Manufacture and raw material powder of anisotropic magnetic powder and plastics magnet

An anisotropic magnetic and manufacturing method technology, applied in the direction of inductance/transformer/magnet manufacturing, magnetic materials, magnetic objects, etc., can solve the problem of inability to obtain stable heat-resistant permanent magnets, unstable permanent demagnetization rate, and anisotropy Problems such as magnetic powder performance and quality instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

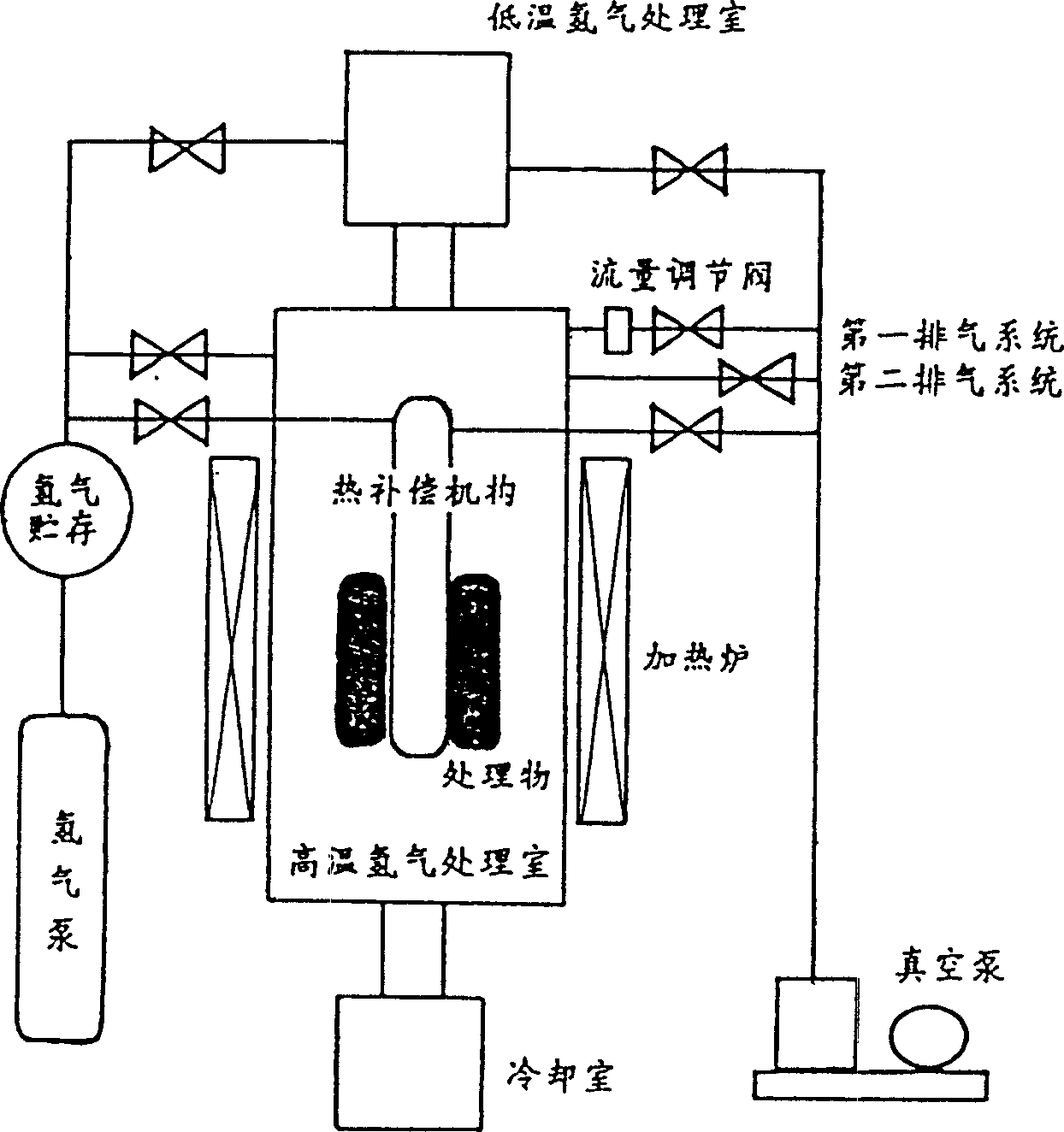

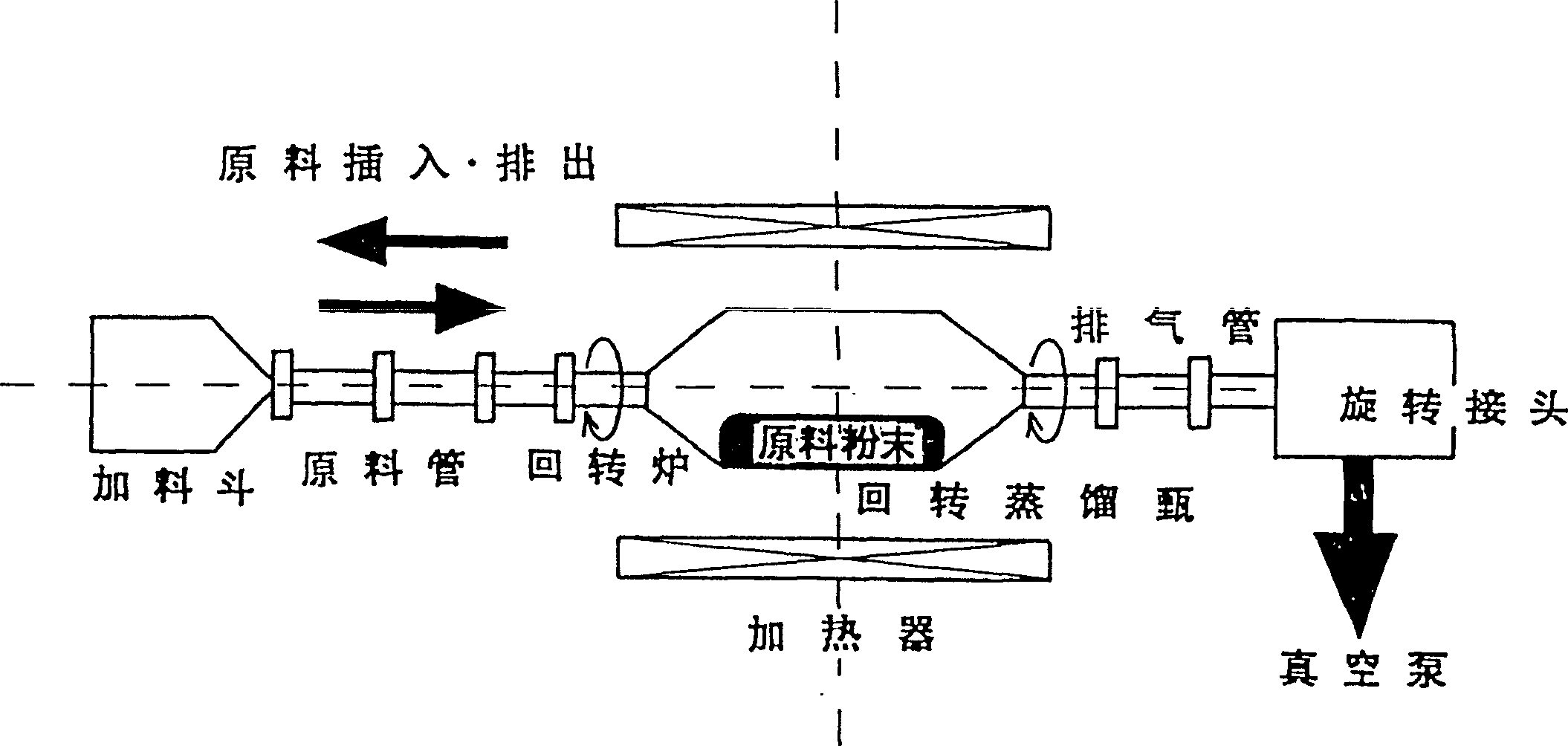

Method used

Image

Examples

Embodiment 1

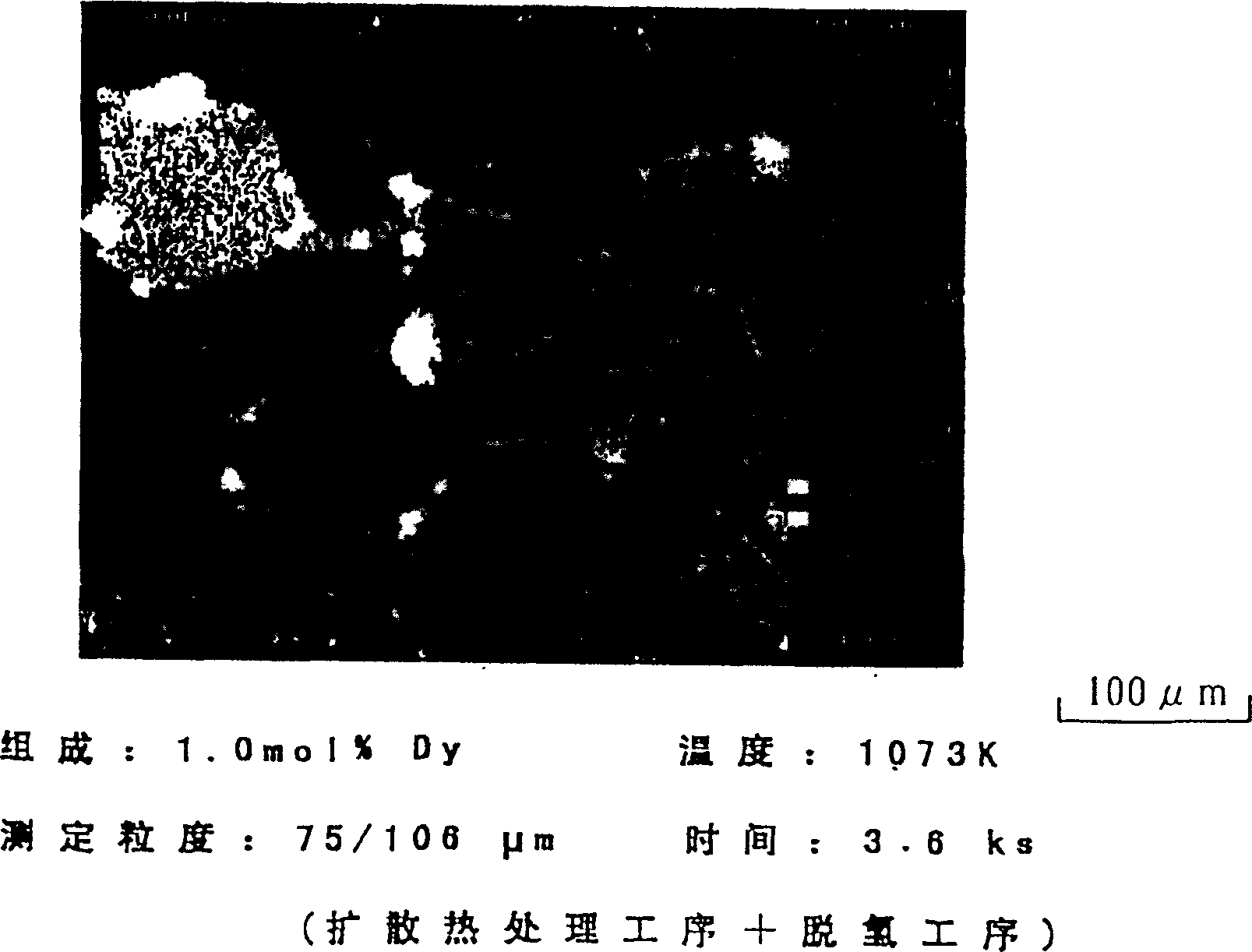

[0107] Example 1 (sample No.1-1 to 1-4)

[0108] (1) Manufacture of raw material powder for anisotropic magnetic powder

[0109] ①RFeB series material (for sample A)

[0110] With the composition of A shown in Table 1, the raw material alloy or raw material elements were quantitatively weighed and dissolved using a high-frequency melting furnace to produce a 100 kg alloy ingot. Also, Table 1 is a table showing the content of each element in at% when the entire alloy is taken as 100 at% (atoms).

[0111] Thereafter, this alloy ingot was heat-treated at 1140° C. for 40 hours in an argon (Ar gas) atmosphere to homogenize the structure of the alloy ingot. In addition, the homogenized alloy ingot was pulverized into a coarse powder with an average particle diameter of 10 mm or less with a jaw crusher, and this was used as a sample of the RFeB-based material.

[0112] ②Low temperature hydrogenation process

[0113] Take 10kg of coarsely crushed RFeB-based materials (coarsely cru...

Embodiment 2

[0129] Example 2 (sample No.2-1)

[0130] A strip having the same composition (composition A) as in Example 1 was manufactured according to the steel casting method, and it was used as a sample. For this sample, the same steps as in Example 1 were carried out under the conditions shown in Table 2 to produce anisotropic magnetic powder.

Embodiment 3

[0131] Example 3 (sample No.3-1 to 3-3)

[0132] An RFeB-based material composed of the composition B shown in Table 1 was used as a sample, and the anisotropic magnetic powder was produced using this sample under the conditions shown in Table 2 in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com