Composition for synthetic resin composition and formed resin magnet

A technology of synthetic resin and magnetic body, which is applied in the field of resin magnetic body and synthetic resin magnetic body composition, and can solve problems such as under-injection and poor flow characteristics of resin compound melt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Magnetic powder having an average particle diameter of 100 μm can be produced by pulverizing General Motors Inc. with a composition of Nd 12 Fe 78 co 4 B 6 (Atomic weight %) Nd-based rare earth alloy "MQP-B" to prepare.

[0056] The magnetic powder can be surface-treated with "A1100" type silane coupling agent manufactured by Nippon Unicar Co., Ltd.

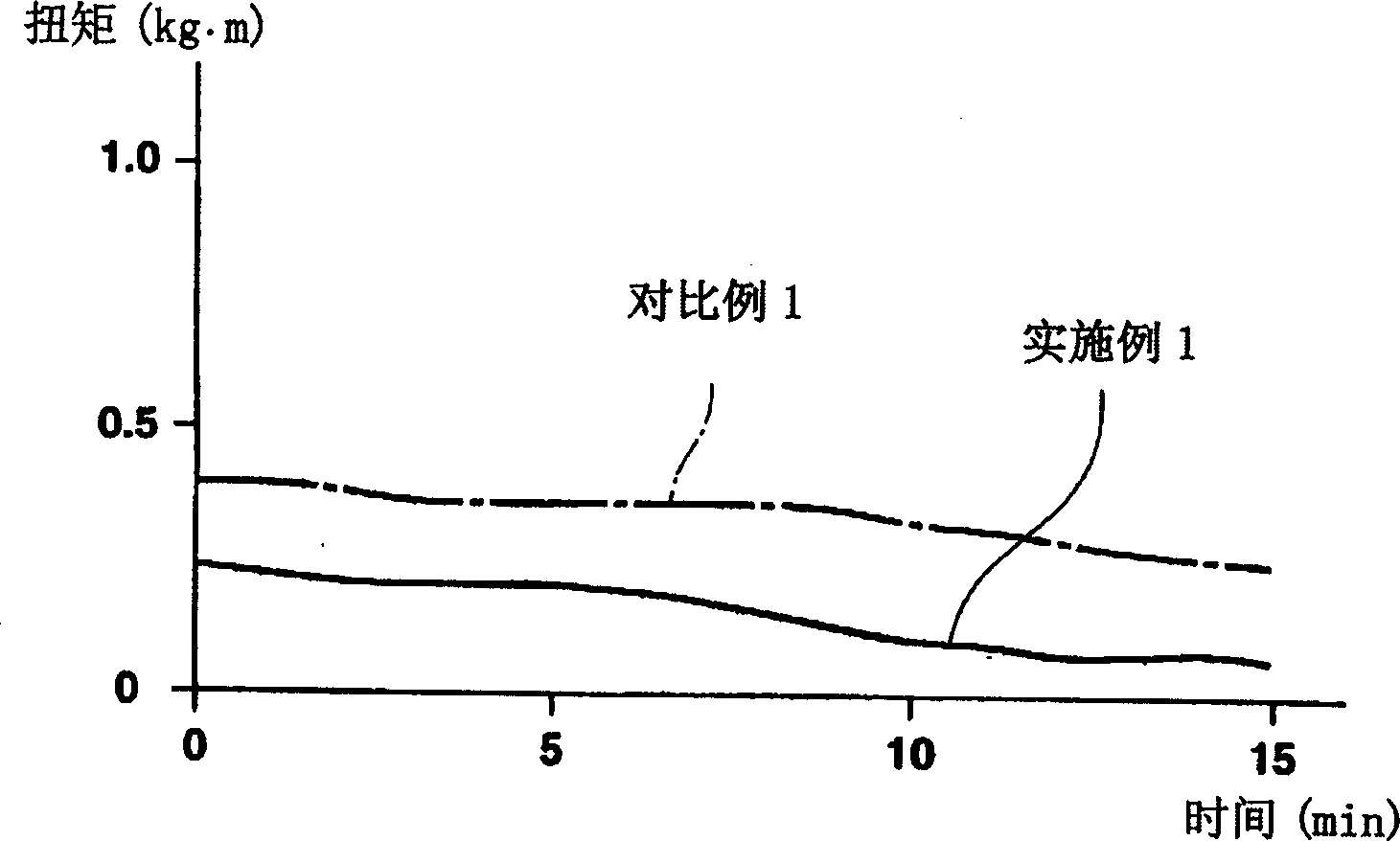

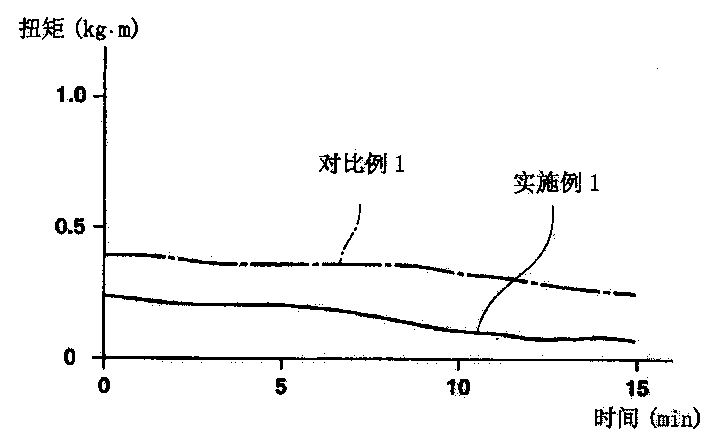

[0057] The following components were used at 250°C using "LaboPlastomill, Model 50C150" manufactured by Toyo Seiki Co., Ltd. (capacity 60cm 3 ), mixed for 15 minutes at a rotational speed of 50 rpm. Magnetic powder: 188 g (above); Nylon-12: "P 3012 U" 6.8 g, produced by Ube Industries. Ltd.; antioxidant: "IRGANOX MD 1024" 3.5 g, produced by Ciba Specialty Chemicals K.K.; aliphatic polyamide: "PA - 30L" 1.7g, manufactured by Fuji Kasei Co., Ltd. Thus, the synthetic resin magnetic composition according to the 1st invention and the 2nd invention of this application can be obtained. During melt mixing, changes in melt t...

Embodiment 2

[0062] The surface-treated magnetic powder was prepared with the following components. Sr ferrite: "NF110" 50.00kg, produced by Nippon Bengara Kogyo Co., Ltd.; Ba ferrite: "DNP-S" 20.55kg, produced by Nippon Bengara Kogyo Co., Ltd.; silane coupling agent: " A1100" 0.71kg, produced by Nippon Unicar Co., Ltd.

[0063] The resulting magnetic powder was mixed with the following components by a twin-screw mixer. Nylon-6: "P1010" 12.5 kg, produced by Ube Industries. Ltd.; antioxidant: "IRGANOX" 0.42 kg, produced by Ciba Specialty Chemical K.K.; aliphatic polyamide: "PA-30L" 0.42 kg, Fuji Kasei Co., Ltd. . Production; the obtained mixture is made into particles of the synthetic resin magnetic body composition of the first invention of the present application.

[0064] The melt flow rate (MFR) of the obtained synthetic resin magnetic composition was measured using a melt indexer (manufactured by Toyo Seiki Co., Ltd.). The MFR was found to be 156.84 g / 10 min (270°C, 5 kgf), a value ...

Embodiment 3

[0068] Magnetic powder with an average particle diameter of 50 μm can be composed of Nd by crushing 12 Fe 78 co 4 B 6 (atomic weight %) of a Nd-based rare earth alloy (“MQP-B”, having an average particle diameter of 50 μm, produced by General Motors Inc.). The magnetic powder was surface-treated with a "A1100" type silane coupling agent manufactured by Nippon Unicar Co., Ltd. The following components are mixed with a single-screw mixer, magnetic powder: 1880 g (above); Nylon-12 as a binder: 120 g, "P 3012U" produced by Ube Industries.Ltd; N, N'-di[3 - (3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hydrazine (hindered powder antioxidant): 50 g, type "IRGANOX MD1024" produced by Ciba Specialty Chemicals K.K.

[0069] The resulting mixture was made into pellets of the desired resin mixture (pellet shape) with plastic magnetic bodies. The resulting resin composite was found to have an MFR of 185 g / 10 min (250° C., 5 kgf). The synthetic resin magnetic body composition was injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com