Magnetic encoder, and production method therefor

A technology of a magnetic encoder and a manufacturing method, applied in the field of magnetic encoders, can solve problems such as shortening the takt time, and achieve the effects of low price, shortened takt time, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] [Examples 1 to 5, Comparative Example 1]

[0082] (production of test body)

[0083] First, polyamide 12, 30% by mass of a soft component (polyamide-based thermoplastic elastomer) and 0.5% by mass of a heat stabilizer (N,N'- Diphenyl-p-phenylenediamine), mixed to obtain a resin composition. Mixing was carried out at 250°C for 5 minutes. Then, the resin composition is pelletized by a usual method.

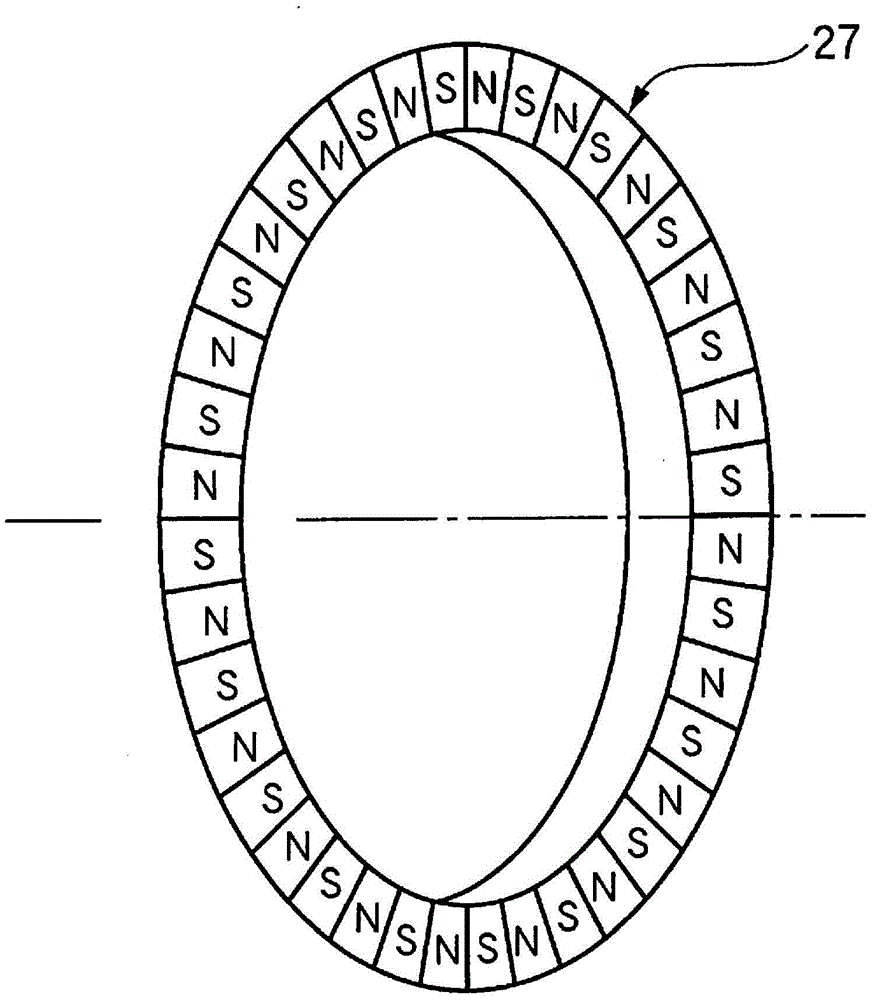

[0084] Next, ferrite magnetic powder was put into the pellets of the resin composition, and extruded after kneading at 250° C. for 10 minutes using a twin-screw extruder. It should be noted that the magnetic powder is 60% by volume of the plastic magnet material. Then, the extruded magnetic powder-containing resin composition is pelletized.

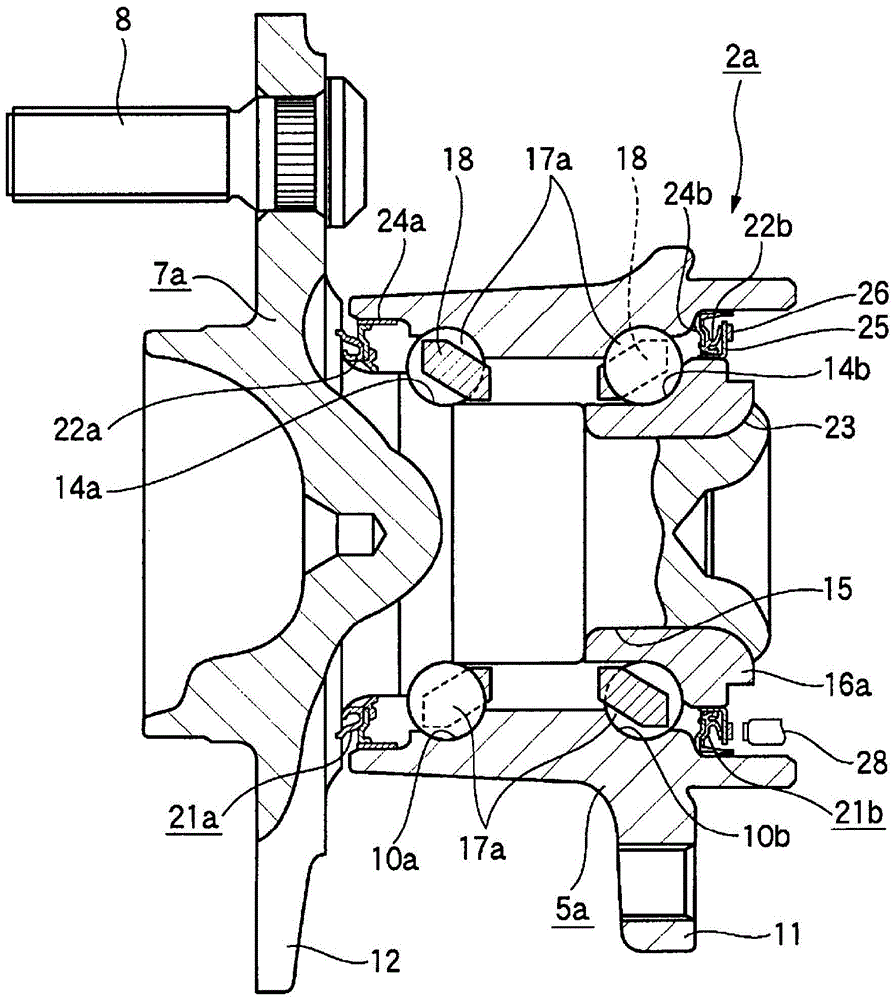

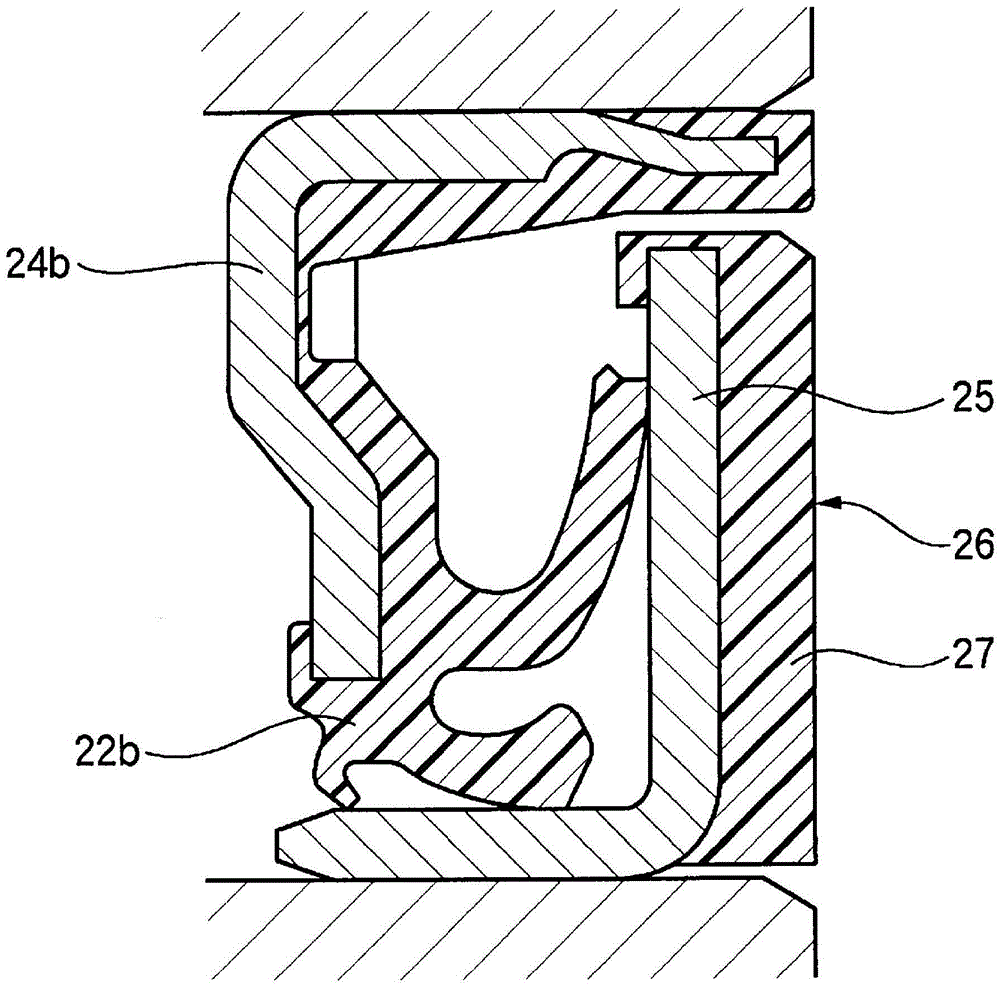

[0085] In addition, prepare a stainless steel flinger with an L-shaped cross section (refer to figure 2 ), use sandblasting to roughen the bonding surface.

[0086] Then, the adhesive shown in Table 1 was applied to the bonding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com