Rotary flow-crossover valve

A switching valve, rotary technology, applied in the field of rotary process switching valves, can solve problems such as damage to the simplicity and durability of valve components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

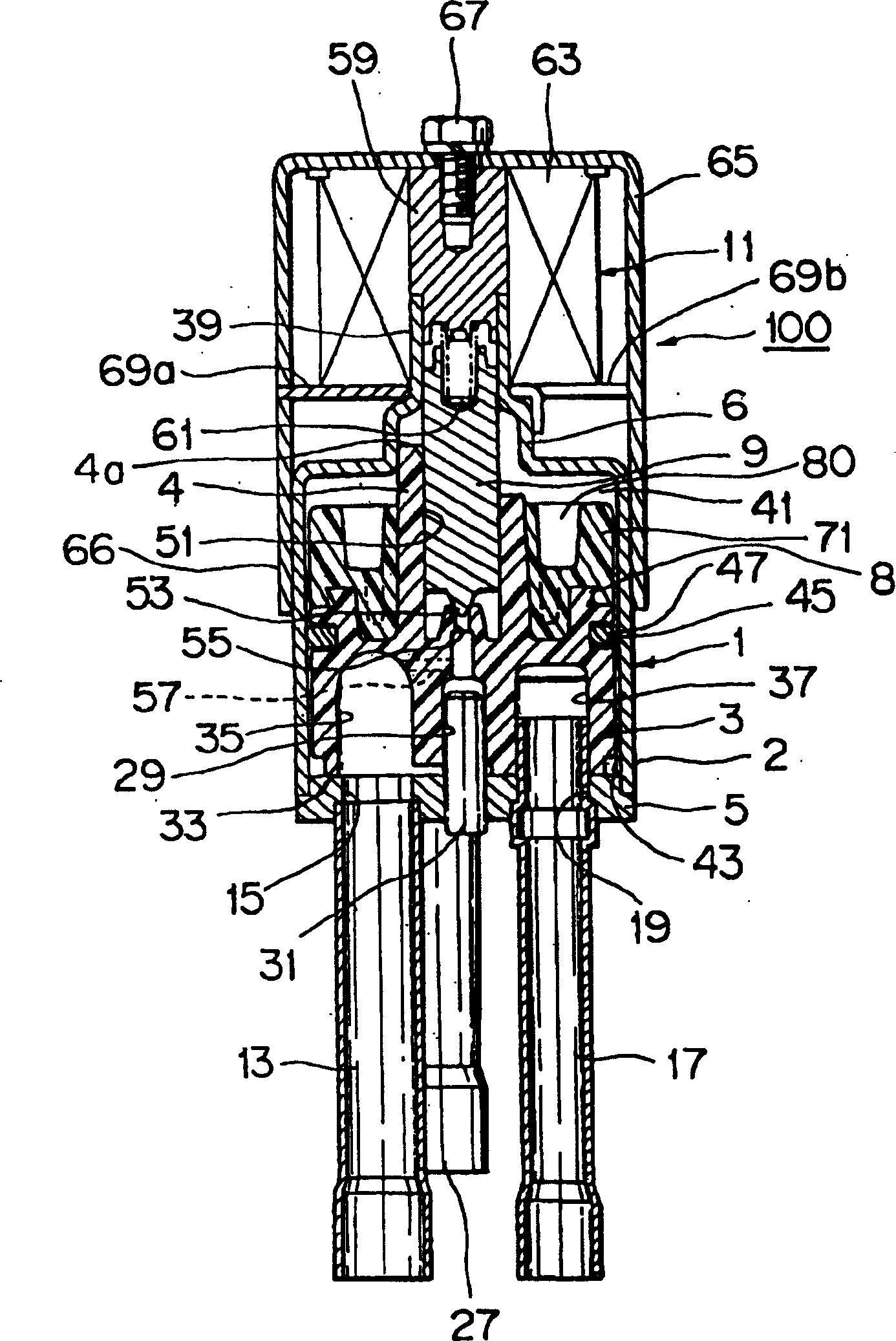

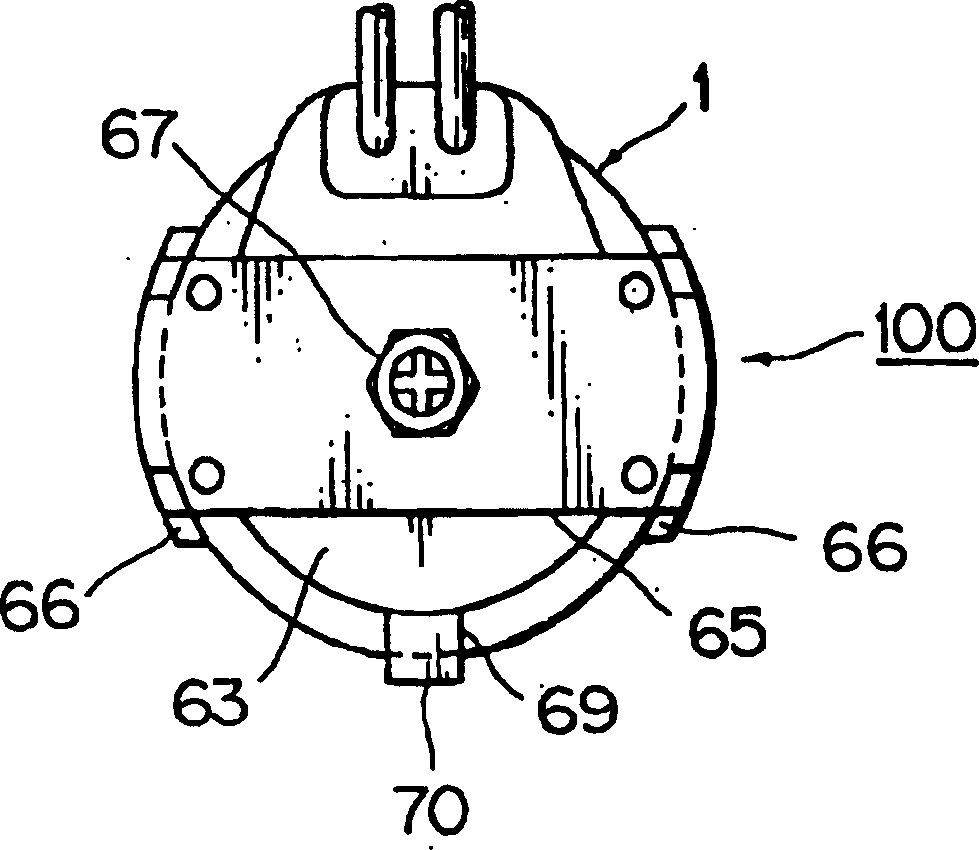

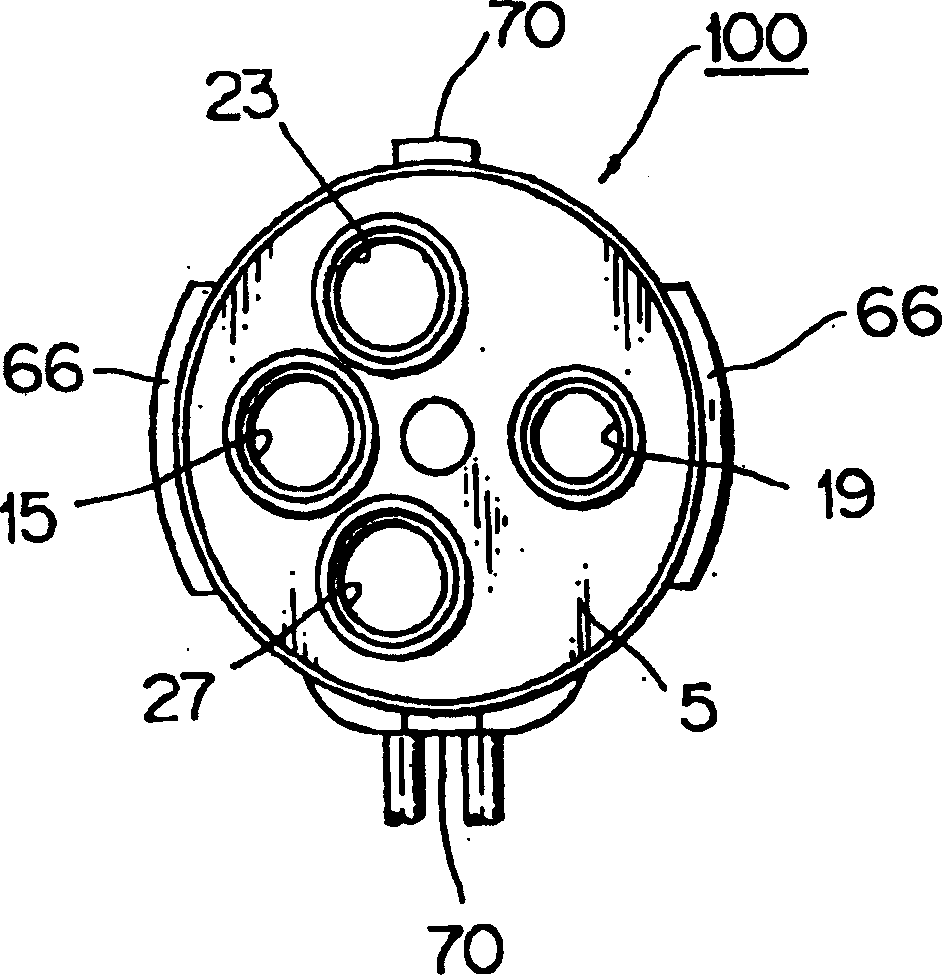

[0045] Reference now Figure 1 to 10 To explain the structure of the process exchange valve according to the embodiment of the present invention.

[0046] According to this embodiment, the rotary process exchange valve includes: a cylindrical valve housing 1, a main valve element 3 that can rotate and move in the direction of the rotation axis, a valve seat plate 5 fixed at the bottom of the valve housing 1, and a sliding The valve 9 and the solenoid 11 connected to the upper part of the valve housing 1.

[0047] As from Figure 5 As seen in 6, the structure of the rotary flow exchange valve is similar to the four-way valve 100 used in the steam pump system. In the position moved radially from its center, the valve seat plate 5 has: a low pressure port 15 with a low pressure pipe 13, which is connected from the suction side of the compressor P in the steam pump system; with a high pressure side The high pressure port 19 of the pipe 17, the pipe 17 is connected from the pressure re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com