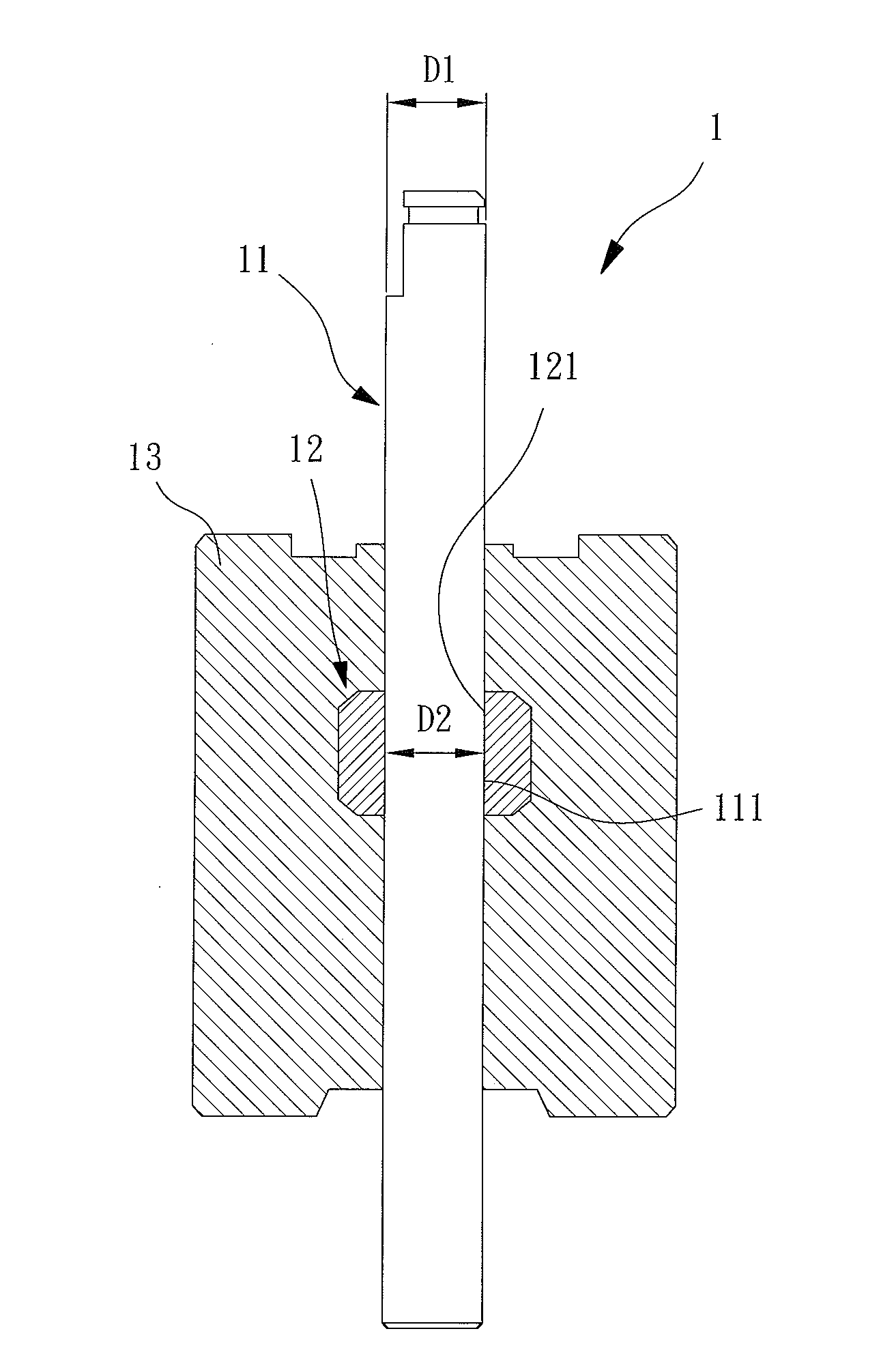

Rotor for motor

InactiveUS8436497B2Improve joint stabilityEasy to assembleMagnetic circuit rotating partsManufacturing stator/rotor bodiesCouplingEngineering

A rotor for a motor includes a shaft having an outer periphery with an engaging portion. At least one coupling member includes an engaging hole. The shaft extends through the engaging hole of the at least one coupling member. The at least one coupling member is engaged with the engaging portion of the shaft by tight coupling. A plastic magnet envelops the shaft and the at least one coupling member by injection molding. The at least one coupling member prevents the plastic magnet from disengaging from the shaft, providing enhanced engaging effect while reducing structural complexity and enhancing assembling convenience.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Rotor for Motor

InactiveUS20120062050A1Improve joint stabilityEasy to assembleMagnetic circuit rotating partsManufacturing dynamo-electric machinesCouplingEngineering

A rotor for a motor includes a shaft having an outer periphery with an engaging portion. At least one coupling member includes an engaging hole. The shaft extends through the engaging hole of the at least one coupling member. The at least one coupling member is engaged with the engaging portion of the shaft by tight coupling. A plastic magnet envelops the shaft and the at least one coupling member by injection molding. The at least one coupling member prevents the plastic magnet from disengaging from the shaft, providing enhanced engaging effect while reducing structural complexity and enhancing assembling convenience.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

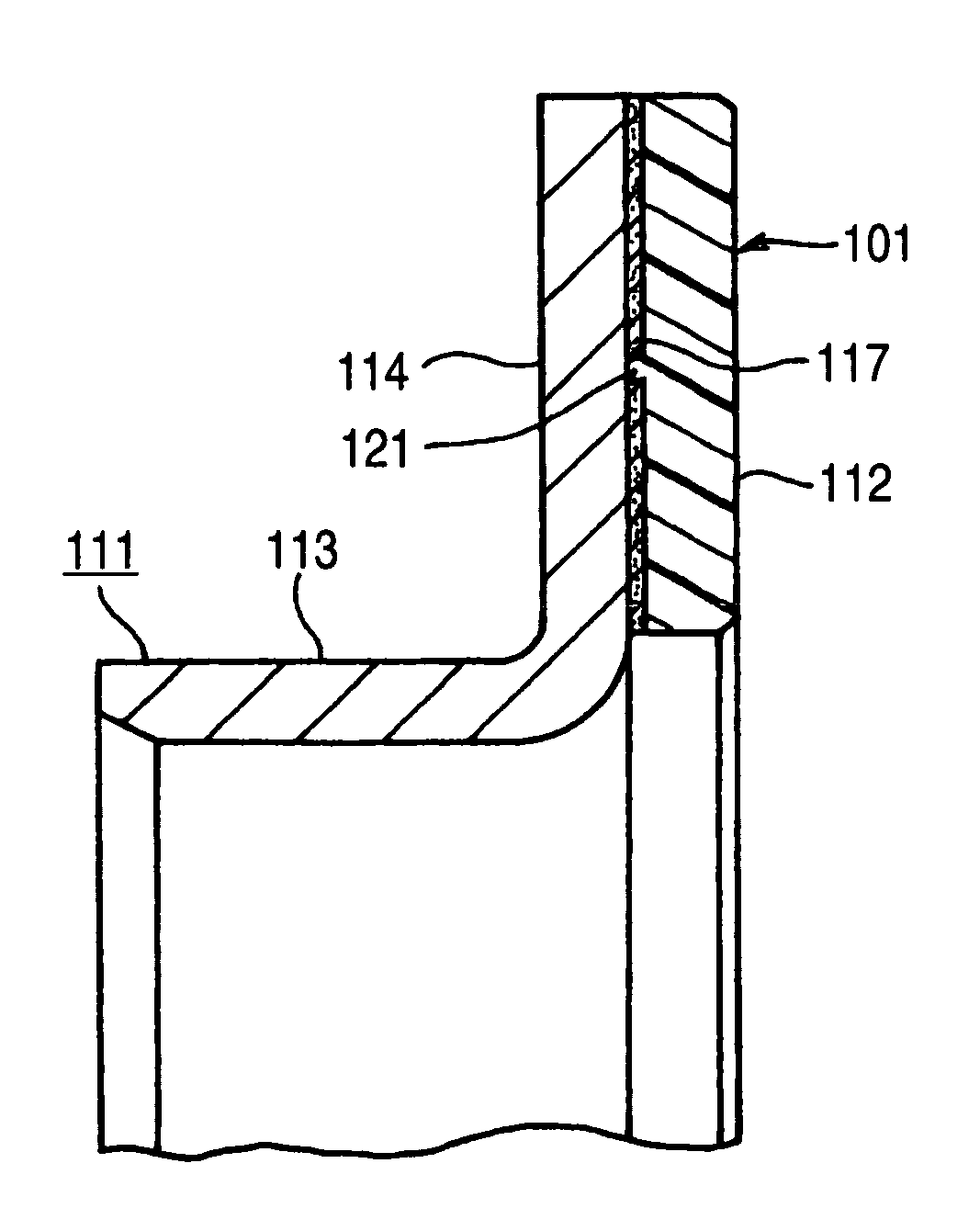

Tone Wheel

InactiveUS20100007450A1Maintain measurement accuracyReliable detectionRolling contact bearingsBearing assemblyAdhesiveEngineering

A tone wheel constituting a rotation detection magnetic encoder in combination with a magnetic sensor fixed onto a stationary side member, the tone wheel comprising a metal reinforcing ring fitted in a rotary side member and a circular multipolar magnet fixed to the metal reinforcing ring. the circular multipolar magnet is made of a plastic magnet of a circular resin molded product which contains a magnetic powder therein and is magnetized with a number of S and N poles alternatively along its circumference; the circular multipolar magnet is fixed to a surface of the metal reinforcing ring opposed to the magnetic sensor with an adhesive; and a restraint portion is provided at a part of the portion wherein the circular multipolar magnet is fixed to the metal reinforcing ring, thereby fixation of the circular multipolar magnet to the metal reinforcing ring is reinforced and depart of the circular multipolar magnet from the metal reinforcing ring is prevented.

Owner:UCHIYAMA MFG

Magnetically actuated endoscope coupler

An endoscopic coupler by which the rotary and / or linear motion of an external ring is transferred via magnetic interaction of specially configured continuous plastic magnets to a lens resident in a hermetically sealed housing to effect focusing and / or zooming action of the lens without mechanically breaching the integrity of the hermetic seal thereby making the coupler particularly suitable for withstanding the rigors of autoclaving.

Owner:LIGHTHOUSE IMAGING

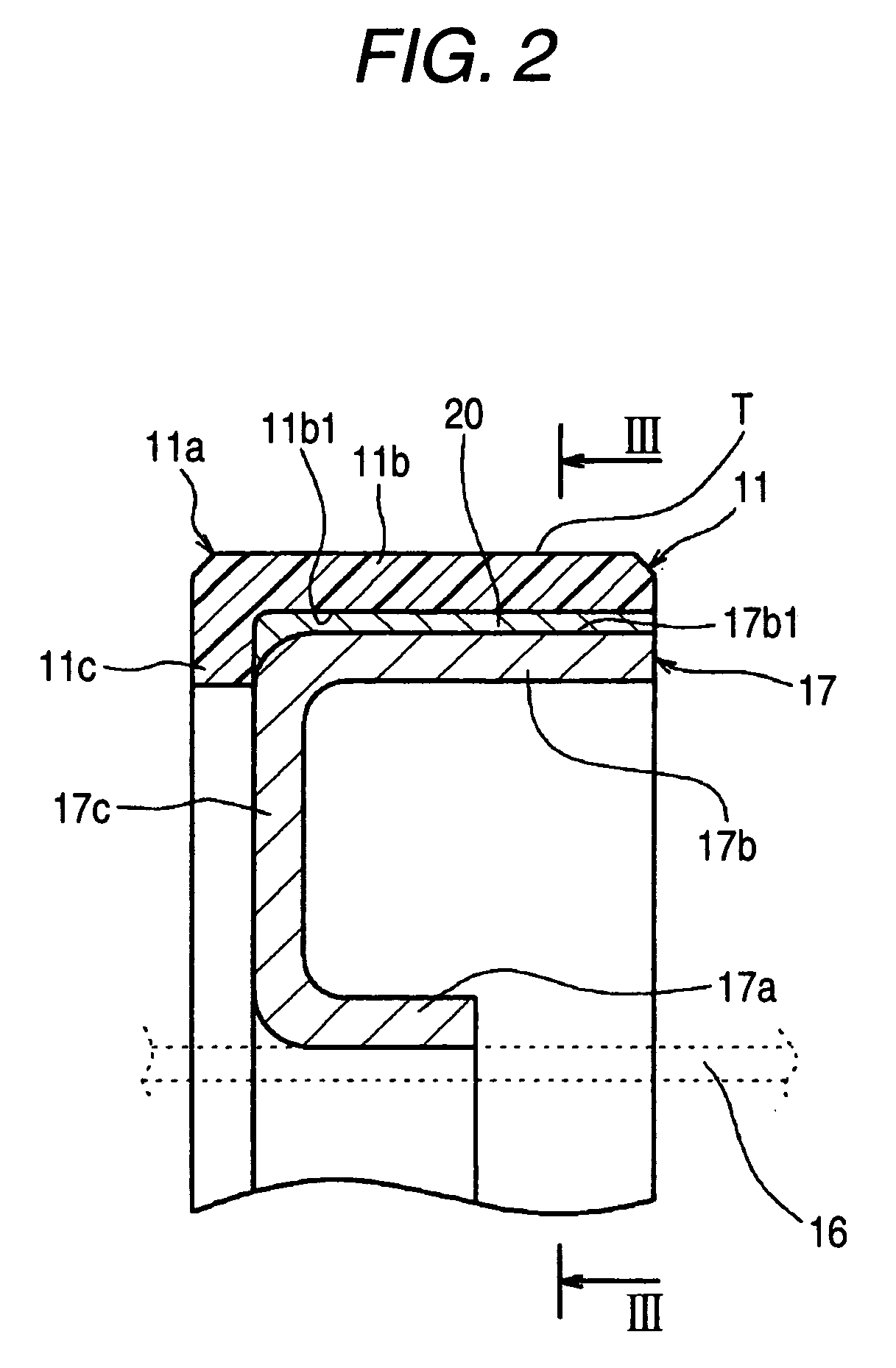

Magnetized pulsar ring, and rolling bearing device with sensor using the same

InactiveUS20080218161A1Reduce the differenceRelieve stressEngine sealsRolling contact bearingsPulsarElastomer

A magnetized pulsar ring of the invention is a pulsar ring fixed to an outer peripheral surface of a supporting member and including a ring body in which a number of magnetic poles are at predetermined intervals in a peripheral direction. The ring body 11a is formed of a plastic magnet, and has a cushion member made of an elastic body that is interposed between the ring body and the outer peripheral surface.

Owner:JTEKT CORP

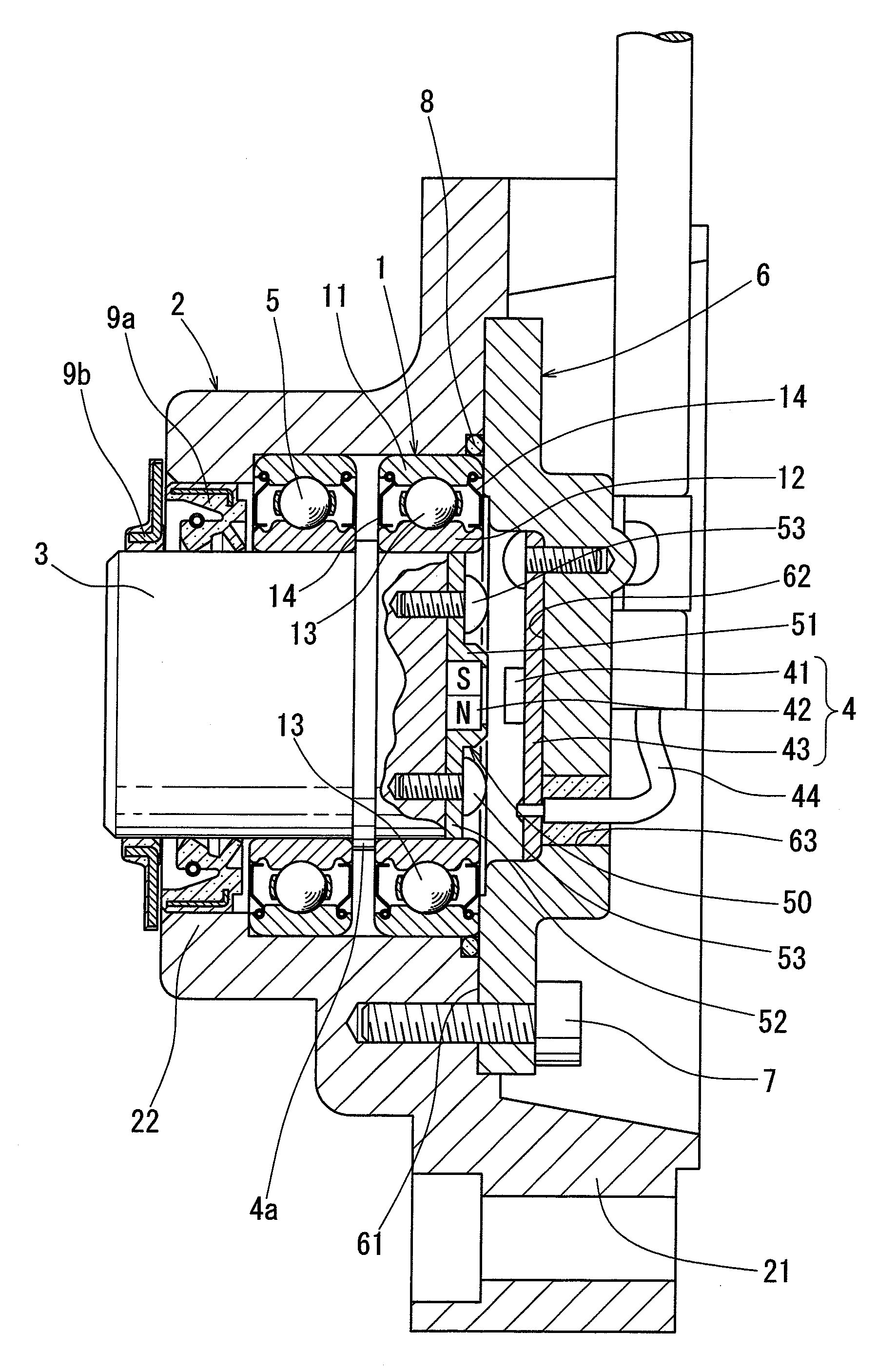

Rotation sensor unit

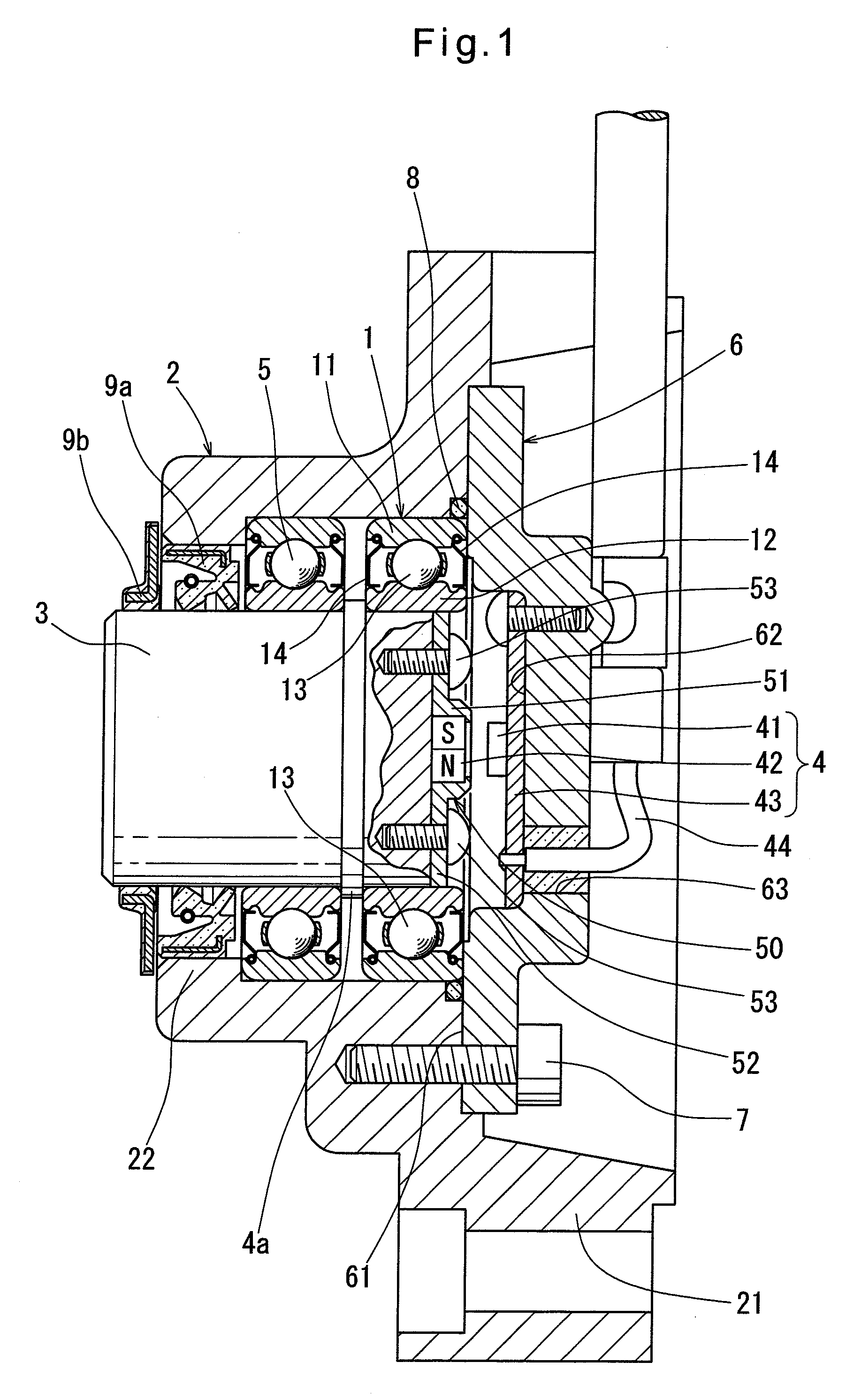

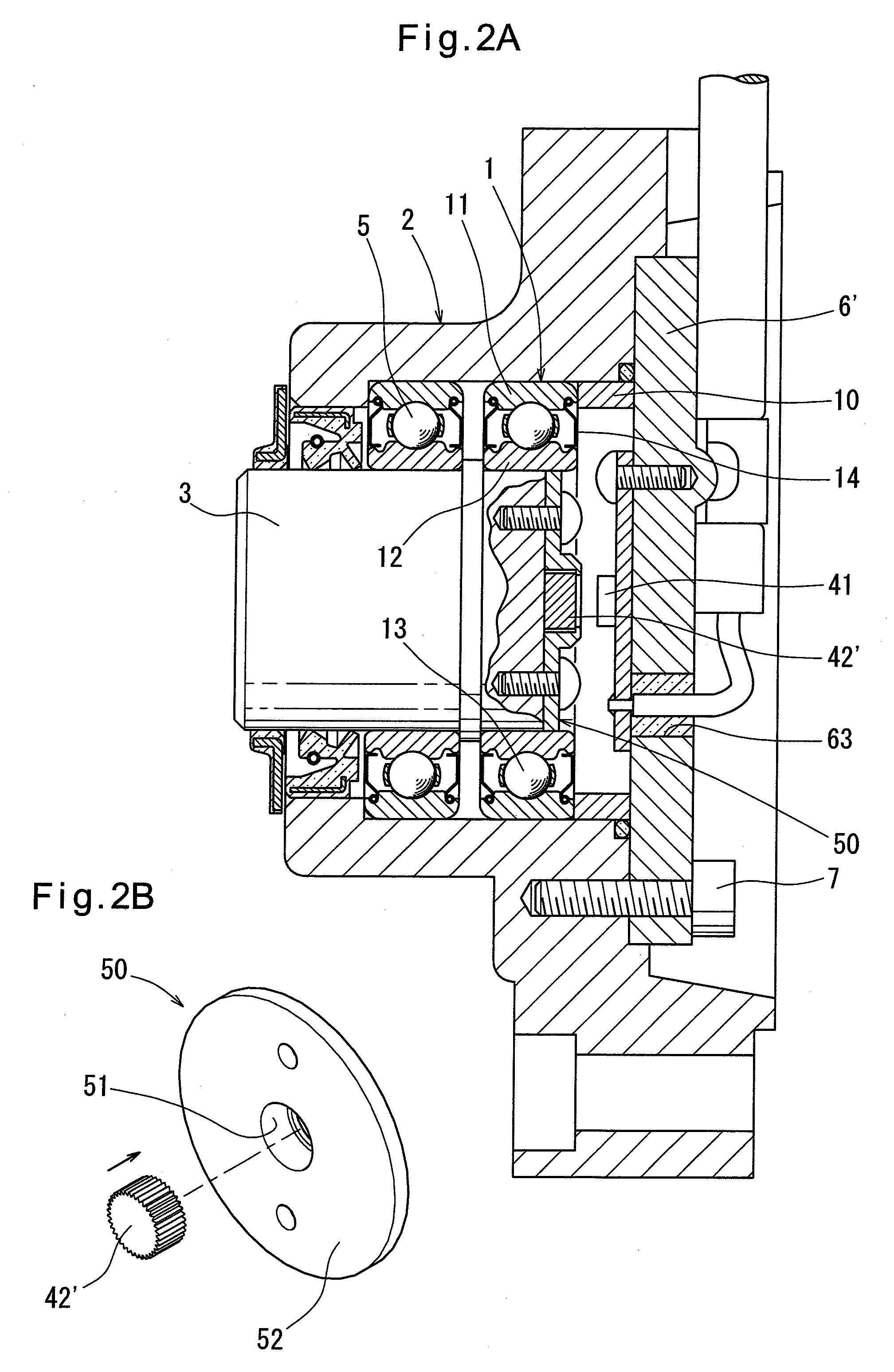

ActiveUS20090243600A1Avoid negative effectsImprove rigidityBearing assemblyUsing electrical meansRolling-element bearingEngineering

A rotation sensor unit includes an encoder, a holder radially positioning the encoder, and a rolling bearing having an inner race. The rolling bearing is fitted around the shaft so that one end of the inner diameter surface of the inner race protrudes from the end of the outer diameter surface of the shaft. The holder has a screwed portion fitted in the inner race, positioning the encoder coaxially with the shaft. The holder is non-magnetic, having a retaining portion in which the encoder is axially pressed. The encoder is a plastic magnet, with protrusions and recesses formed integrally on its outer diameter surface and biting the inner diameter surface of the retaining portion to prevent the encoder from rotating. With the holder screwed to the shaft, the encoder is disposed between the magnetism detection element and the one end of the shaft.

Owner:NTN CORP

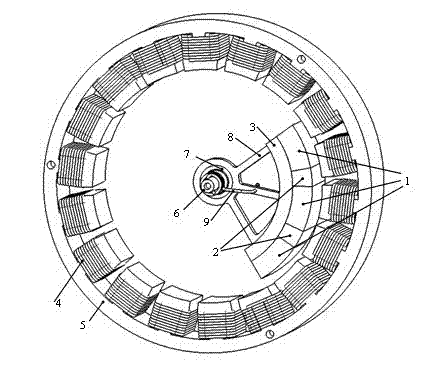

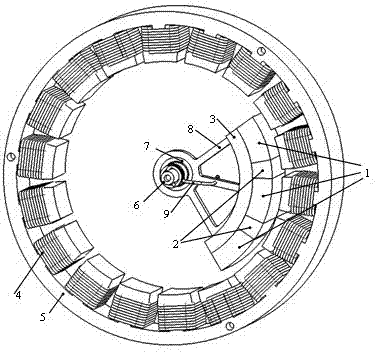

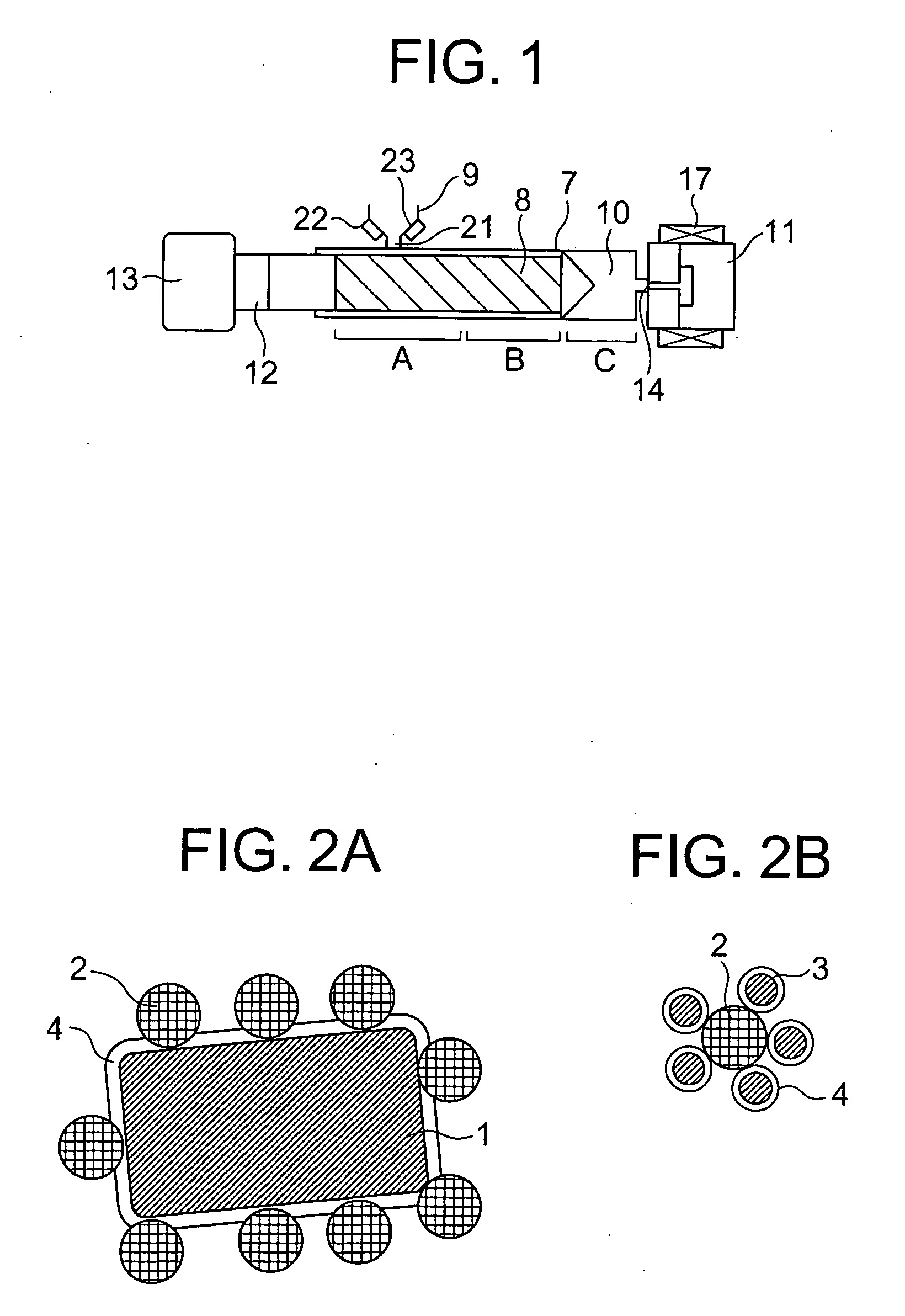

Device and method for collecting human kinetic energy and converting human kinetic energy into electric energy

ActiveCN102237770AExpand sourceImprove utilizationFrom muscle energyMachines/enginesBall bearingElectrical battery

The invention discloses a device and a method for collecting human kinetic energy and converting the human kinetic energy into electric energy. The device comprises permanent magnets, plastic magnet separation blocks, an armature, a ball bearing, a bracket, a torsion spring, an electrical steel core and coils wound on the internal teeth of the electrical steel core, wherein the permanent magnets and the plastic magnet separation blocks are distributed at intervals, absorbed onto the armature and fixed on the bracket; the ball bearing is embedded into one end of the bracket to form a rotor system; one end of the torsion spring is fixed on a shaft, and the other end of the torsion spring is fixed on the bracket to form a bi-oscillation system with the rotor system; the coils, the permanent magnets and the armature form a magnetic field loop; and the bi-oscillation system converts the external human kinetic energy into the rotation of the rotor system, and the current of unstable voltageis generated by the coils in a varying magnetic field, and the current, and then is regulated into the current of stable voltage. The device provided by the invention is simple and easy to manufacture, and can automatically recycle the human kinetic energy so as to expands available energy sources, improve the utility of portable electronic equipment and reduce the environmental pollutions of used batteries and the like.

Owner:SOUTH CHINA UNIV OF TECH

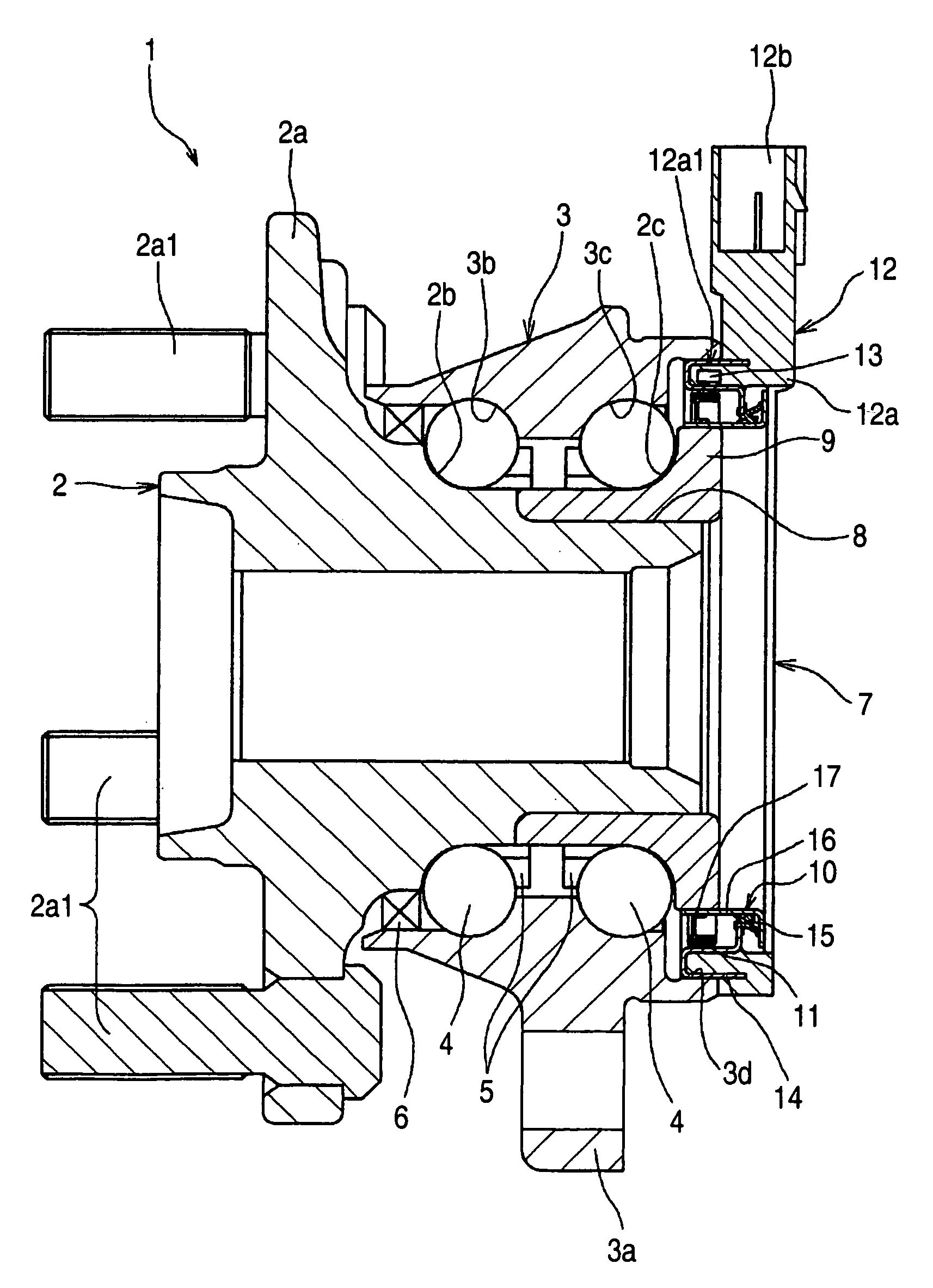

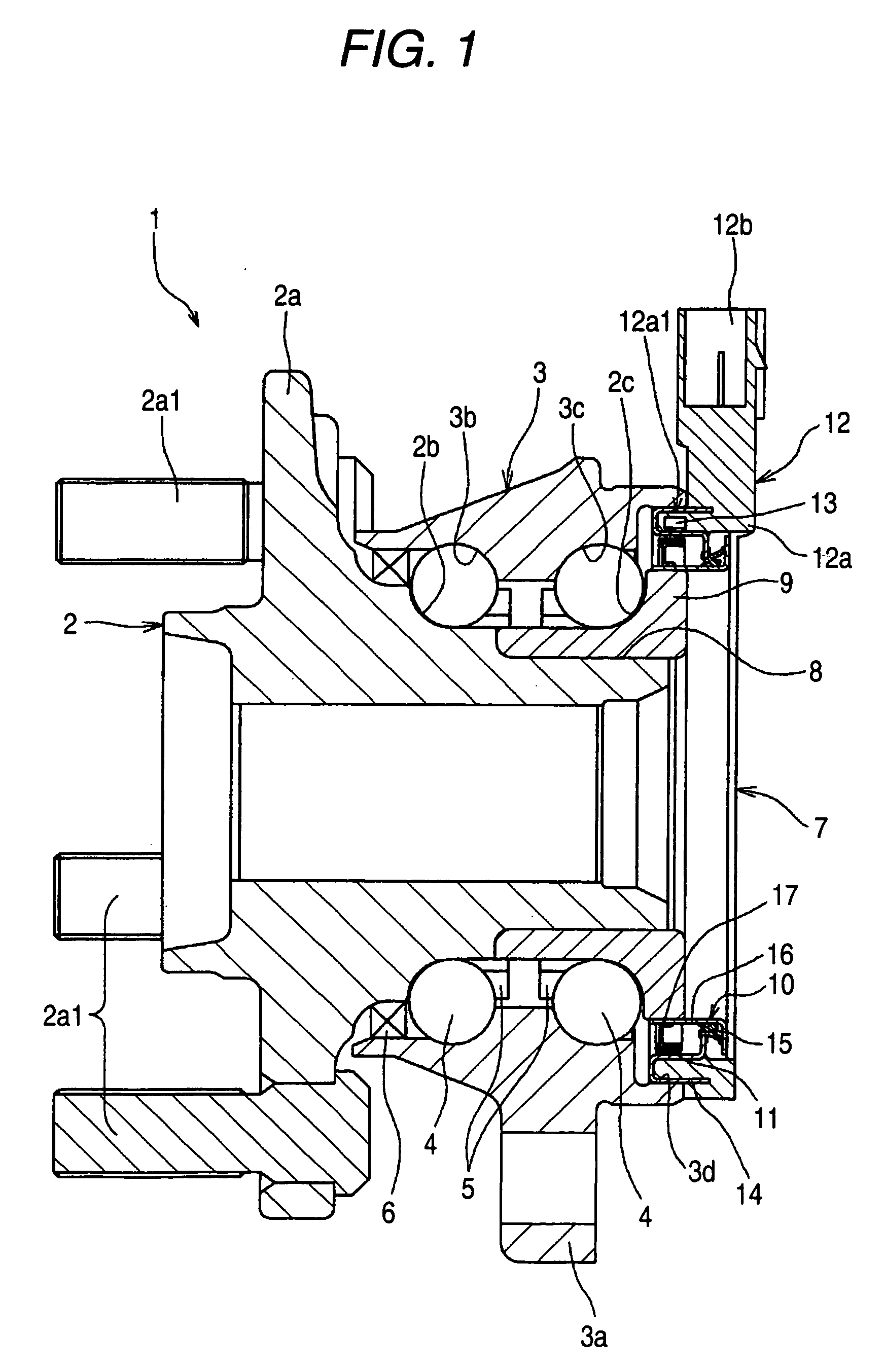

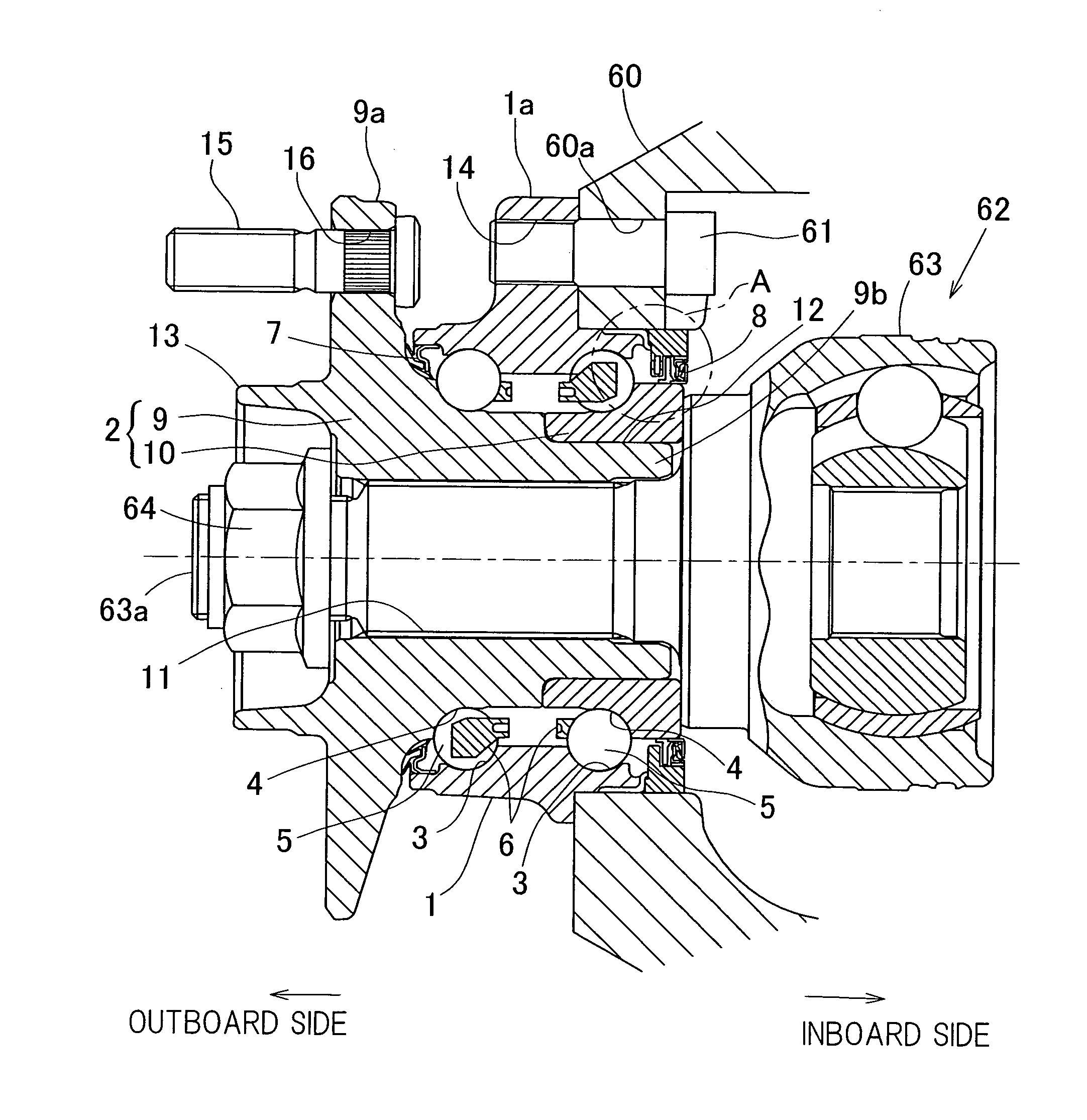

Wheel bearing device with rotation detector

InactiveUS20100301847A1Accurate detectionImprove AssemblabilityRolling contact bearingsBearing assemblyPlastic magnetSensor holder

A wheel support bearing assembly for supporting a wheel, which assembly includes an outer member having rolling surfaces and serving as a stationary member; an inner member having rolling surfaces; a plurality of rows of rolling elements interposed between the respective rolling surfaces; a magnetic encoder fitted to the outer peripheral surface of the inner member at a location adjacent one end thereof; an annular sensor holder made of resin and fitted to the outer member through a core metal, the annular sensor holder having a built-in magnetic sensor with an axial gap intervening between it and the magnetic encoder; and a sealing unit arranged on an outer side axially outwardly of the encoder and the sensor for sealing a space between the sensor holder and the inner member. The magnetic encoder includes a plastic magnetic encoder having a plastic magnet defining a to-be-detected portion.

Owner:NTN CORP

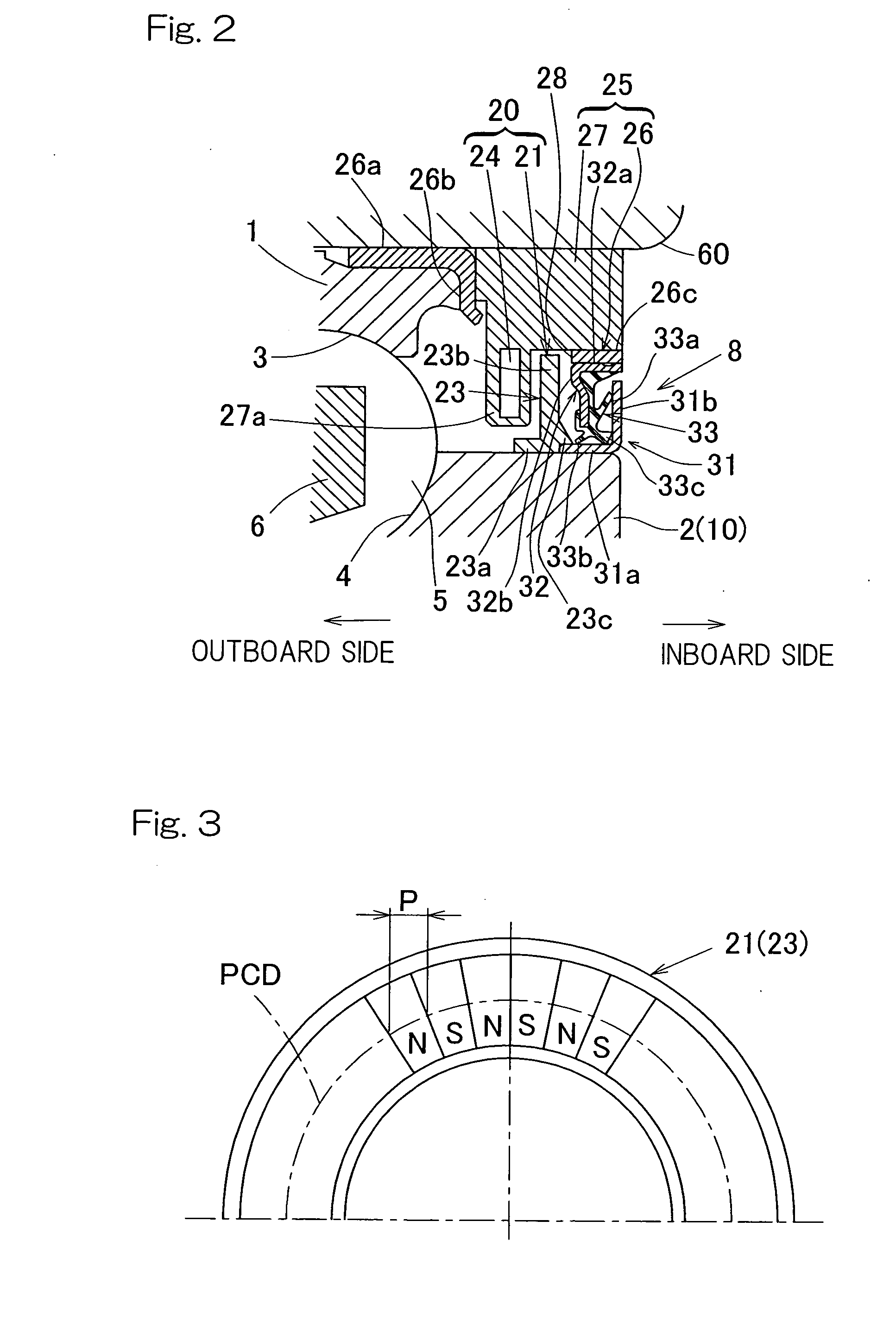

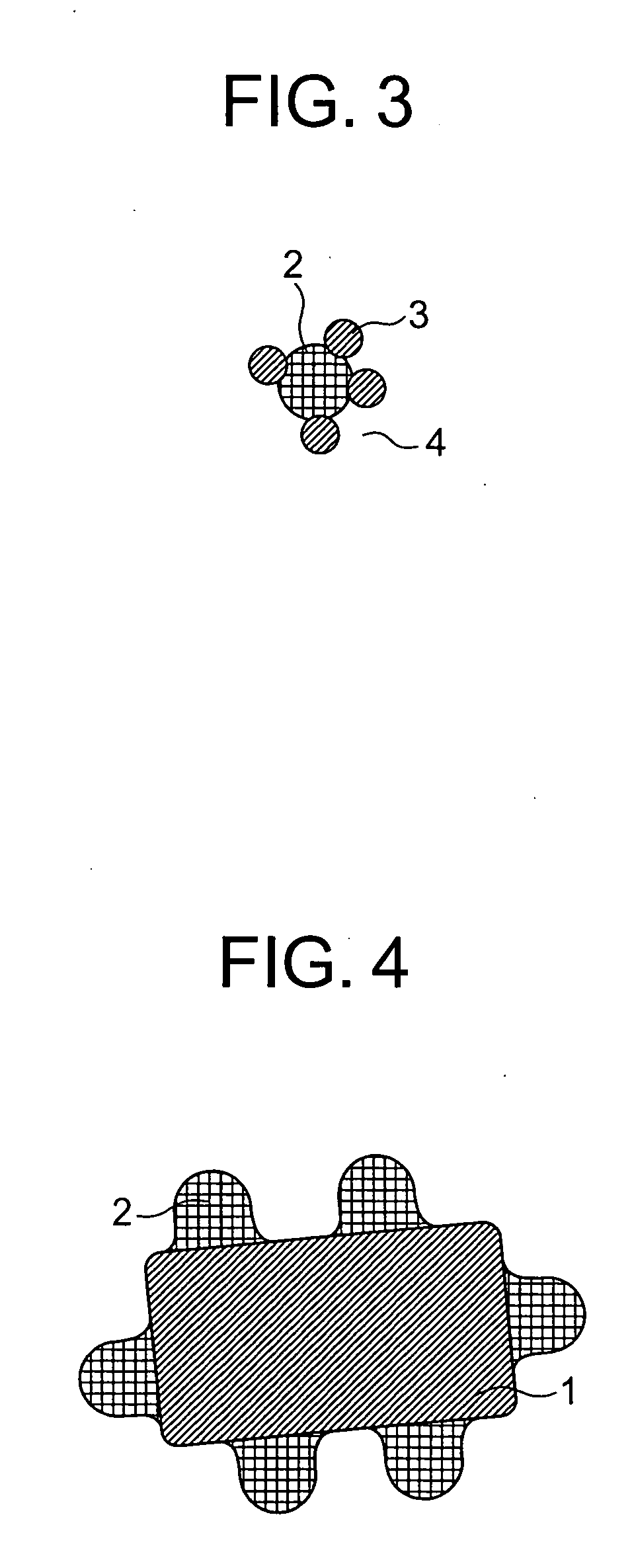

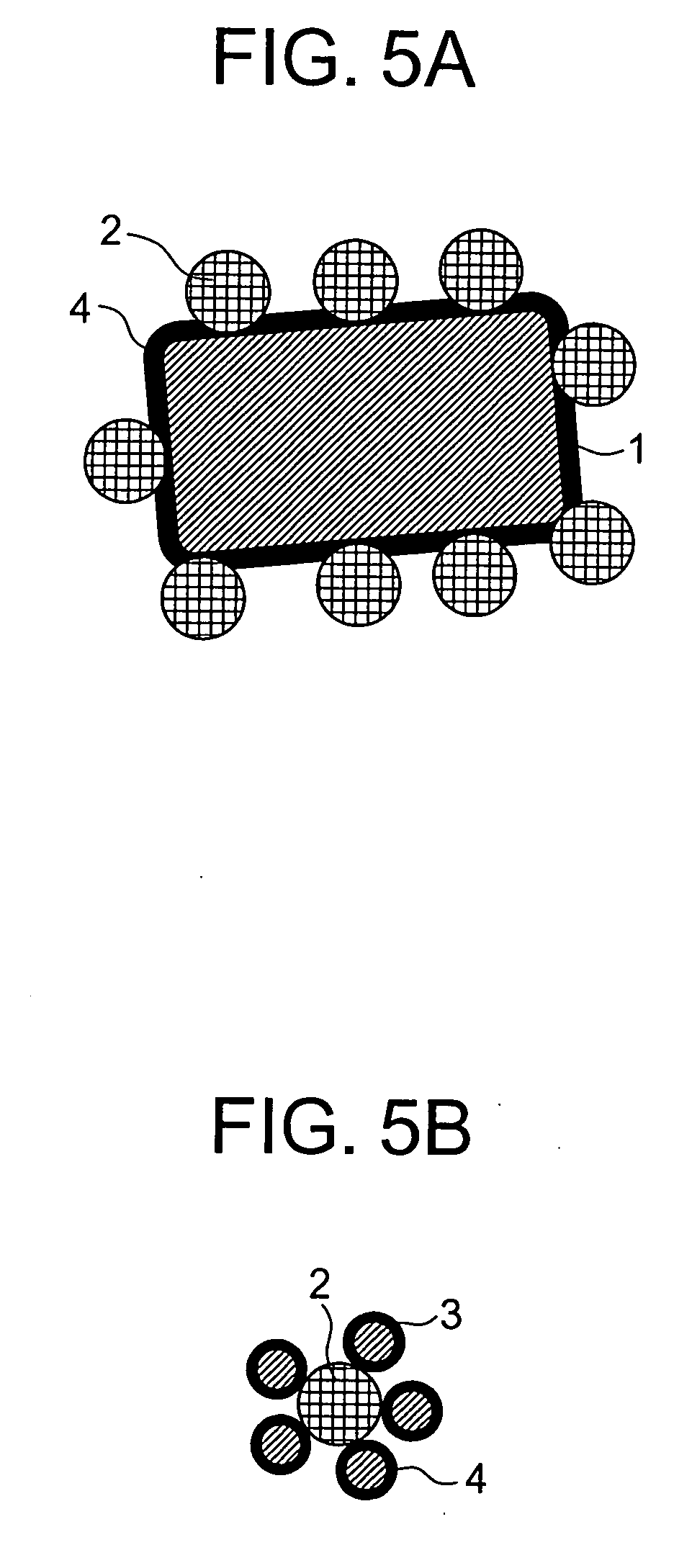

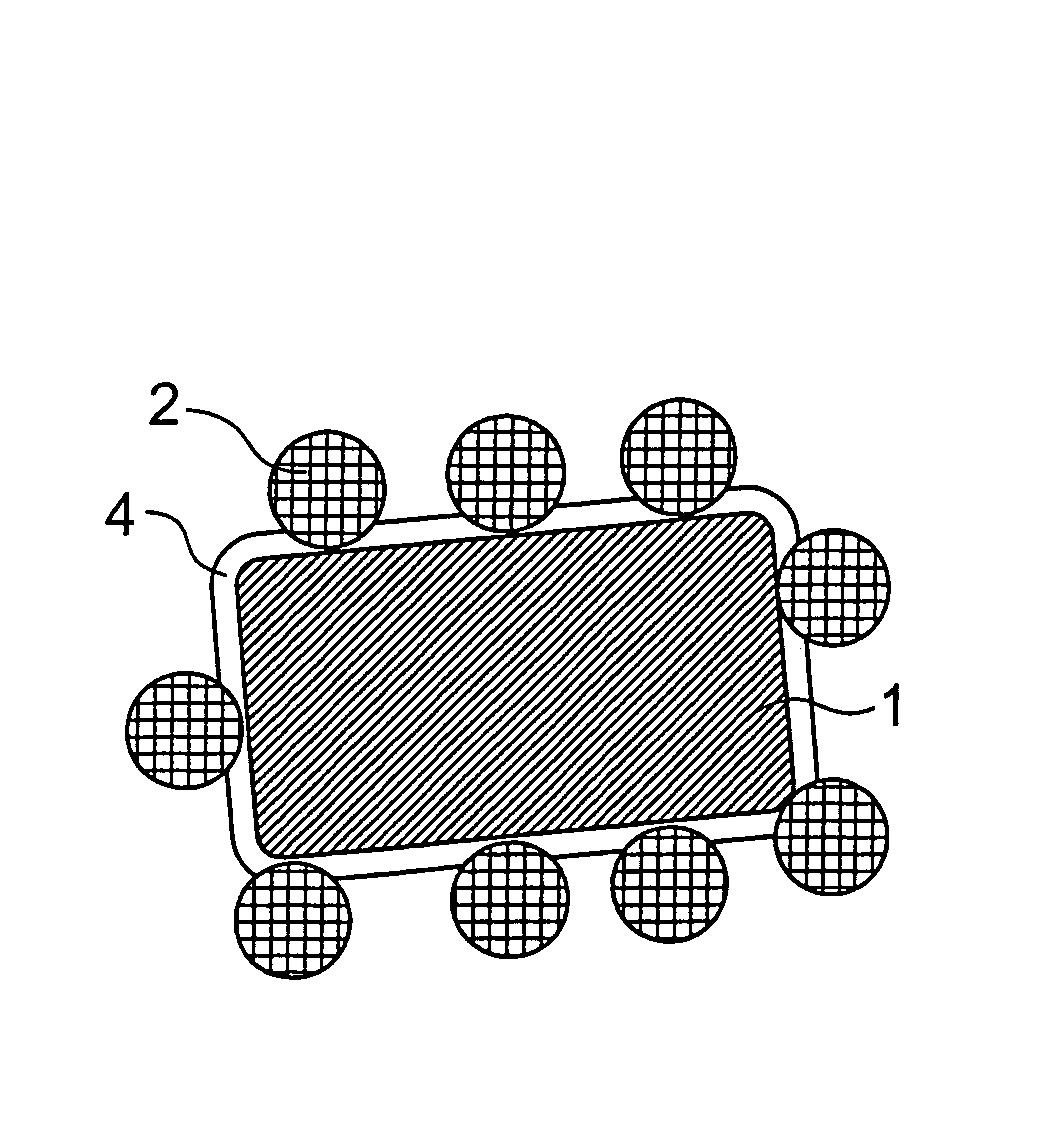

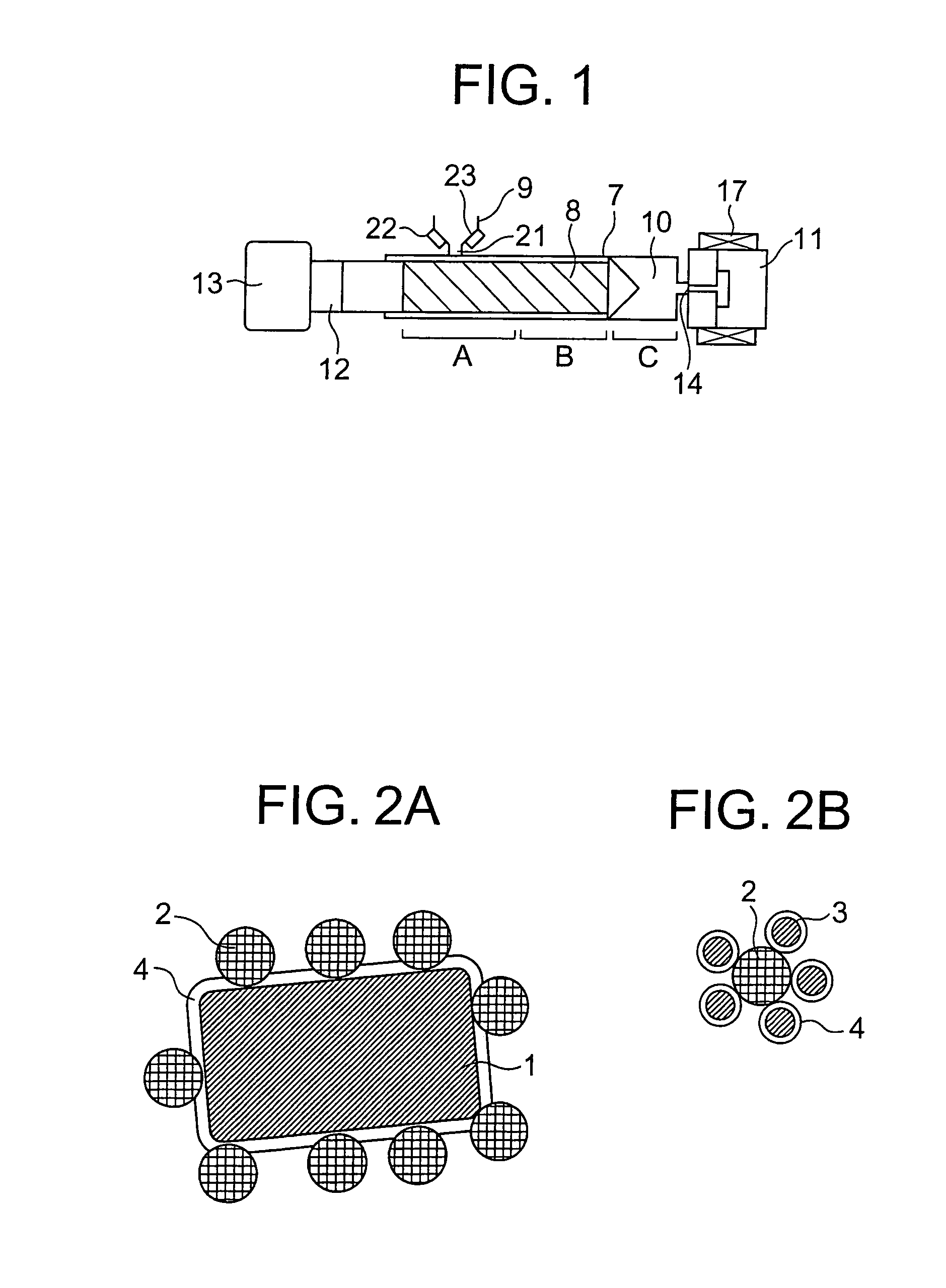

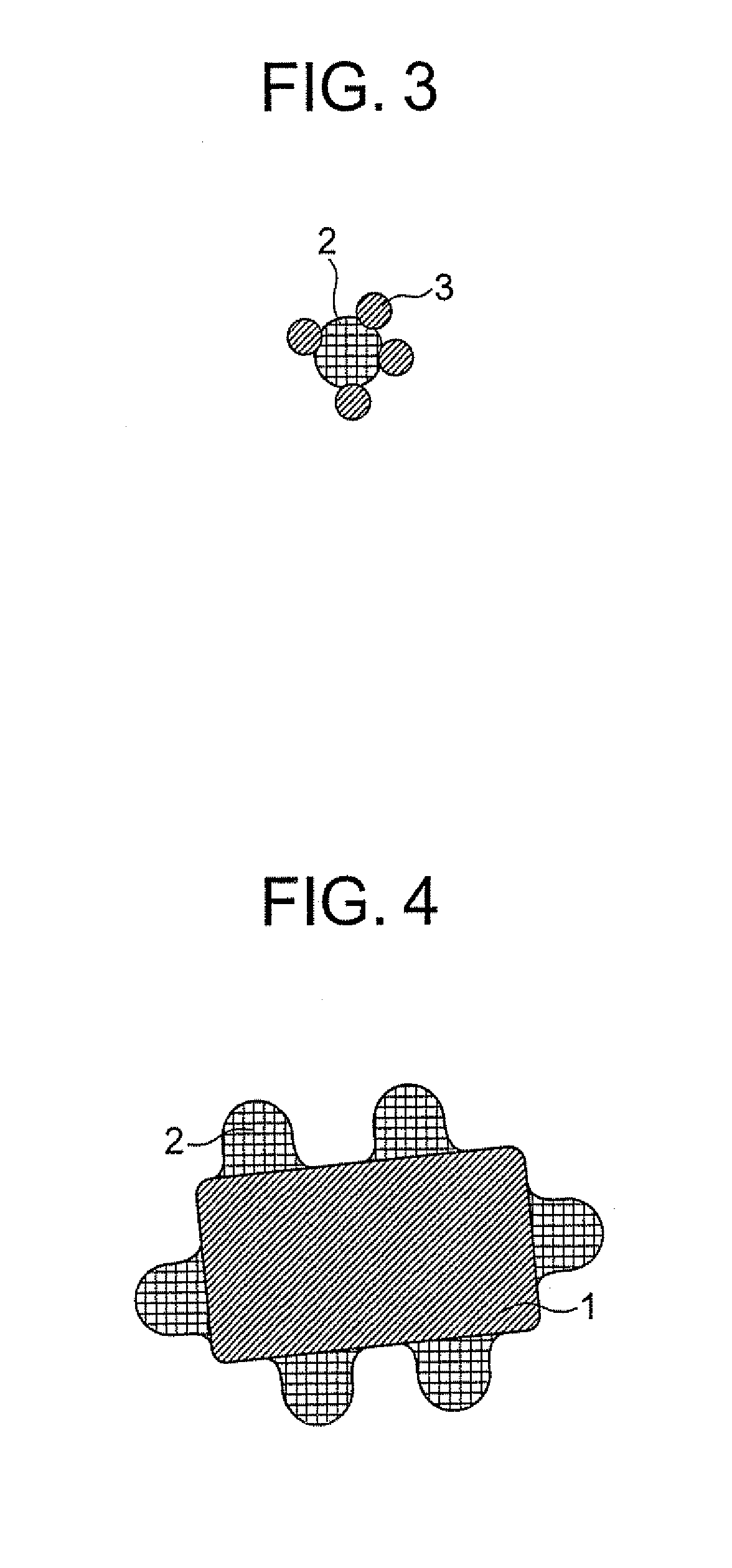

Plastic magnet precursor, production method for the same, and plastic magnet

InactiveUS20060226393A1Improve suppression propertiesQuality improvementInorganic material magnetismInductances/transformers/magnets manufactureConstant compositionShell molding

The present invention provides a plastic magnet precursor which can be supplied to a step of molding a plastic magnet at a constant composition without requiring a kneading step in which a resin is melted and sheared. Through injection molding using the precursor, a plastic magnet having little deterioration of magnetic properties and a small variation in quality is obtained. The plastic magnet precursor according to the present invention includes an Nd—Fe—B isotropic magnet powder (1) and a ferrite anisotropic magnet powder subjected to a coating treatment with a titanate coupling agent (4), and a thermoplastic resin powder (2) is adhered around the magnet powder (1) to form a powder shape.

Owner:MITSUBISHI ELECTRIC CORP

Magnetized pulsar ring, and rolling bearing device with sensor using the same

InactiveUS7812599B2Change damageSuppresses deterioration of magnetic propertiesEngine sealsRolling contact bearingsPulsarElastomer

A magnetized pulsar ring of the invention is a pulsar ring fixed to an outer peripheral surface of a supporting member and including a ring body in which a number of magnetic poles are at predetermined intervals in a peripheral direction. The ring body 11a is formed of a plastic magnet, and has a cushion member made of an elastic body that is interposed between the ring body and the outer peripheral surface.

Owner:JTEKT CORP

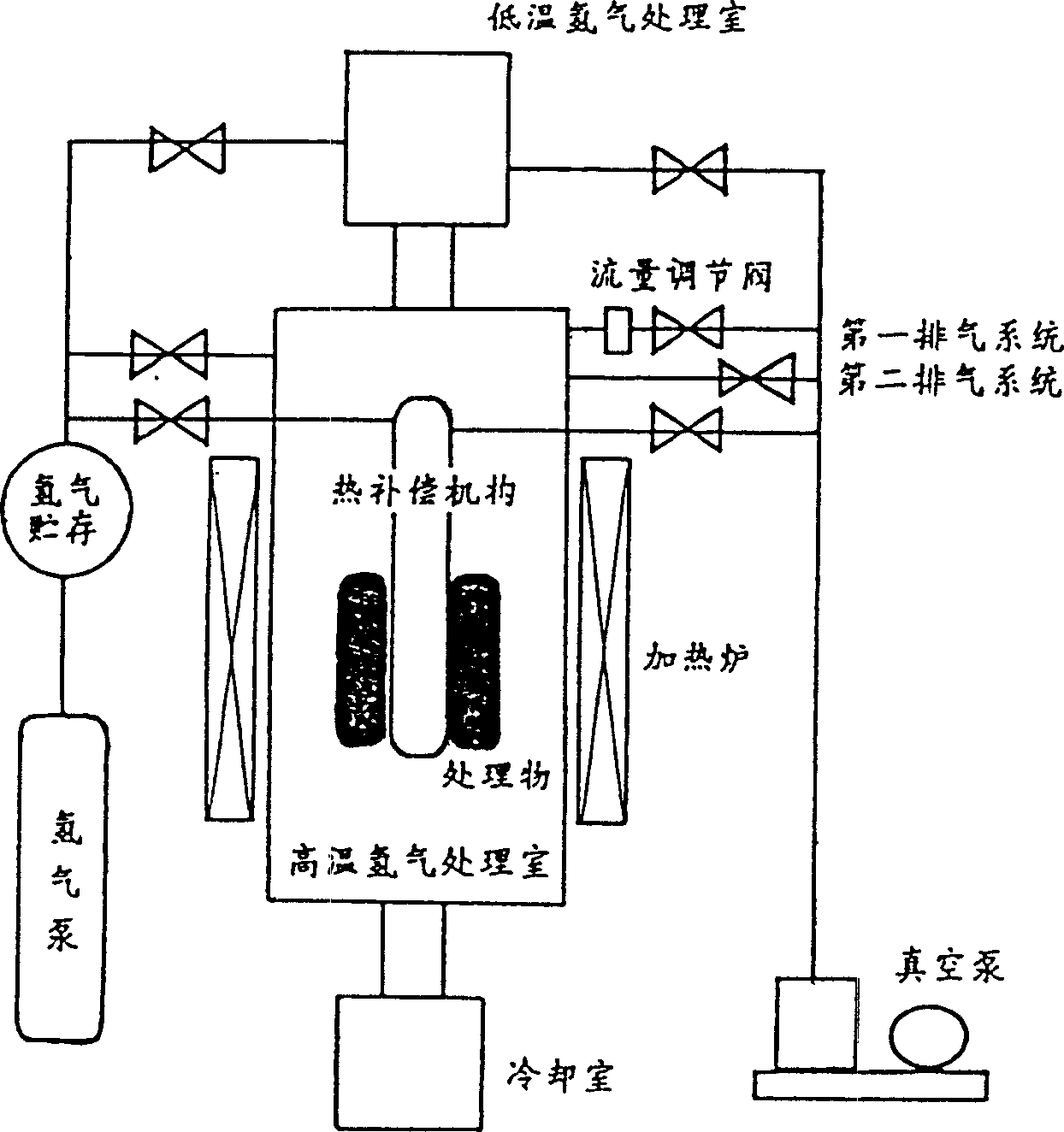

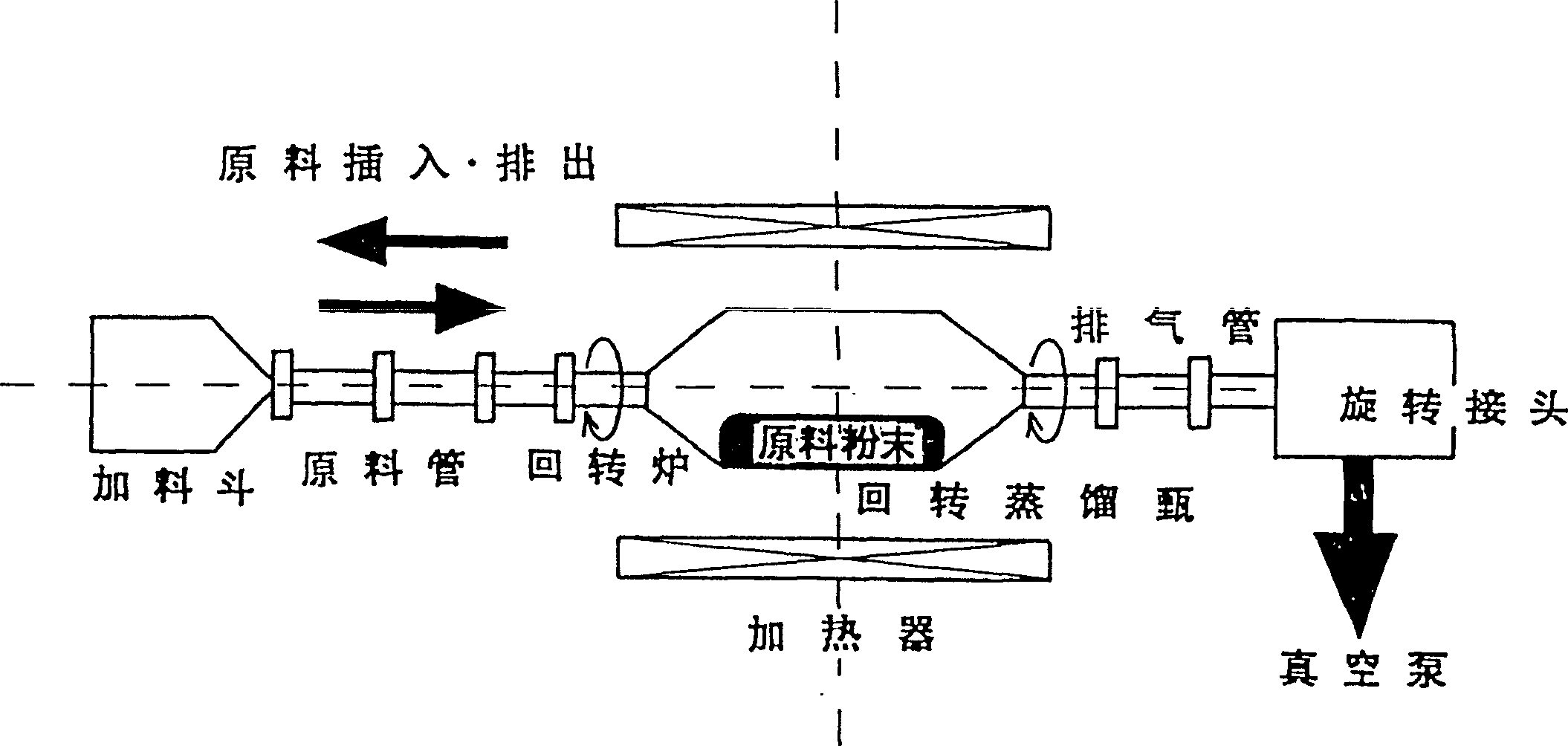

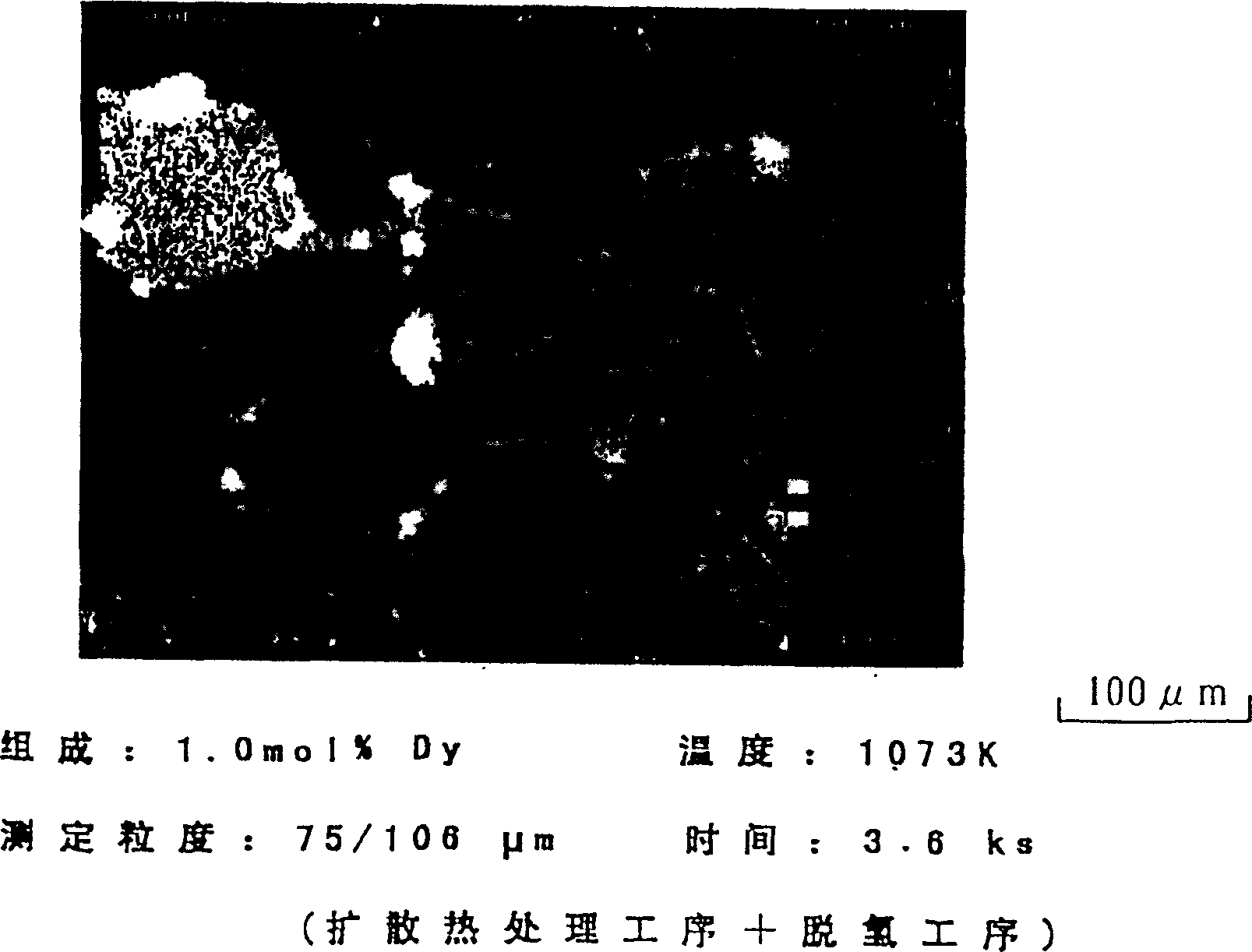

Manufacture and raw material powder of anisotropic magnetic powder and plastics magnet

InactiveCN1198291CInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementDehydrogenation

The invention relates to a method for producing anisotropic magnetic powder capable of obtaining plastic magnets with excellent permanent demagnetization rate. The manufacture method of the anisotropic magnetic powder of the present invention is, carry out low temperature hydrogenation process to RFeB series material (R: rare earth element), high temperature hydrogenation process and the 1st degassing process, manufacture its hydride RFeBHx powder, for this by RFeBHx Powder (raw material powder of anisotropic magnetic powder) is mixed with diffusion powder composed of dysprosium hydride, etc., and the diffusion heat treatment process and dehydrogenation process are performed to obtain anisotropic magnetic powder with excellent coercive force and anisotropy rate. Anisotropic magnetic powder. Plastic magnets made of this anisotropic magnetic powder have excellent permanent demagnetization rate.

Owner:AICHI STEEL

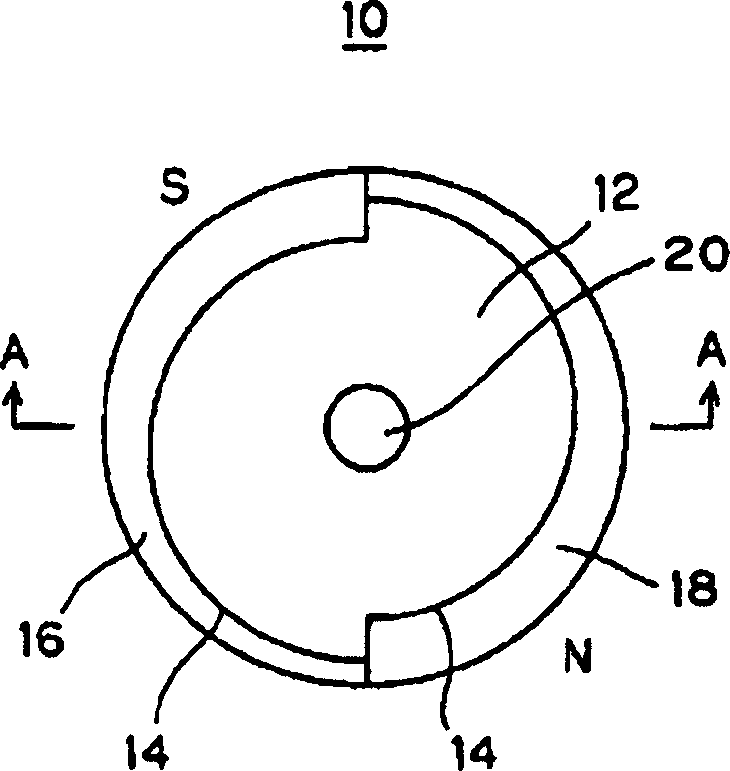

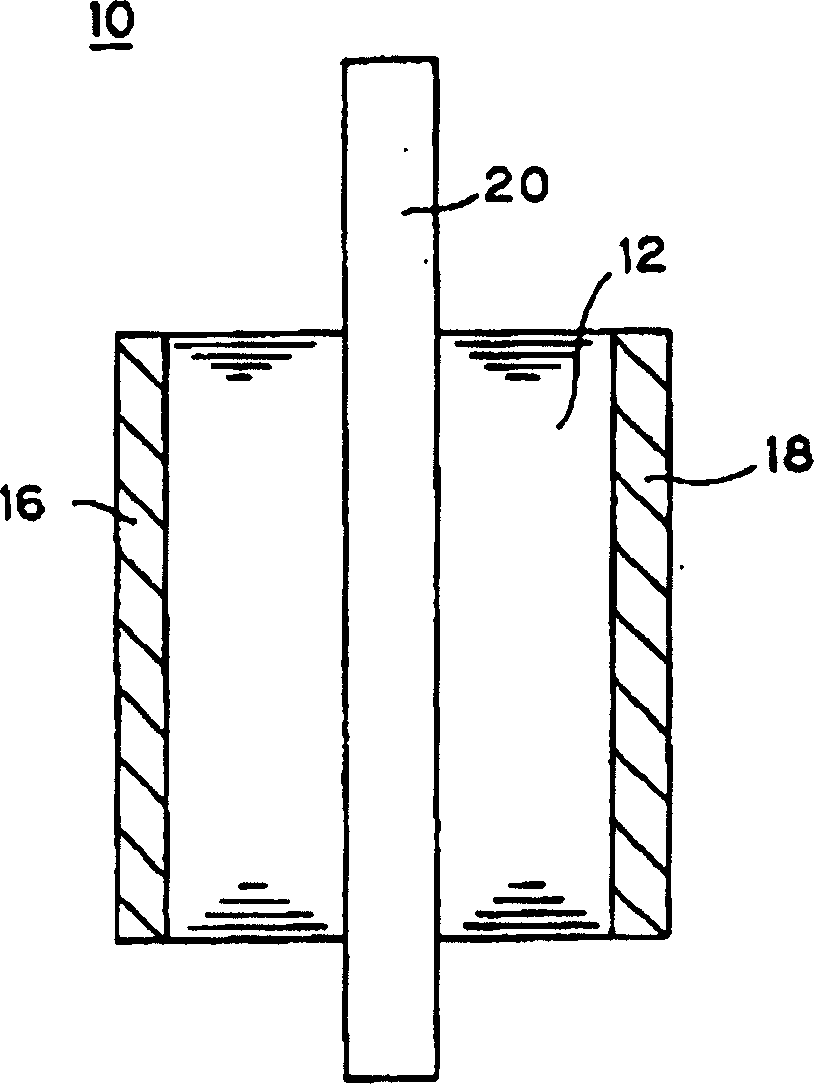

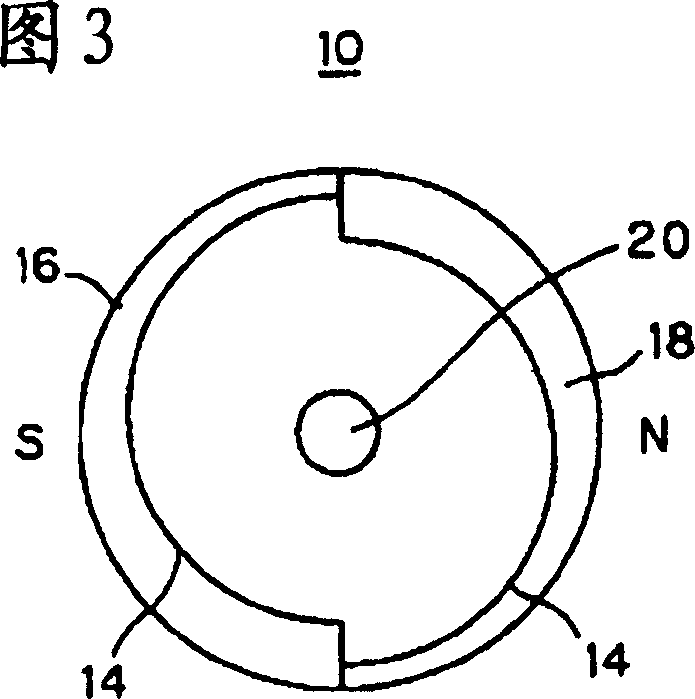

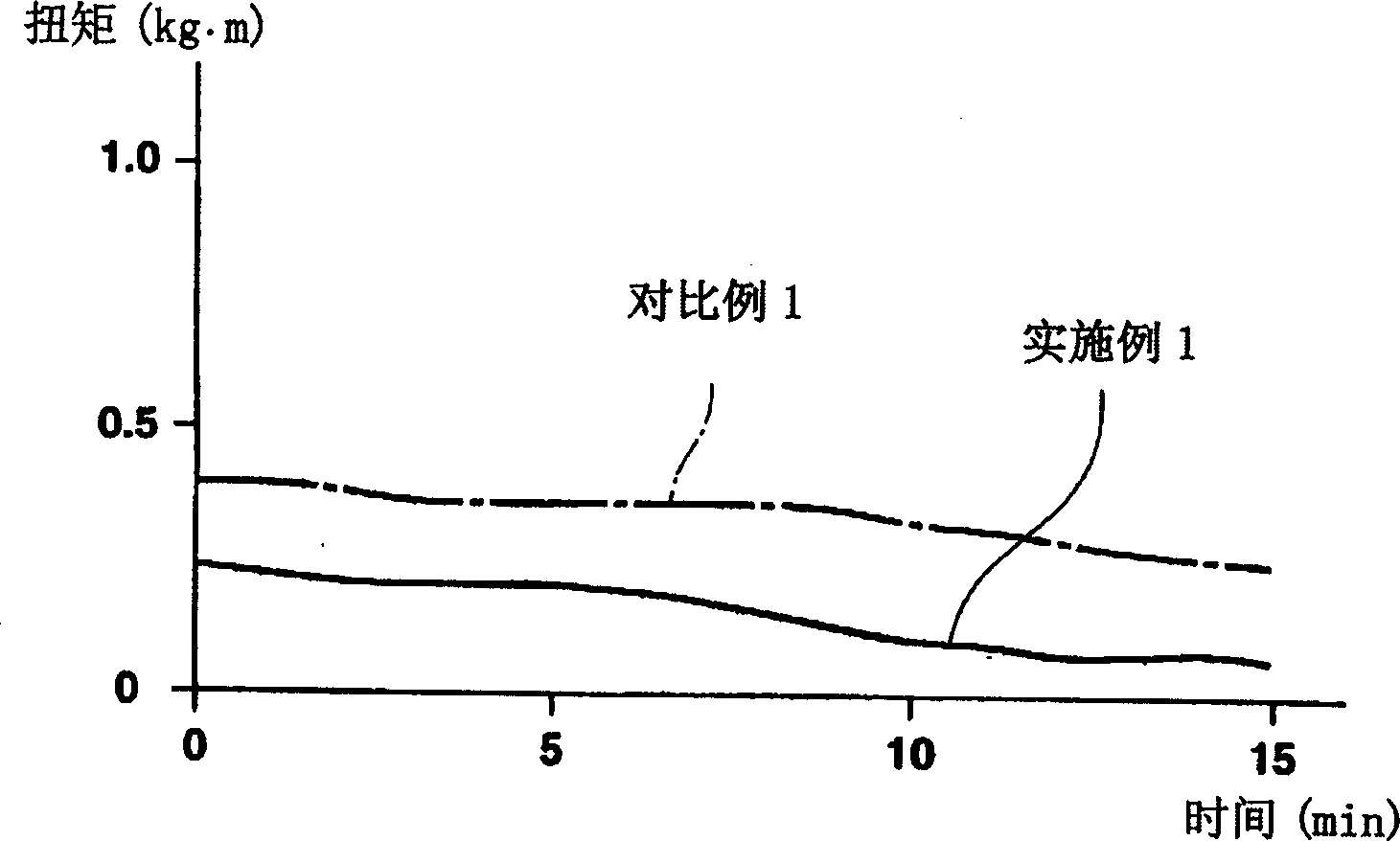

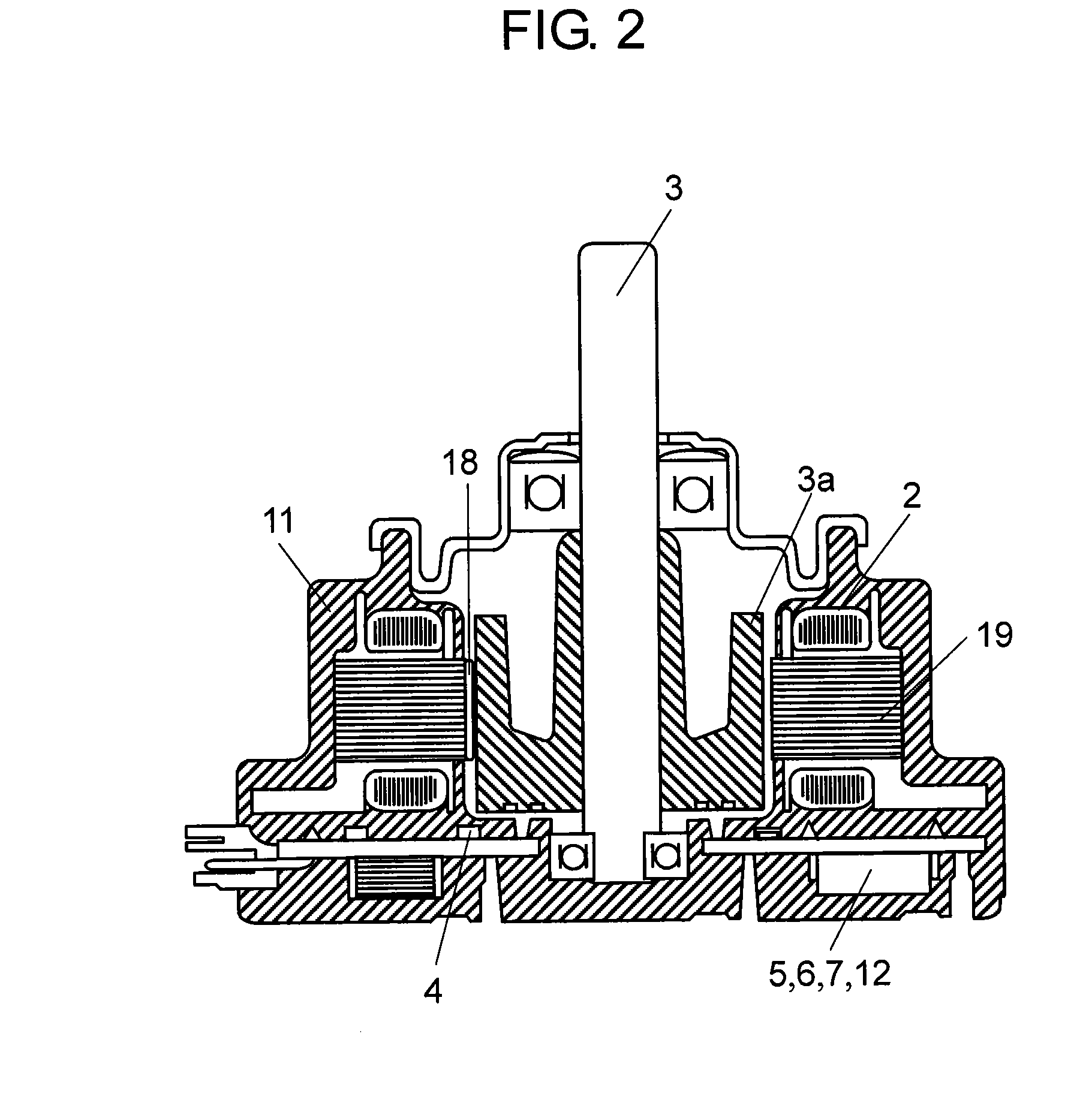

Motor rotor

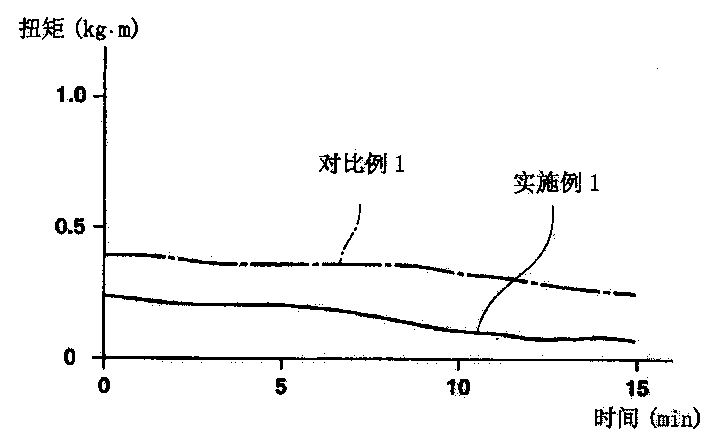

InactiveCN1681184AIncrease torqueEasy to startIncision instrumentsMagnetic circuit rotating partsPlastic magnetElectric motor

The present invention is to provide a rotor of a motor capable of facilitating self-start and assembling work. A plastic magnet 16 magnetized with the S pole on the outer circumferential side of a rotor 10 and a plastic magnet 18 magnetized with the N pole on the outer circumferential side of the rotor 10 are provided alternately on the outer circumferential surface of a rotor core 12. The plastic magnets 16, 18 of the poles have spiral cross-sectional shapes which are made eccentric on the inner circumferential side, thus enhancing starting torque.

Owner:NIDEC SHIBAURA CORP

Composition for synthetic resin composition and formed resin magnet

InactiveCN1469906AImprove featuresImprove plasticityInorganic material magnetismElectrographic process apparatusThermoplasticShell molding

A composition for synthetic resin magnets (such as magnet rollers for electrophotography process) which is composed of a resin binder and a magnetic powder mixed and dispersed therein. The resin compound has improved melt flow rate because the binder contains a thermoplastic and an aliphatic polyamide. Owing to its improved melt flow rate, the resin compound can be incorporated with a large amount of magnetic powder without deterioration in moldability. Thus the resulting plastic magnet has a strong magnetic force. In addition, the composition for synthetic resin magnets may be incorporated with a hindered phenol antioxidant, so that it is molded at a higher temperature (120-180 DEG C.) than usual to achieve the same object as mentioned above.

Owner:BRIDGESTONE CORP

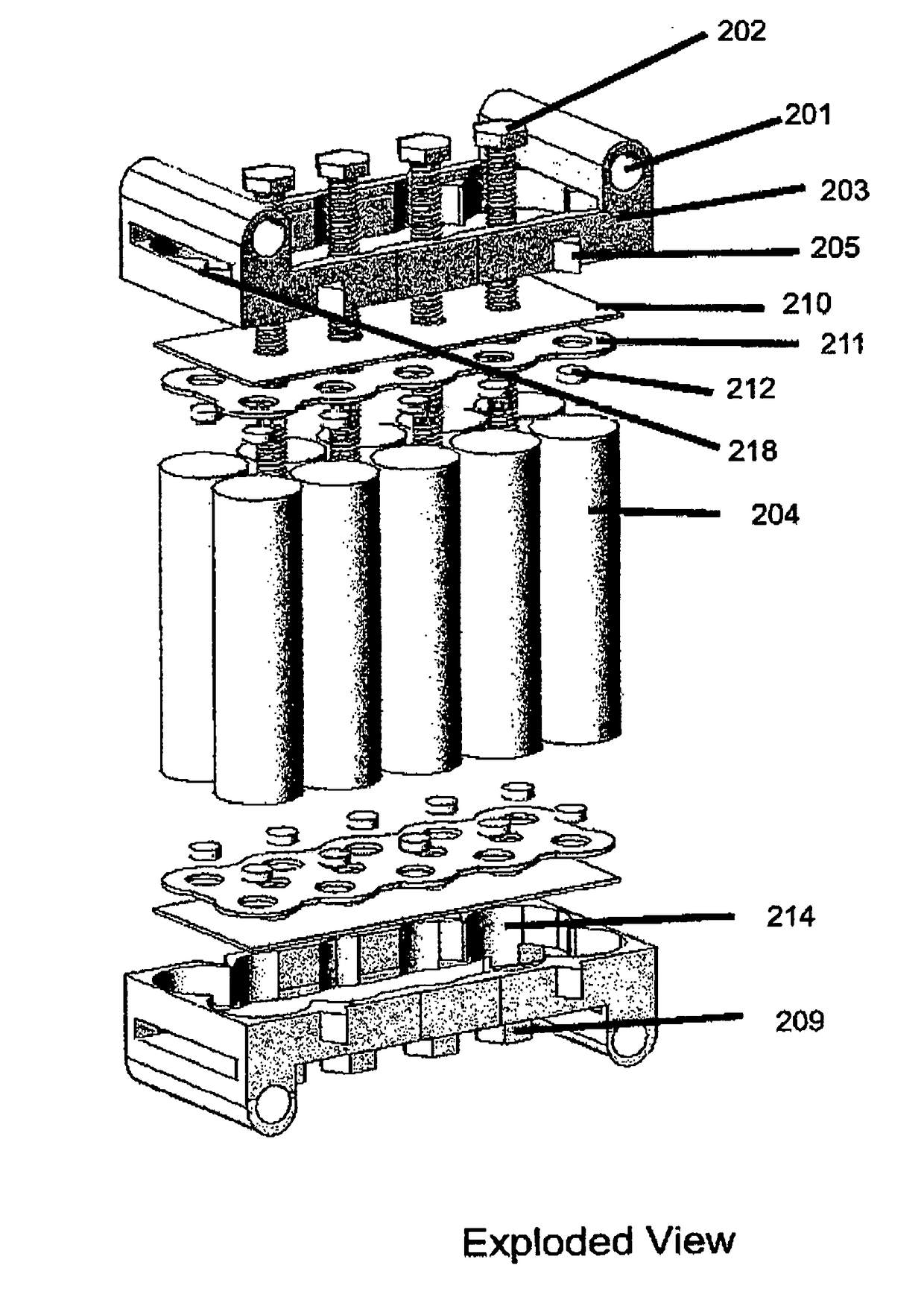

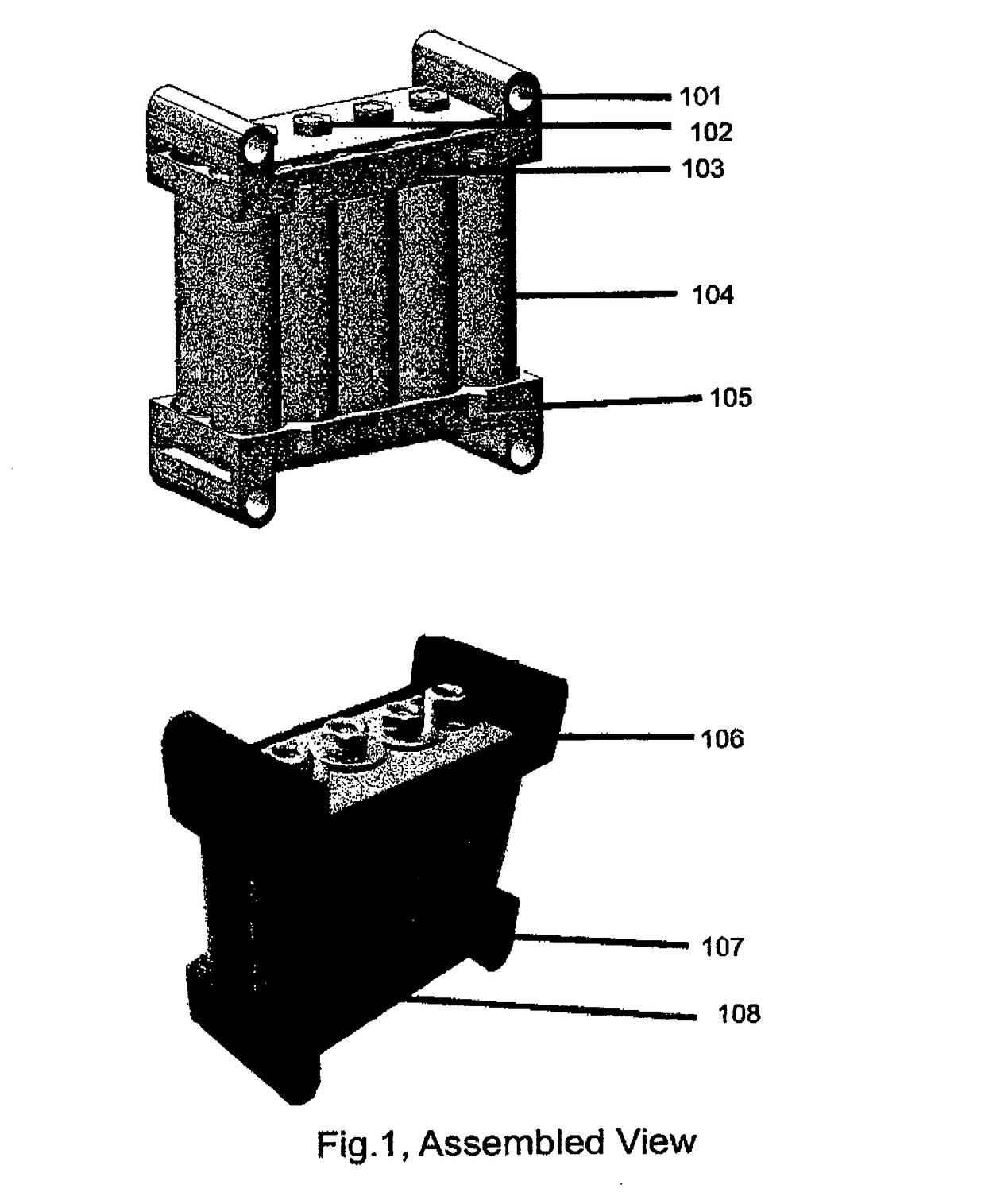

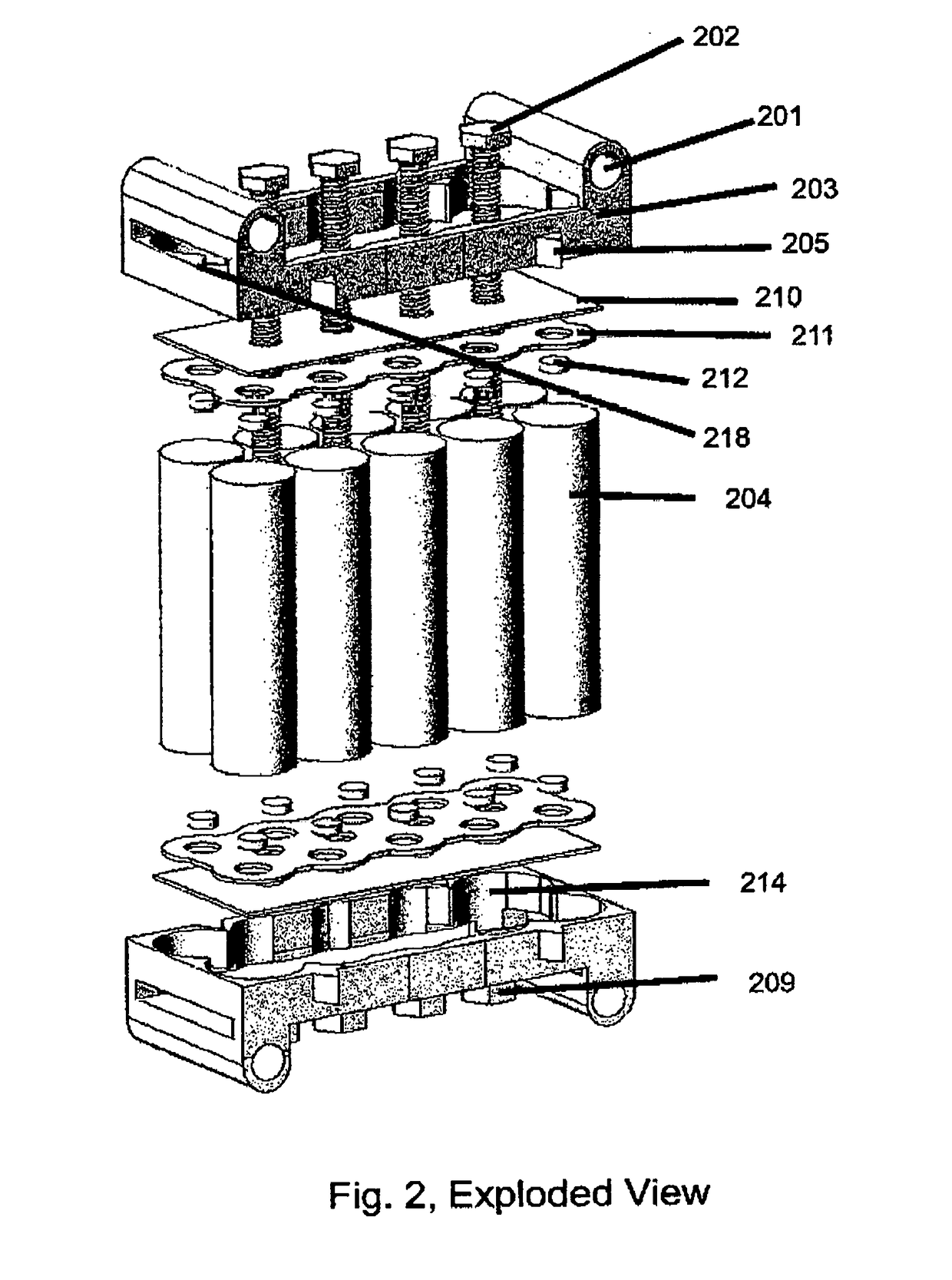

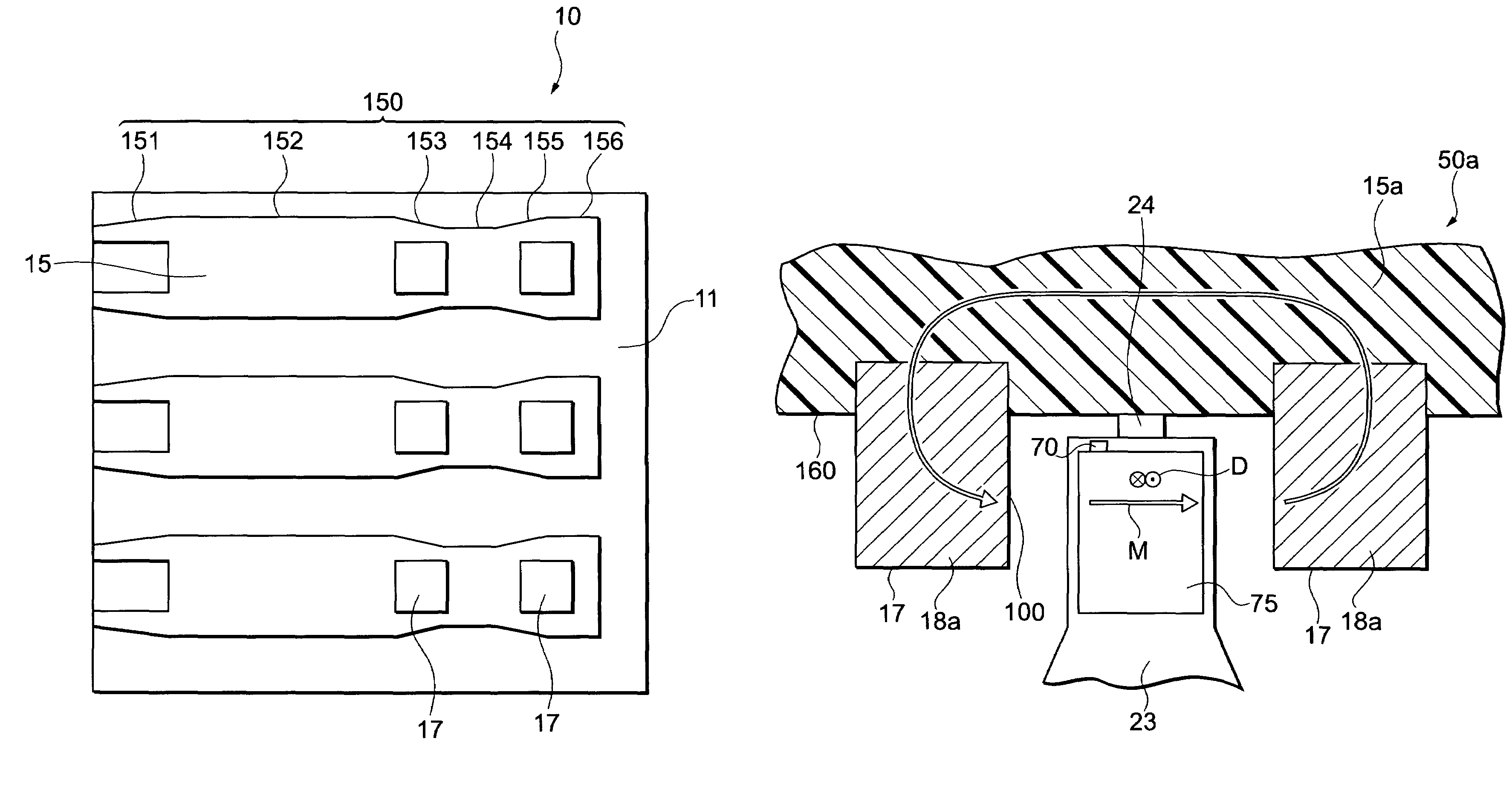

Means for Assembling Cylindrical Batteries into a Modular and Rebuildable Battery Pack

InactiveUS20180123096A1Massive connectivityCell component detailsBatteriesParallel plateElectrical connection

Lithium batteries of this capacity are typically built of cells that are connected with spot welding. Should one cell fail an entire battery must be discarded. The design of these “Blocs” allows cells to be replaced. The individually replaceable cells allow the battery to be repaired, rebuilt and upgraded unlike spot welded batteries.The unique open top case design allows the Blocs can be assembled in any configuration. Connections between Blocs are made with conductive plates which can be dissasembled and provide structural support.The magnets used form button tops for the cells and allow the Blocs to be “snapped” together,The non-conductive bolts provice compressive force making good electrical connection between the cell, magnets, and rigid parallel plates.The plastic magnet holders keep the magnets from drifting and isolate the negative charged case from the positive terminal.Finally the standoffs provide a means for mounting the Blocs to a flat surface or to bolt together using threaded rod to make a battery needing no extra structural support.

Owner:MCCARTY SHAWN ALLAN

Magnetic module

InactiveCN103515056AChange shapeChange sizeCoupling for high frequencyTransformers/inductances coils/windings/connectionsPlastic materialsPlastic magnet

A magnetic module comprises a plastic magnet and a coil wound on the plastic magnet. The plastic magnet is formed by adding magnetic material into plastic material. The shape of the magnetic module can be changed by changing the shape of the plastic material after undergoing forming so that the shape of the magnetic module can be changed easily, and finally the magnetic module required by a product is obtained.

Owner:LUXSHARE PRECISION IND SHENZHEN

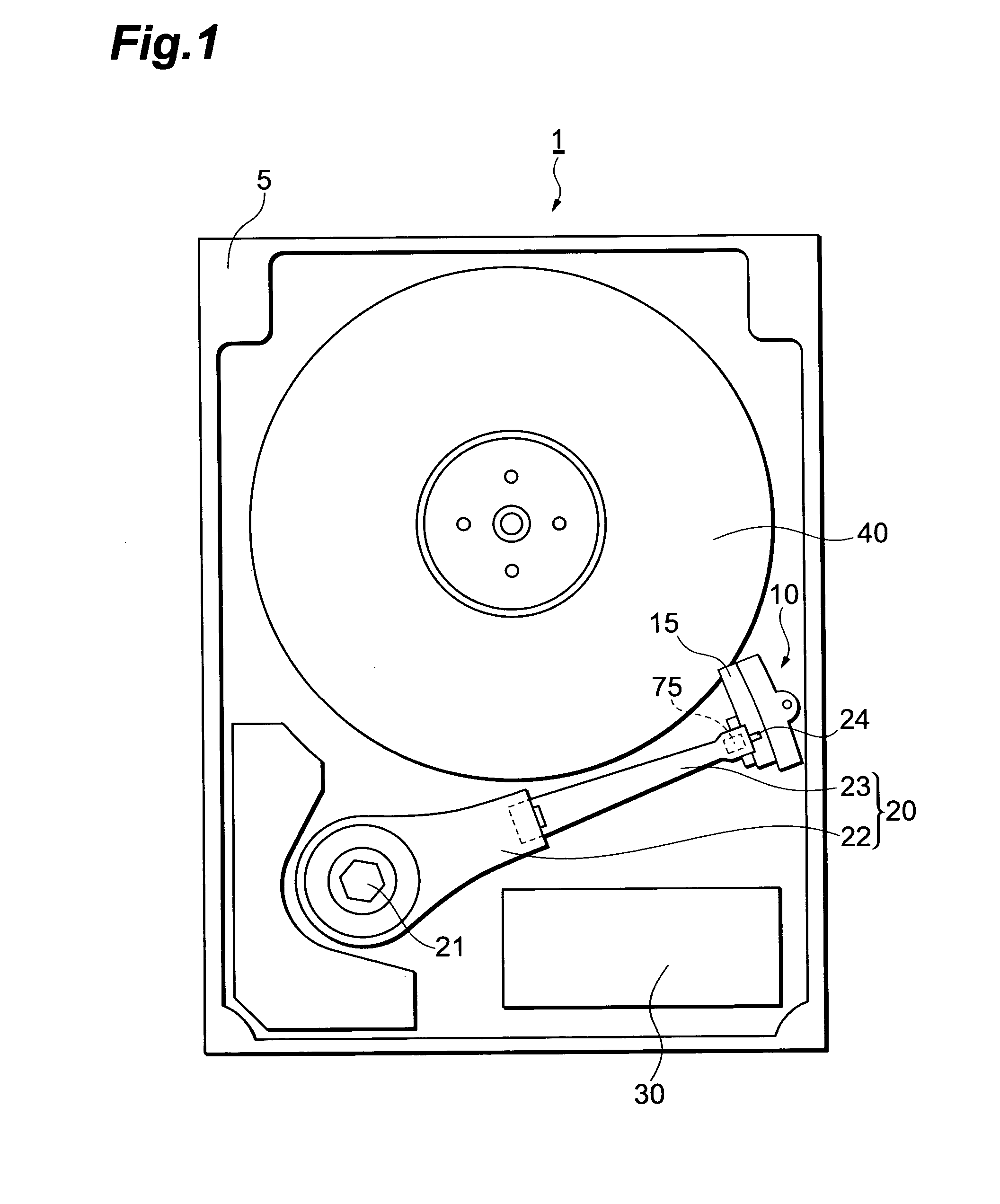

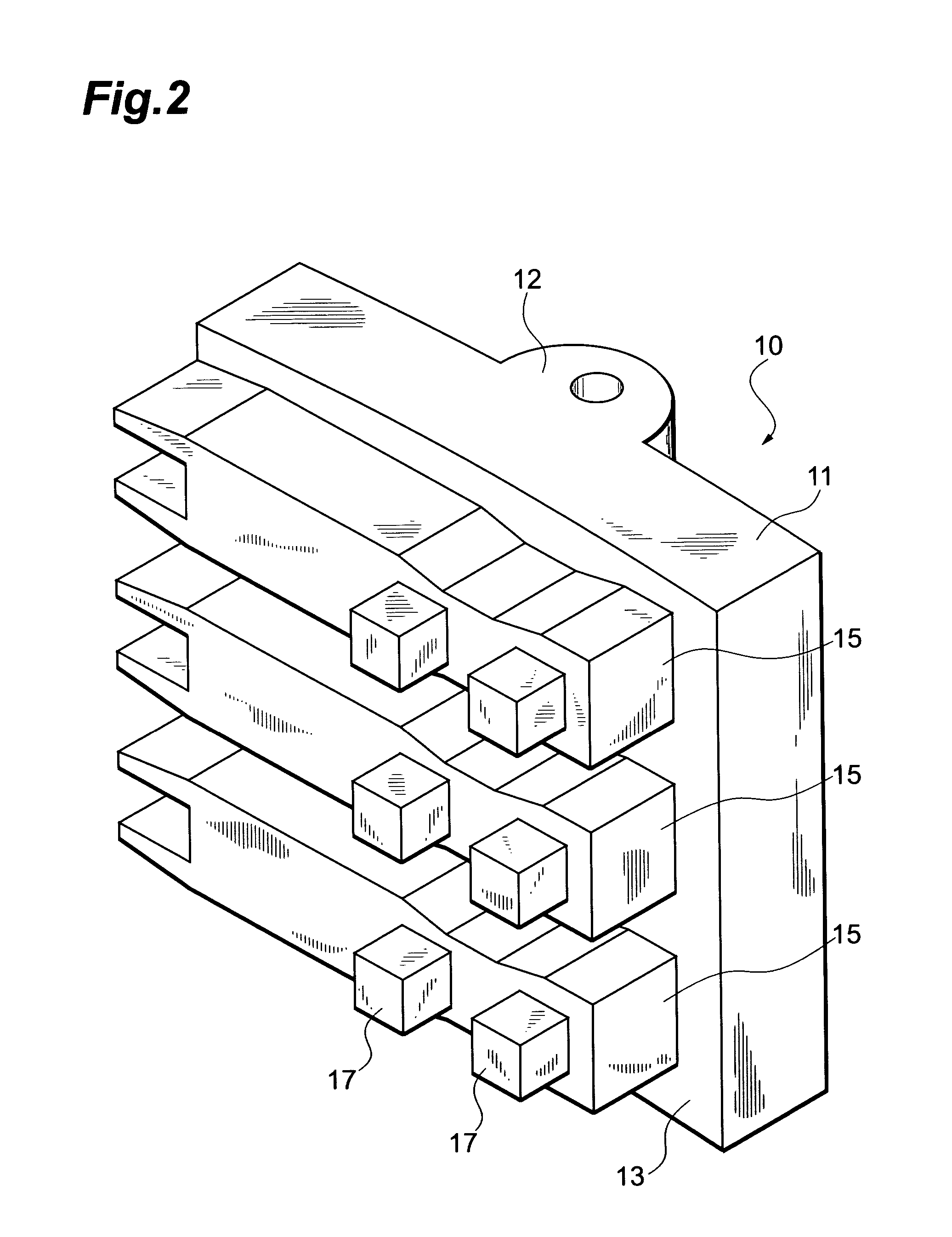

Magnetic recording apparatus with head arm holding part

ActiveUS7474509B2Change the output characteristicsReduced strengthDisposition/mounting of recording headsRecord information storagePlastic magnetMagnet

A magnetic recording apparatus comprises a magnetic disk; a magnetic head, including a magnetoresistive device, for reading information from the magnetic disk; an arm attached to the magnetic head and swings so as to load and unload the magnetic head to or from the magnetic disk; a magnetic field applying part disposed close to the magnetic disk, made of a magnetic material, and formed with a groove for surrounding the magnetic head; and a holding part for holding the arm such that the unloaded magnetic head stays at a position surrounded by the groove; whereas the magnetic material contains a plastic magnet.

Owner:TDK CORPARATION

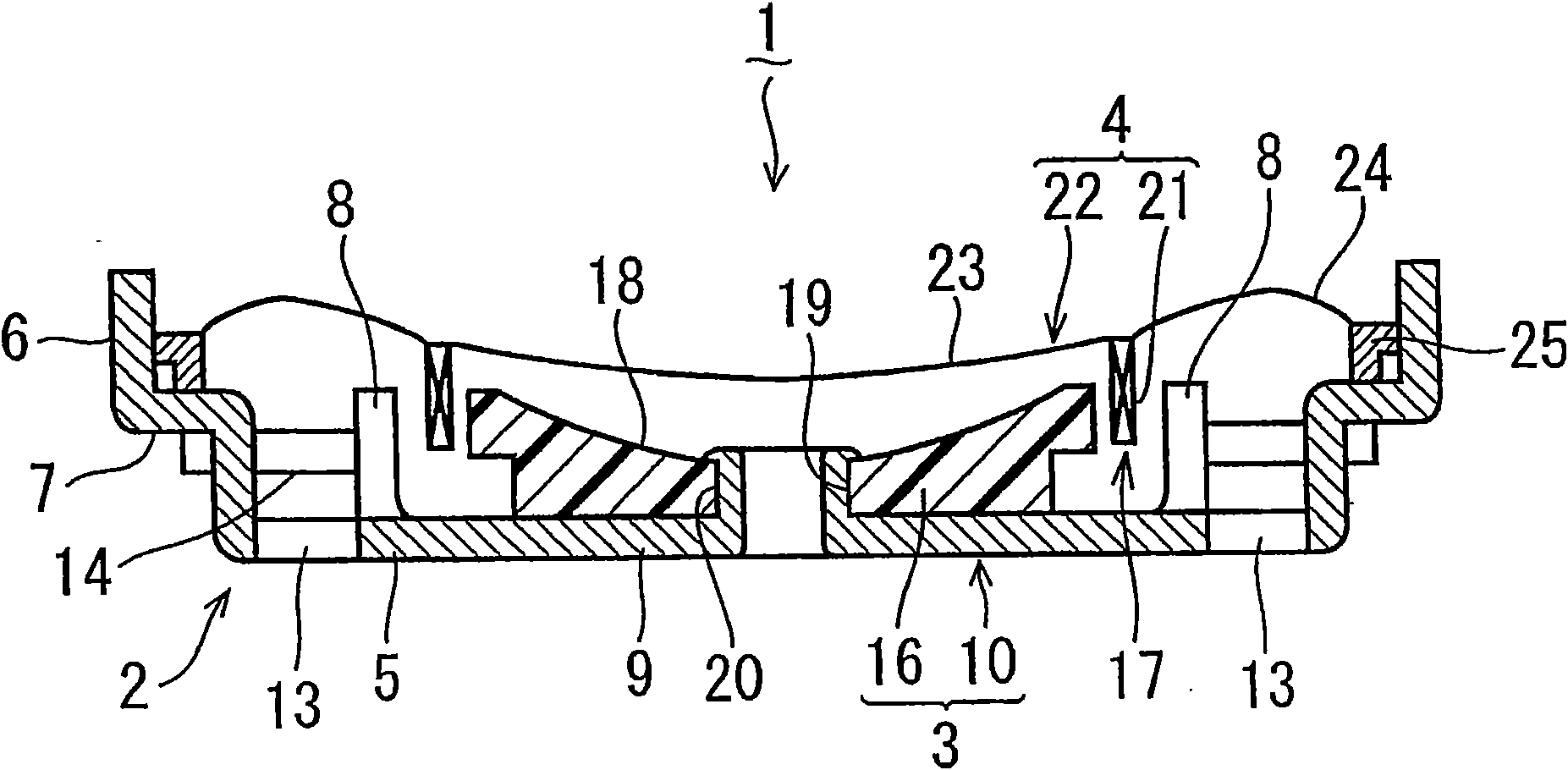

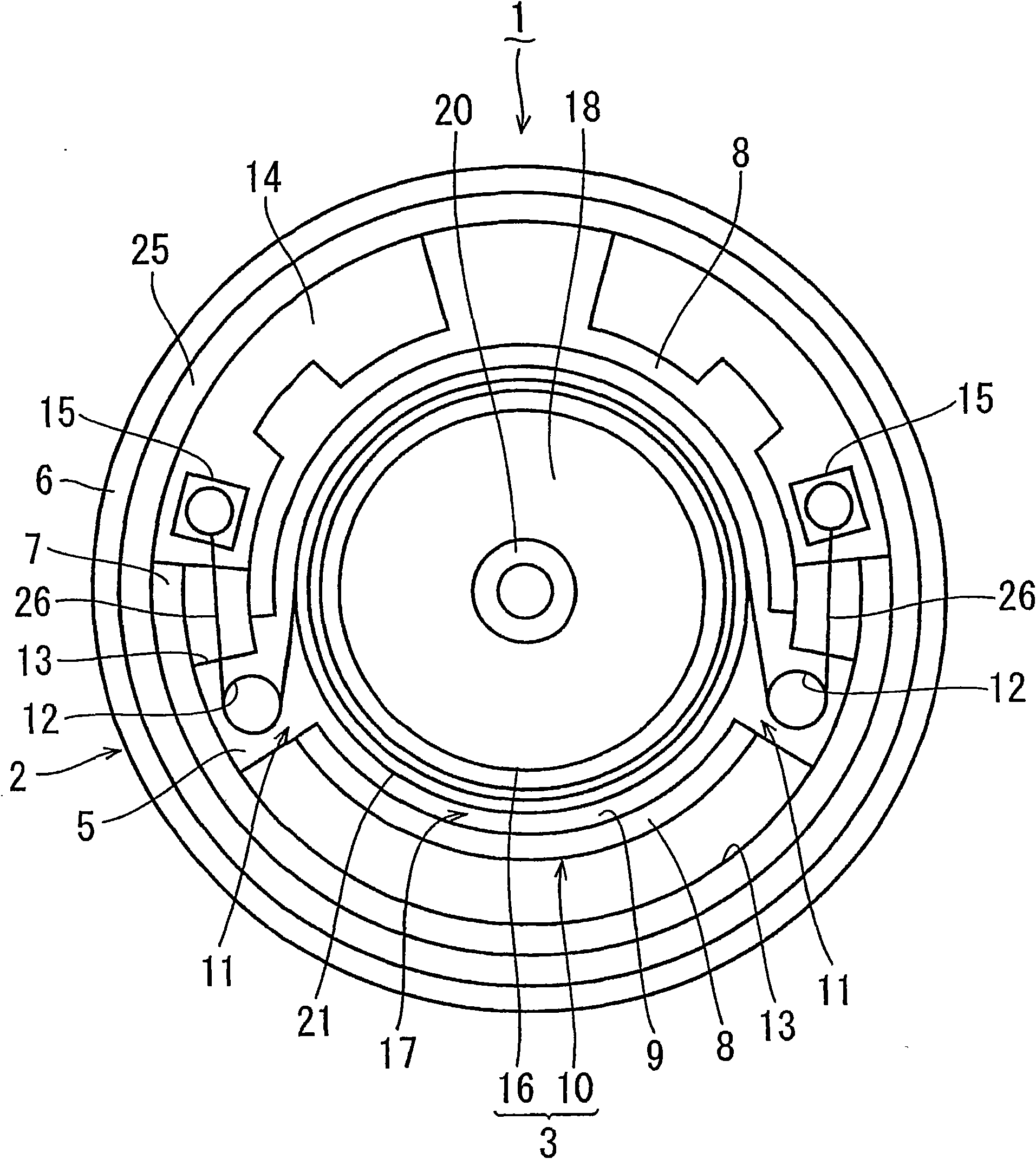

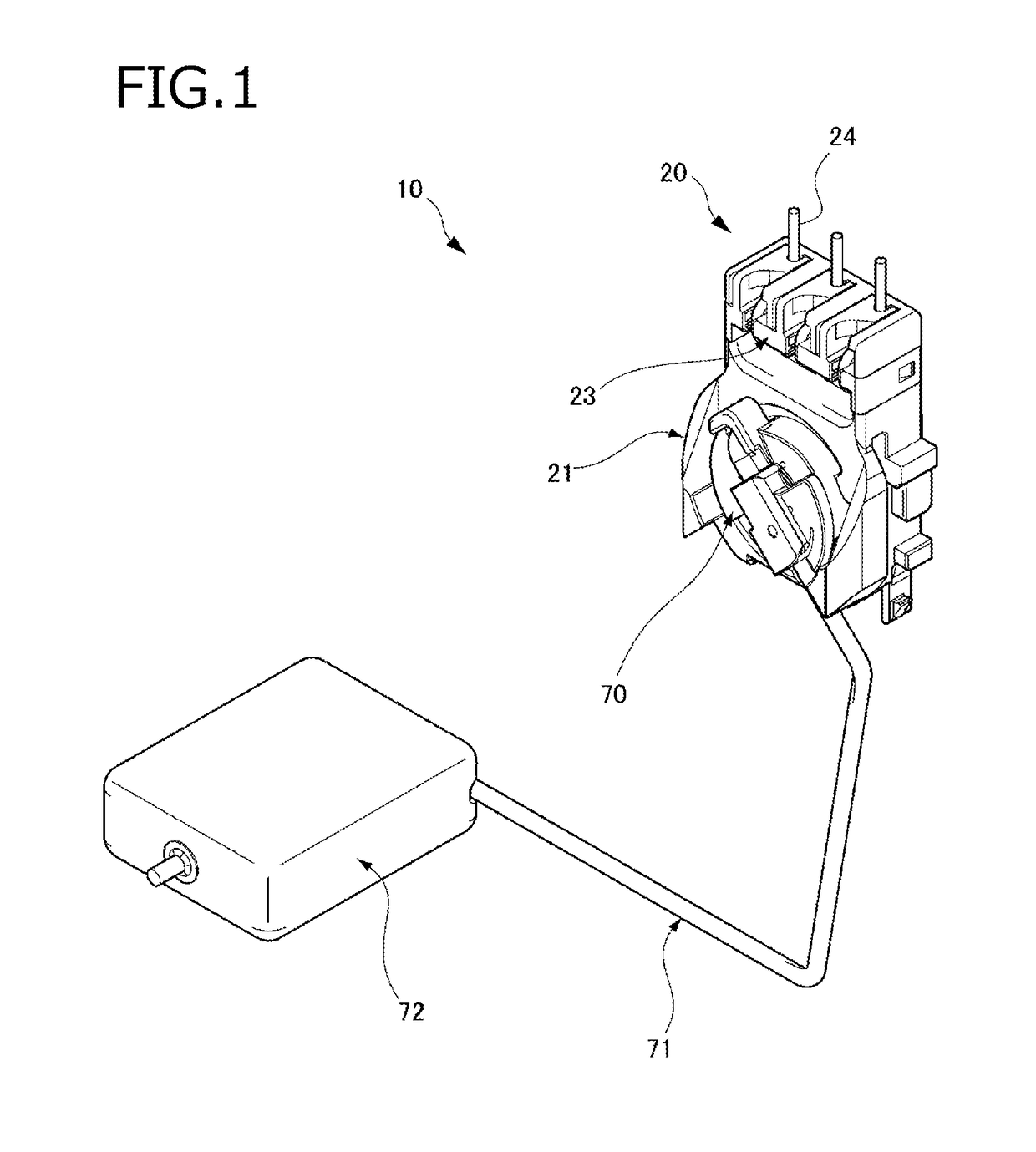

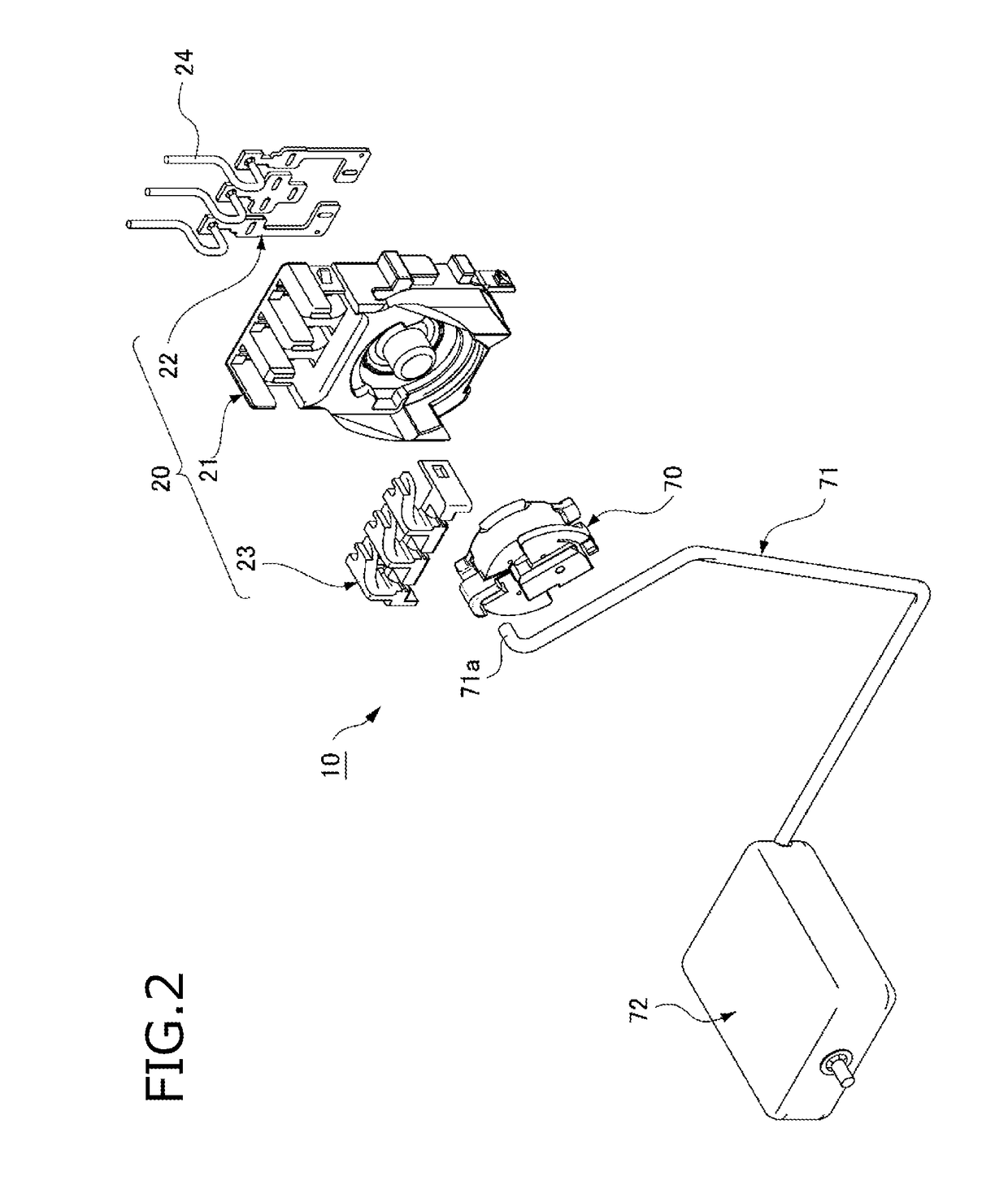

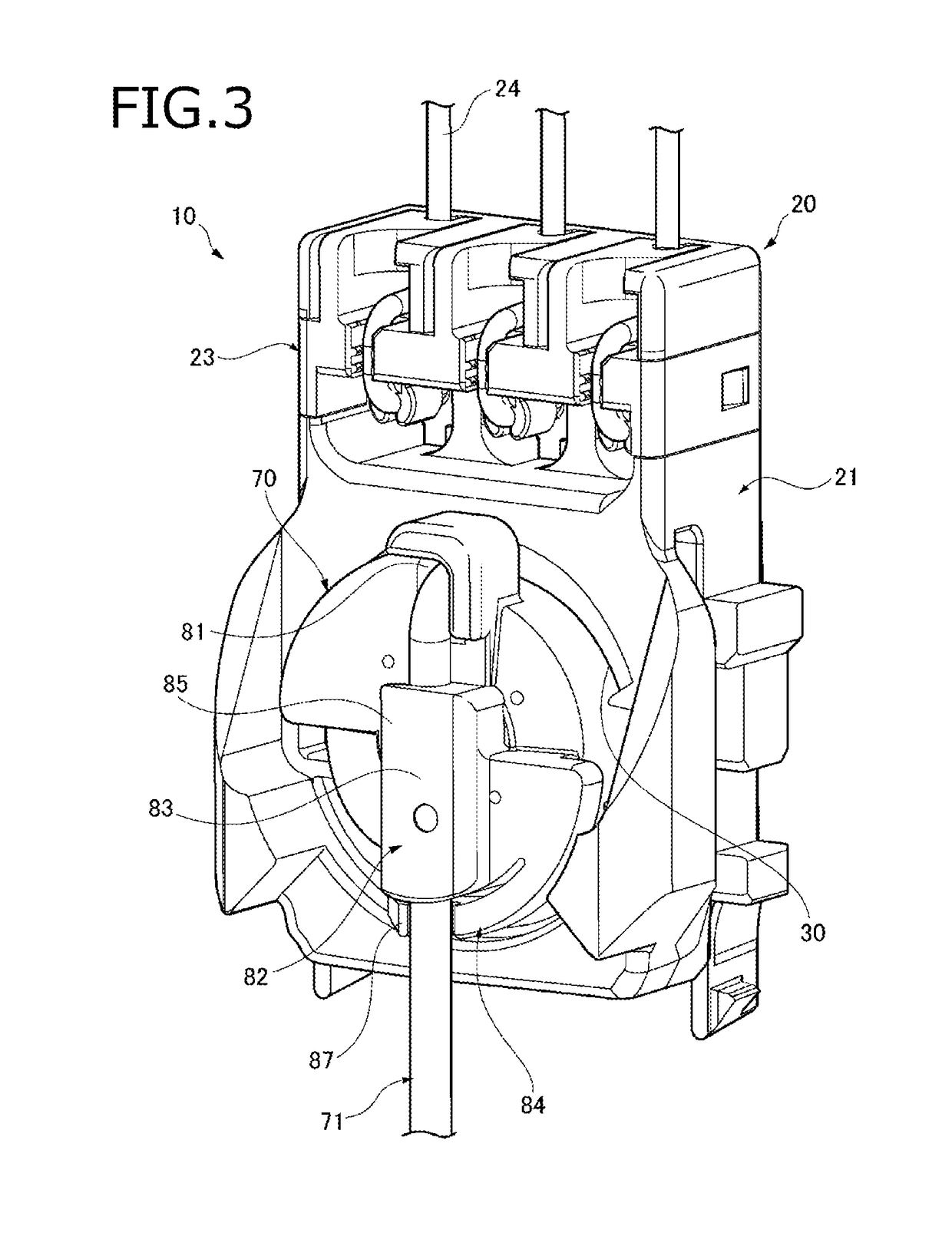

Speaker

InactiveCN101600137AEase of mass productionSufficient amplitudeElectrical transducersEngineeringPlastic magnet

The invention provides a speaker comprising: a magnetic circuit 3; a vibration system 4 in which a diaphragm 22 is attached to a voice coil 21; and a frame 2 which supports the magnetic circuit 3 and the vibration system 4. The voice coil 21 is placed in a magnetic gap 17. By taking advantage of the characteristics of a plastic magnet that it can be easily processed into a desired shape, the magnetic circuit 3 is configured by: a plastic magnet 16 having a T-like section shape; and a yoke 10 which is continuously disposed in a bottom portion side and periphery of the plastic magnet 16. The number of components of the magnetic circuit, which conventionally has the three-piece structure, is reduced, so that the mass productivity of a small and thin speaker can be enhanced.

Owner:HOSIDEN CORP

Magnetic encoder, and production method therefor

InactiveCN105556249AImprove reliabilityLow priceConverting sensor output electrically/magneticallyEngineeringInjection moulding

The invention provides a magnetic encoder, and a production method therefore. The magnetic encoder is produced by: applying, during insert moulding, an adhesive agent in a hardened state or a cured state so as to not be washed away from a fixed member by a molten substance of a plastic magnet material, said adhesive agent being capable of having a coating state thereof controlled by way of heating; removing from a die, after completion of the insertion moulding, a moulded article for each slinger; and heating said adhesive agent, after completion of injection moulding, to induce adhesion and establish an adhesive bond between a magnet part and the fixed member.

Owner:NSK LTD

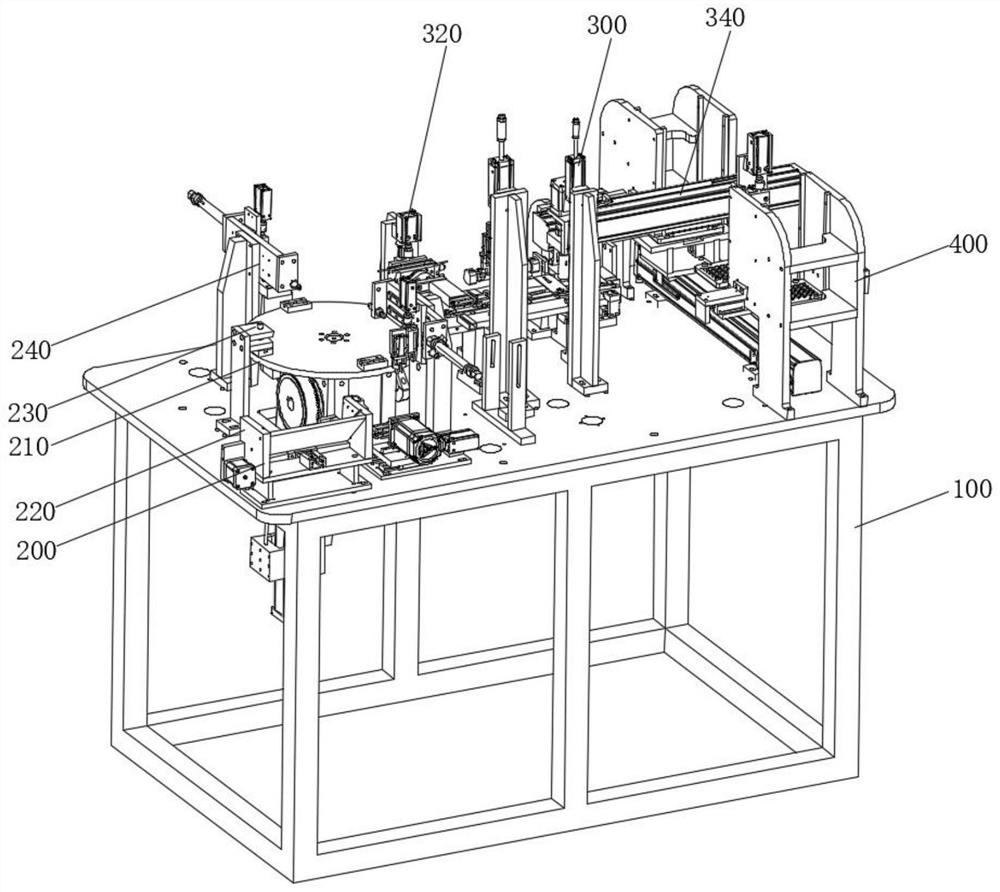

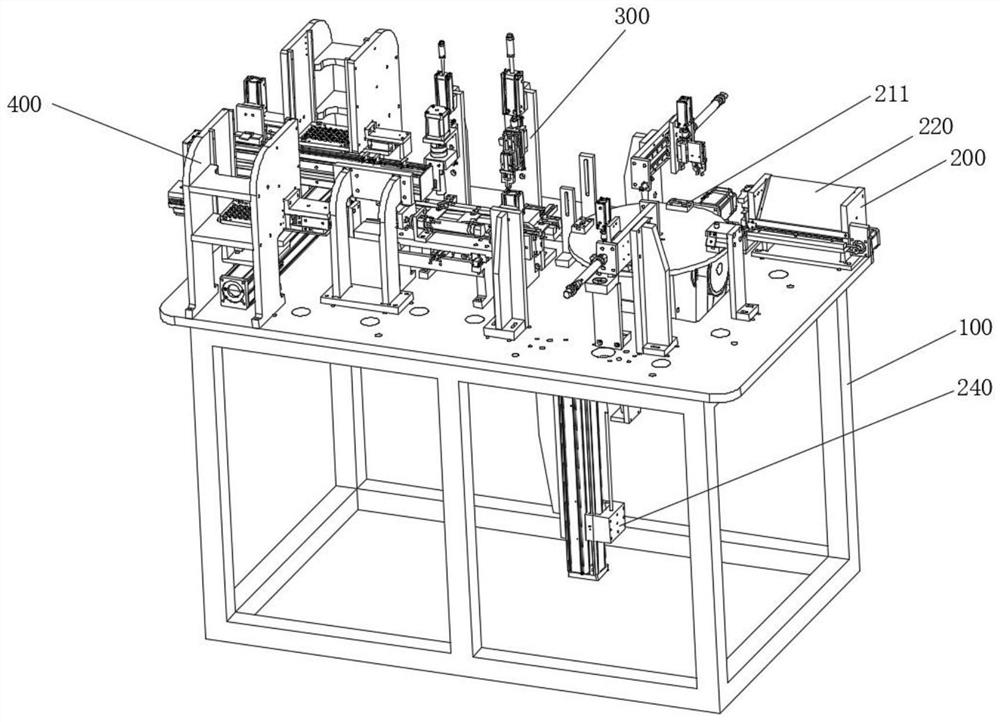

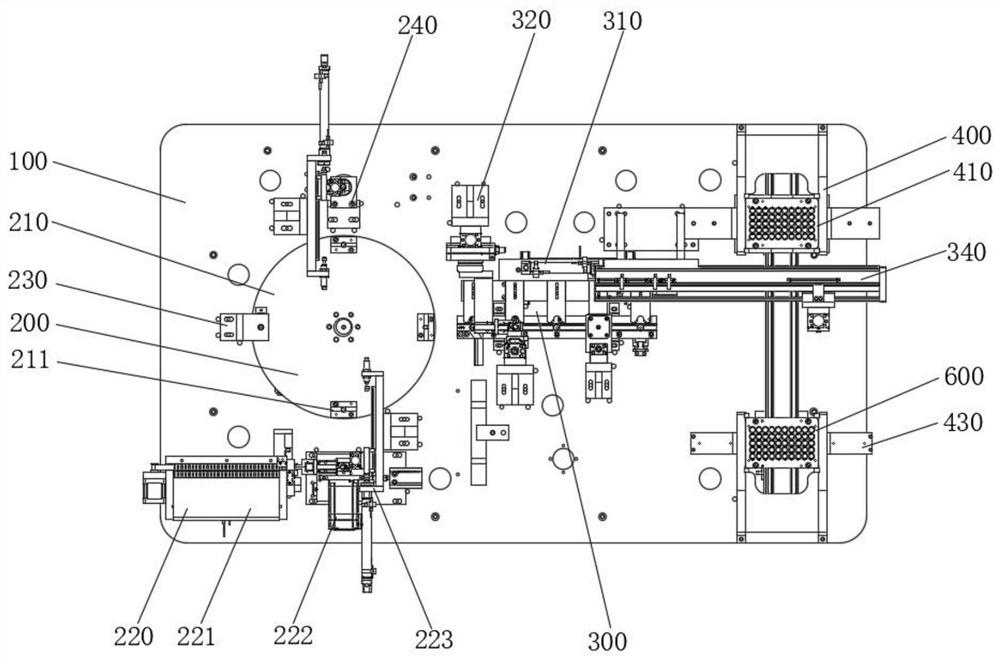

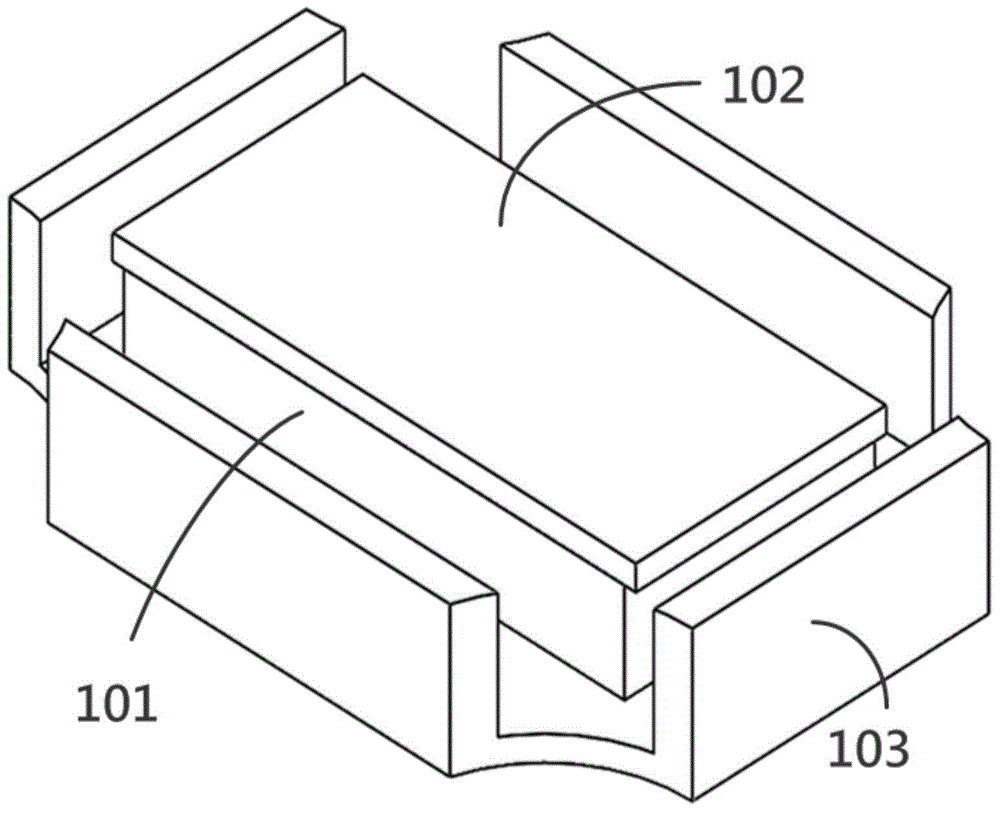

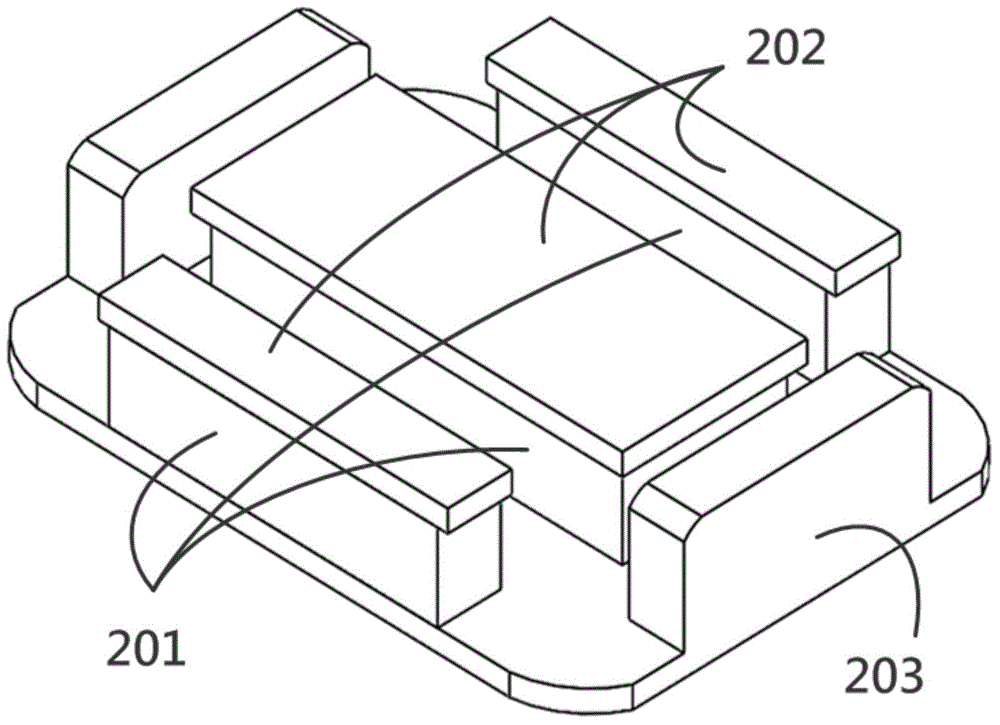

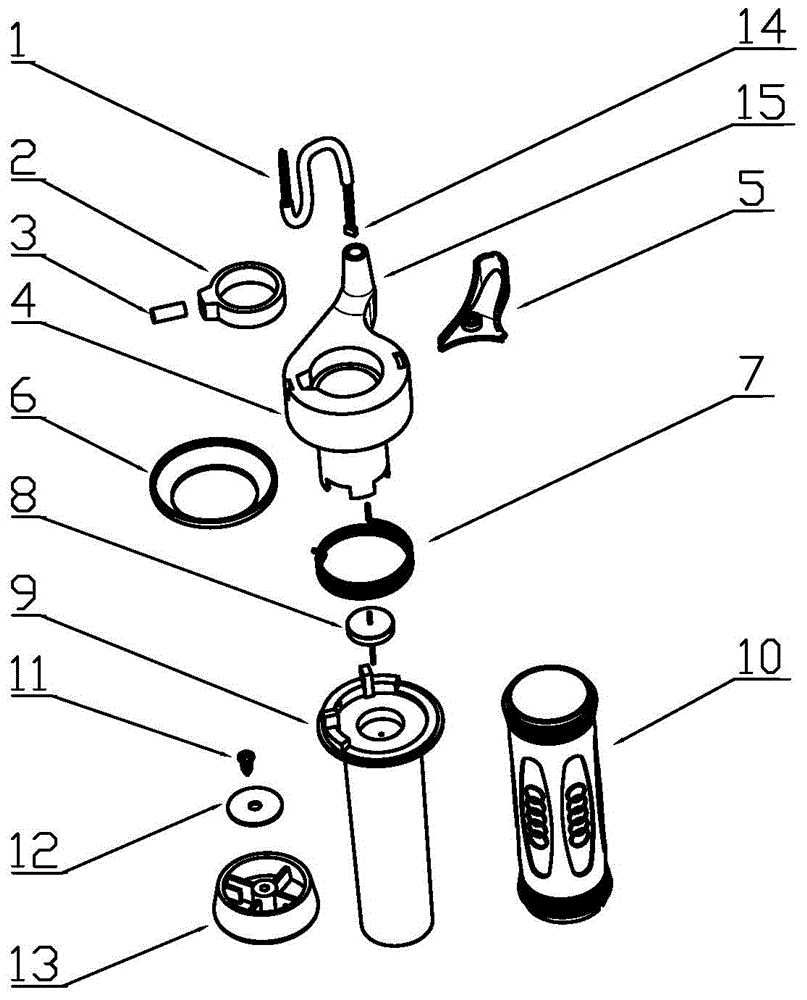

Buzzer automatic assembling machine

ActiveCN113894537ASimple structureRealize pure mechanical processingAssembly machinesPlastic magnetMachining

The invention relates to the field of buzzer automation, in particular to a buzzer automatic assembling machine. The buzzer automatic assembling machine comprises a workbench, and the workbench is provided with a part feeding module, an assembling module and a material receiving module. The buzzer automatic assembling machine is specially used for assembling novel buzzers, magnetic rings are placed and stored in a material bin mode during feeding, the storage quantity is large, during use, a stop block air cylinder drives a stop block to achieve automatic material falling and feeding, the operation is simple, convenient and time-saving, frequent material changing is not needed, synchronous belt material conveying and feeding are achieved, the automation degree is greatly improved, inner supporting type clamping jaws are adopted for taking materials, separation of plastic magnets is achieved through cooperation with magnetic rings with steps, through combining of a plate placing mechanism, a plate conveying mechanism and a plate taking mechanism, the material receiving module achieves automatic material receiving, coils, cover plates and connector lug assembling parts only need to be additionally arranged on the upper portions of buzzer semi-finished products and then pressed so that assembling of the whole buzzers can be achieved, the structure is simple, pure machining can be achieved, existing manual dispensing assembling is replaced, time and labor are saved, and the quality of produced products is higher.

Owner:CHANGZHOU FHD ELECTRONICS CO LTD

Magnetic system and loudspeaker monomer and loudspeaker module applying same

InactiveCN104469609AReduced RF interferenceNot easy to intrudeTransducer circuitsComputer moduleEngineering

The invention relates to a magnetic system. The magnetic system comprises a magnet set, one or more magnetic conductive carriers and one or more plastic magnets, wherein the magnet set is provided with one or more magnets, the magnetic conductive carriers are arranged at two polar ends of all the magnets in the magnet set, and the plastic magnets are arranged on the surface not provided with the magnetic conductive carriers or the outer side of the surface. In addition, the invention provides a loudspeaker monomer and loudspeaker module applying the magnetic system. The magnetic system can further enhance the magnetic field intensity and increase the sound pressure of a loudspeaker in limited space.

Owner:蔡旭钦

Manual control electronic throttle sensing module

InactiveCN105697155AThe structural assembly is tight and firmImprove reliabilityEngine controllersMachines/enginesElectronic throttleEngineering

The invention discloses a manual control electronic throttle sensing module which comprises a signal wire, a fixing ring, a spool, a spool decorative cover, a spring, a dipolar magnet, a handle protecting tube, a handle outer sleeve, a handle outer cover and a Hall electronic element, wherein the signal wire is welded with the Hall electronic element; the Hall electronic element is arranged aside the dipolar magnet in a noncontact form; the dipolar magnet is formed by integral injection molding of a plastic magnet and an iron shaft; the handle outer cover sleeves the handle protecting tube; the upper end of the dipolar magnet is arranged in the spool; the handle protecting tube and the spool are sleeved through the spring and the spool decorative cover; and a rotary magnetic signal of the dipolar magnet is sensed by the Hall electronic element. The non-contact Hall electronic element is adopted by the manual control electronic throttle sensing module; the opening degree of a throttle is accurately adjusted; the signal output linearity is excellent; the wave amplitude is stable; the oil consumption is reduced; the abrasion line breakage and tight blocking are avoided; the durability of products is increased; the reliability is increased; the manual control electronic throttle sensing module is applied to the products, such as electric vehicles, mopeds and motorcycles.

Owner:SUZHOU JINYING PRECISION MOLD

Plastic magnet precursor, production method for the same, and plastic magnet

InactiveUS7335316B2Improve suppression propertiesQuality improvementInorganic material magnetismInductances/transformers/magnets manufactureConstant compositionShell molding

Owner:MITSUBISHI ELECTRIC CORP

Rotary flow-crossover valve

InactiveCN1508464AOperating means/releasing devices for valvesMultiple way valvesPlastic materialsMagnetic poles

In a rotary flow-path exchanging valve, the magnetic force generated in a pair of main magnetic pole pieces (66) by energization of an electromagnetic solenoid is acted on a multi-pole magnet (71) of a main valve element accommodated within a valve housing (1) so that the main valve element (3) is rotated to exchange a flow-path. The multi-pole magnet (71) is made of a plastic magnet of plastic material mixed with magnetic powder. The main valve element (3) and multi-pole magnet (71) are integrally formed by multiple molding. A pair of main magnetic pole pieces (66) magnetically connected to one polarity of the electromagnetic solenoid (11) are arranged. A pair of auxiliary magnetic pole pieces (70) connected to the other polarity of the electromagnetic solenoid (11) are arranged at positions out of phase from the magnetic pole pieces by 90 DEG . The pair of auxiliary magnetic poles (70) are opposed to portions of the multi-pole magnet (71) having a reverse polarity to that of portions of the multi-pole magnet (71) opposite to the main magnetic poles (66).

Owner:SAGINOMIYA SEISAKUSHO INC

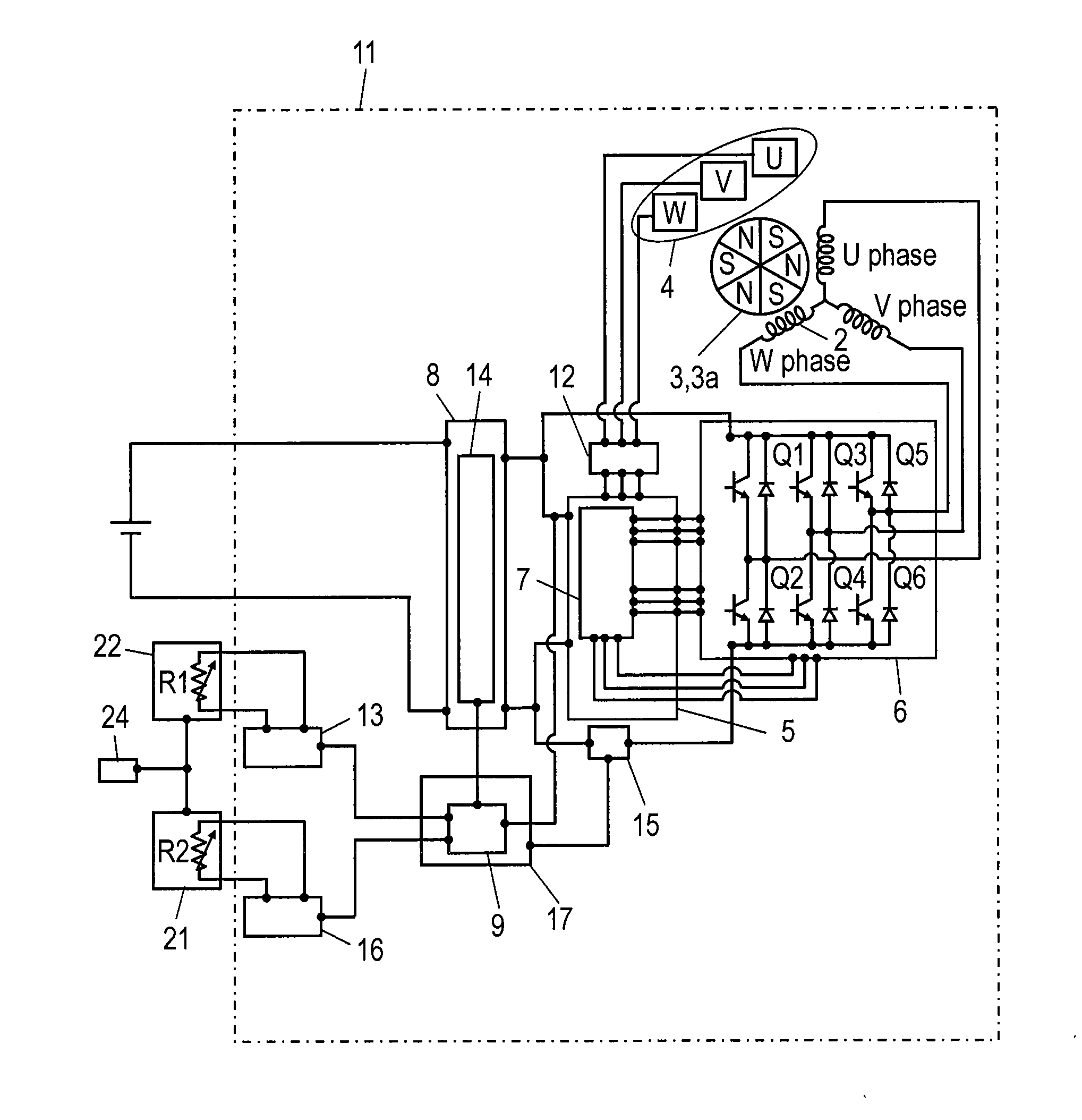

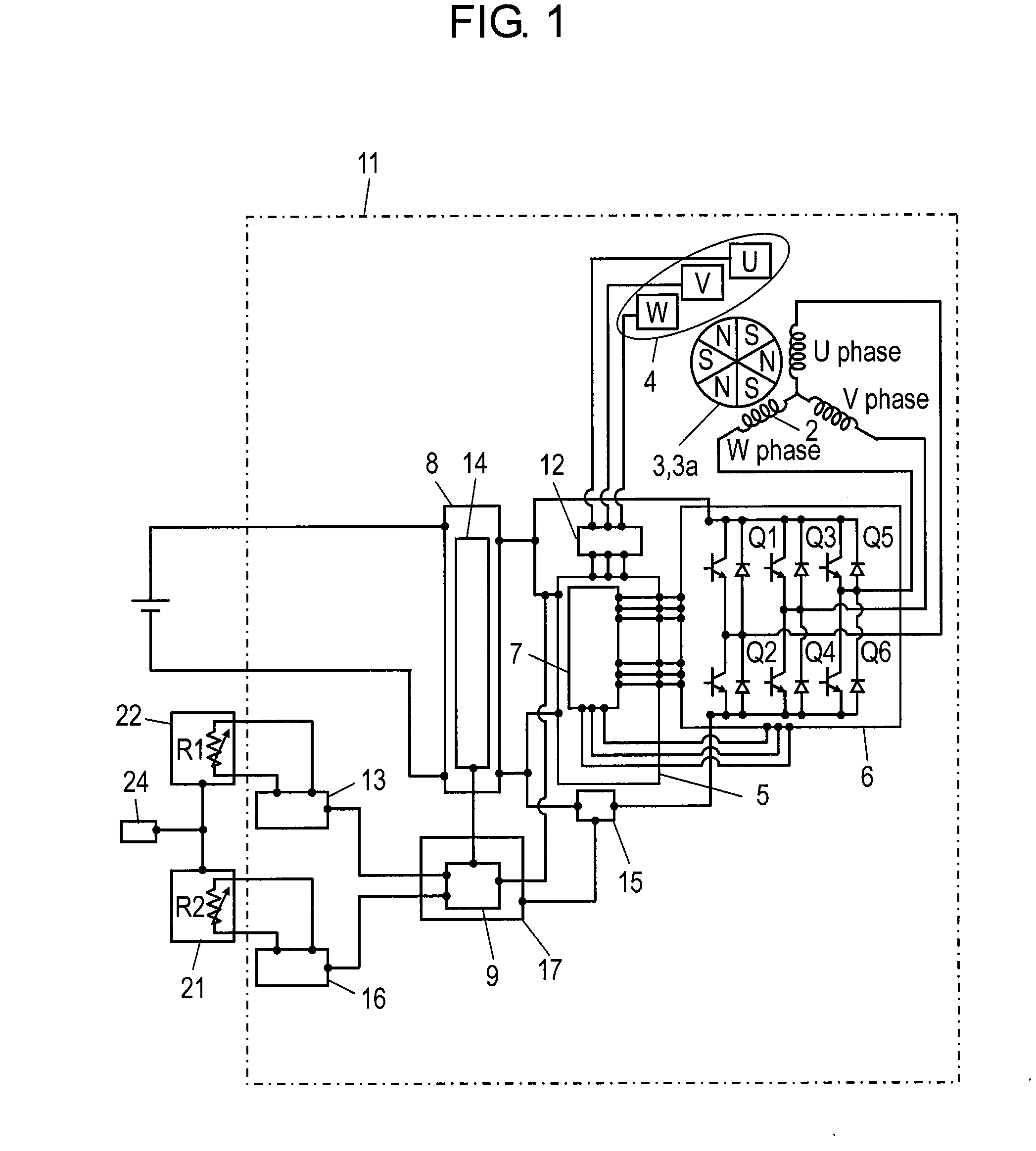

Electric motor and electrical apparatus equipped with same

InactiveUS20130257331A1High induced voltageAxial torque is increasedElectronic commutation motor controlMotor/generator/converter stoppersReference currentAverage current

An electric motor includes a magnet rotor which is placed with an air gap interposed between it and a stator and has a magnetic pole portion formed from a plastic magnet which swells by hydrogen bonds, an inverter circuit, a DC-voltage conversion portion, a driving logic control portion, a supply current value control portion, a current value designation portion, a reference current value designation portion, and a correlation designation portion, wherein the correlation designation portion determines an average current value by changing the average current value linearly or non-linearly with respect to a reference current value, and the magnetic pole portion absorbs moisture to swell, thereby making the air gap smaller, at higher humidity than a reference humidity.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

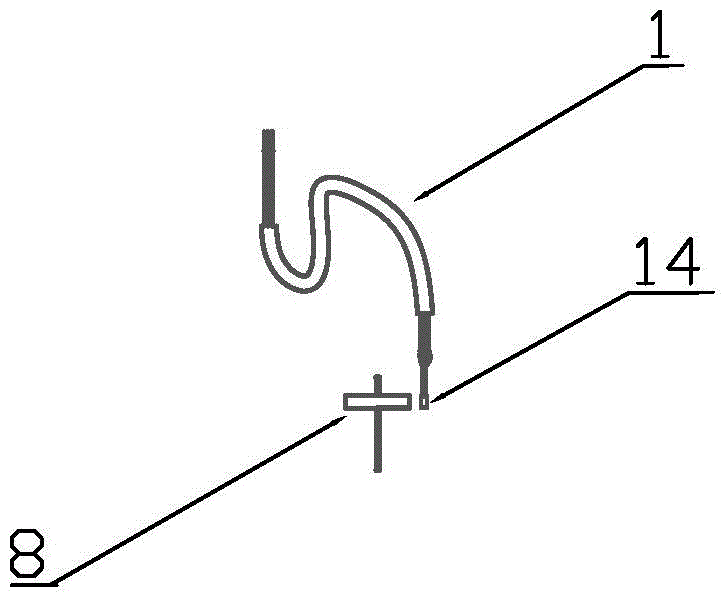

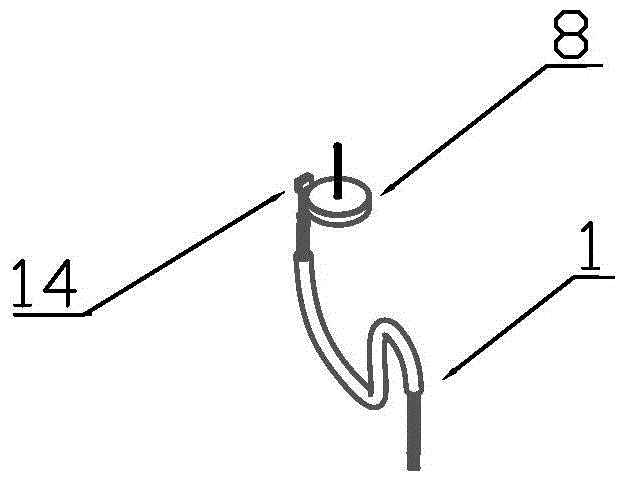

Liquid level detecting device

ActiveUS20180348037A1Improve detection accuracyImprove corrosion resistanceMachines/enginesLubrication indication devicesHall elementEngineering

A liquid level detecting device includes a sensor housing, a holder which is held rotatably by the sensor housing, a float arm which is fixed to the holder, a float which is attached to a tip portion of the float arm and varies in position following a surface level of liquid stored in a tank, a magnet provided in the holder, and a Hall element which is provided in the sensor housing and detects a displacement of the magnet of the holder. The magnet is a plastic magnet in which magnetic powder and a resin are mixed. A surface of the plastic magnet is coated by a coating layer.

Owner:YAZAKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com