Motor rotor

A technology for electric motors and rotors, applied in the manufacture of stator/rotor bodies, synchronous motors with stationary armatures and rotating magnets, electromechanical devices, etc., can solve the problems of increased component costs and troublesome assembly operations, and achieve cost reduction and assembly Easier, torque-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] (first embodiment)

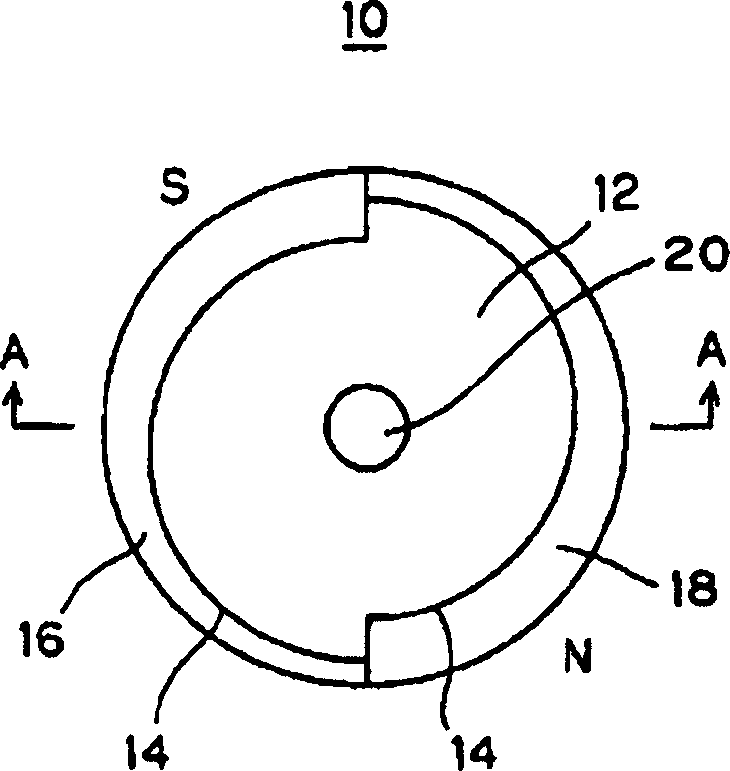

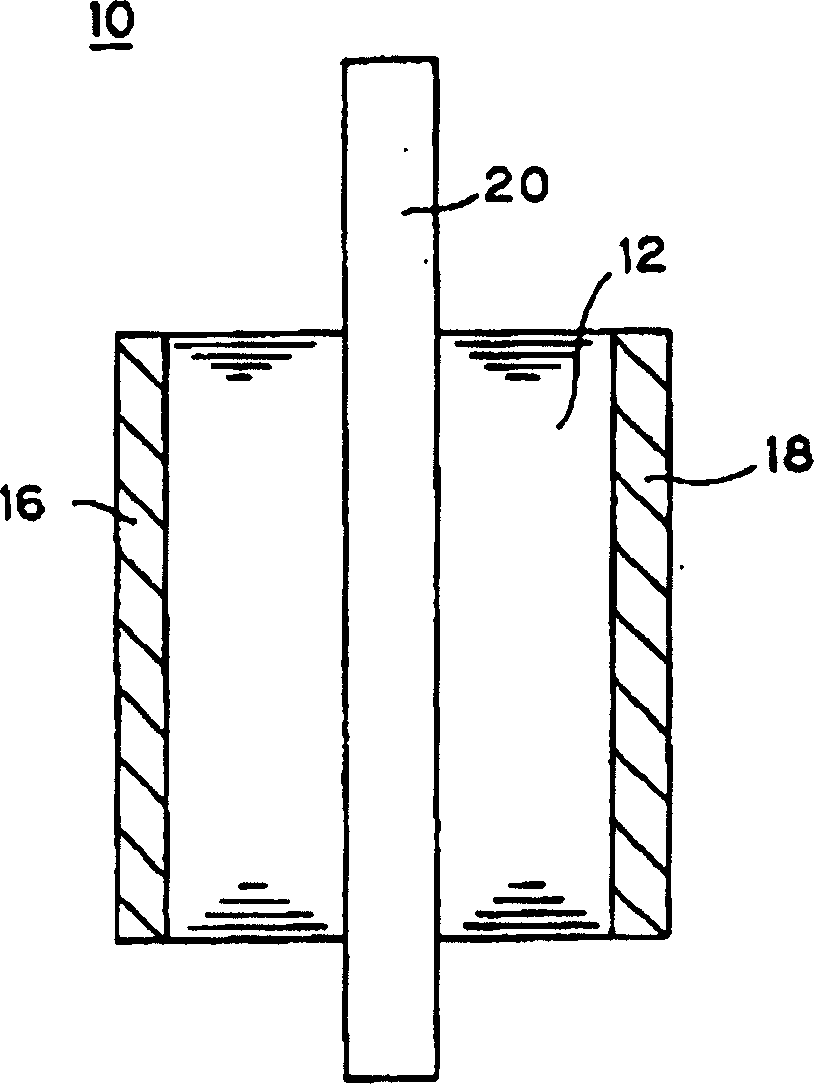

[0022] Below, refer to figure 1 and figure 2 The rotor 10 according to the first embodiment of the present invention will be described.

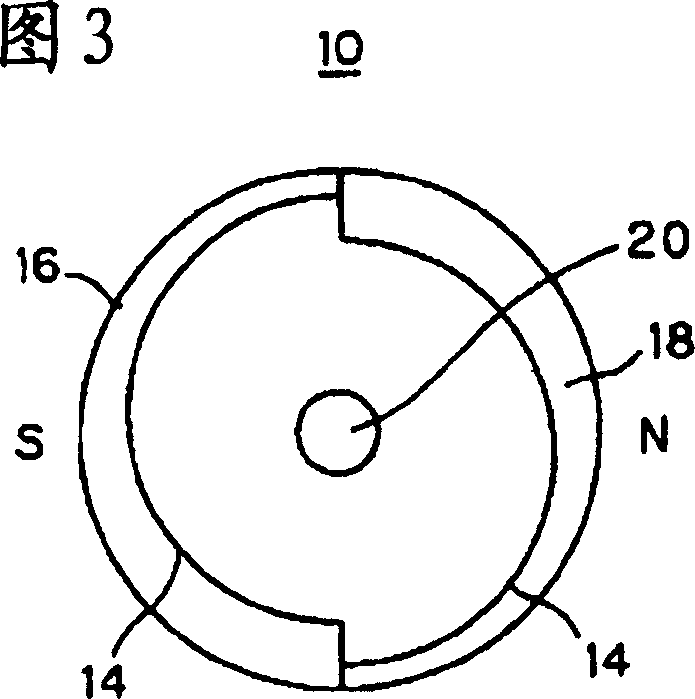

[0023] The rotor 10 of the present embodiment is a rotor of a single-phase synchronous motor, and has a two-pole configuration of an S pole and an N pole.

[0024] The structure of the rotor 10 will be described together with the manufacturing method.

[0025] As a first manufacturing process, steel plates are laminated and caulked to manufacture the rotor core 12 . Here, if figure 1 As shown, when the planar shape of the rotor core 12 is divided into left and right with the rotation axis as the center, the left part has an arc shape that is eccentric with respect to the rotation axis, and the right part is eccentric in a direction different from the left part. Oval. And, two spiral recesses 14, 14 are provided by this eccentricity.

[0026] As a second manufacturing process, the rotor core 12 is housed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com