Buzzer automatic assembling machine

An automatic assembly machine and buzzer technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of high price, poor stability, and difficult welding of buzzers, so as to improve the degree of automation, The effect of high product quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following examples of the present invention is based on the vision inspiration, the contents of the following description, relevant staff can without departing from the scope of the technical ideas of the present inventions, a variety of changes and modifications. The technical scope of this invention is not limited to the instructions, and the technical range must be determined according to the claim scope.

[0043] Reference to the following drawings, the present invention will be further described:

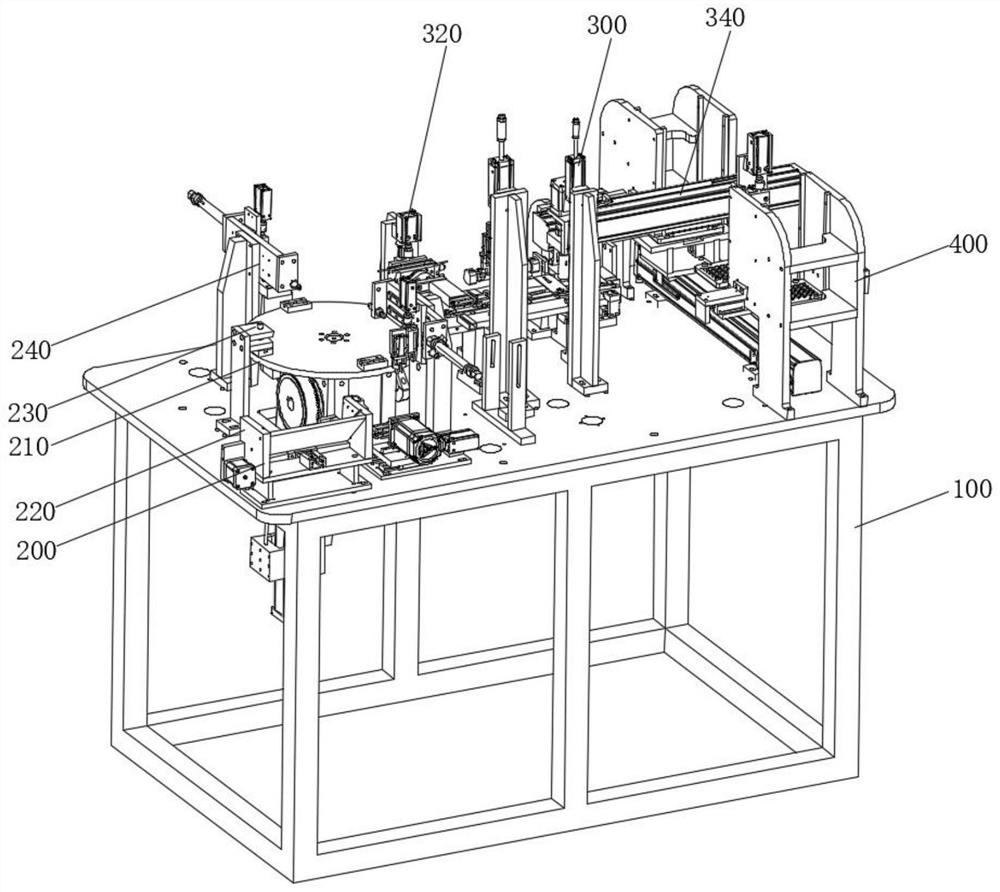

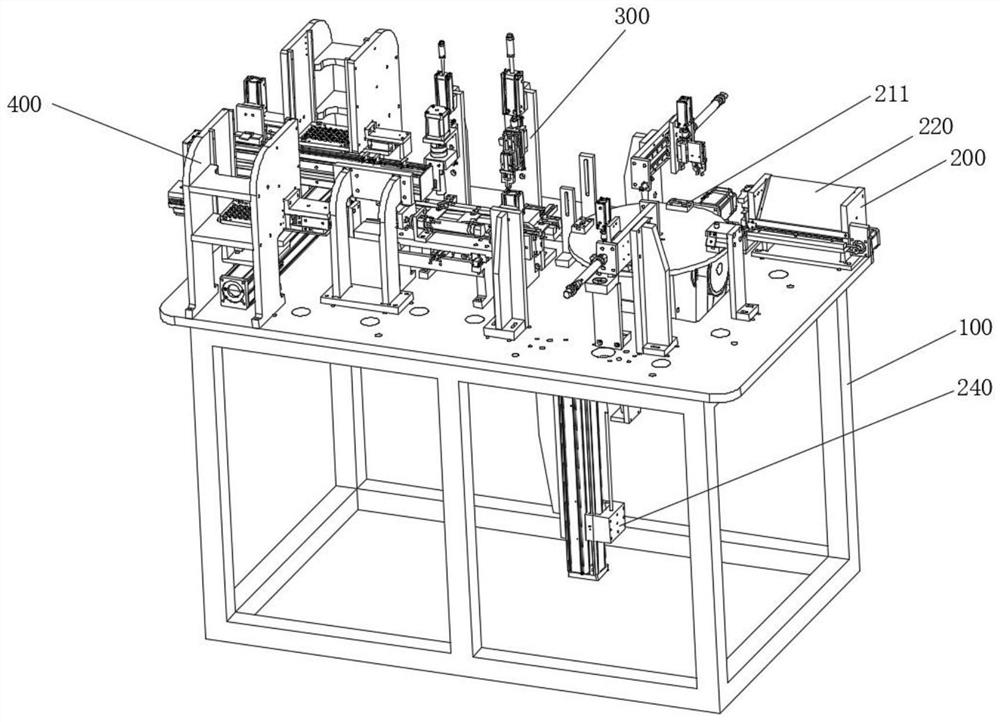

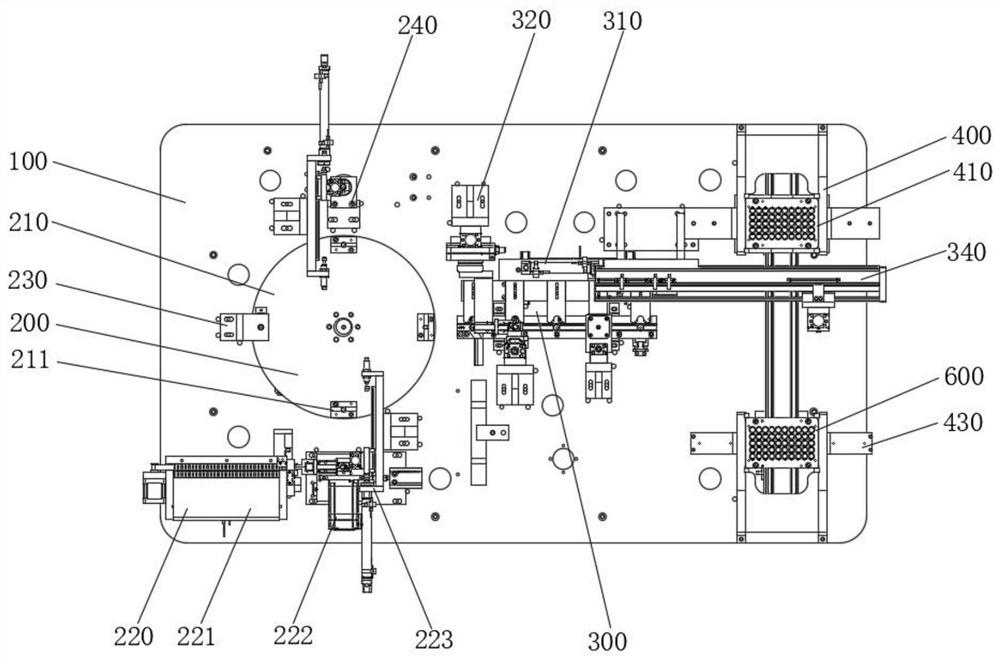

[0044] like Figure 1 ~ 16 As shown in A buzzer automatic assembly machine, comprising a stage 100, the stage 100 is provided on the component feeding module 200, module assembly 300 and a receipt module 400.

[0045] like Figure 5 , 6 , 7 and 8, the upper part 200 includes a turntable 210 feeding modules and feed mechanism 210 are sequentially disposed along the dial ring 220, and the loading detection unit 230 buzzer 240 magnetic feeding mechanism feeding mechanism 220 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com