Binder for producing carbon-containing pellets, carbon-containing pellets and preparation method thereof

A technology of binder and carbon pellets, which is applied in the field of binders for the production of carbon-containing pellets from laterite nickel ore, can solve the problem of production cost, great impact on economic benefits, impact on energy consumption and output of reduction, and impact on the iron grade of raw materials. and other problems, to achieve the effect of improving the direct reduction effect, large production capacity, falling strength and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Raw materials: Laterite nickel ore is the secondary tailings of copper smelting tailings after copper separation, with a particle size of ~200 mesh and a water content of ~15%, that is, the content of laterite nickel ore is >85%; the particle size of reduced coal and limestone is 200 The water content is about 10%, that is, the content of reduced coal and limestone is more than 70%.

[0030] Mix laterite nickel ore, reduced coal, limestone, and bentonite in proportion, the proportion is 100:27:14:2.5; mix starch, caustic soda and water in proportion, dissolve and stir for 25 minutes, the proportion is 0.5:0.05:6; The compared materials are sent to a strong mixer, and the mixing time is 3 minutes to obtain a mixture; the mixture is sent to a briquetting machine to produce wet carbon-containing pellets and dried.

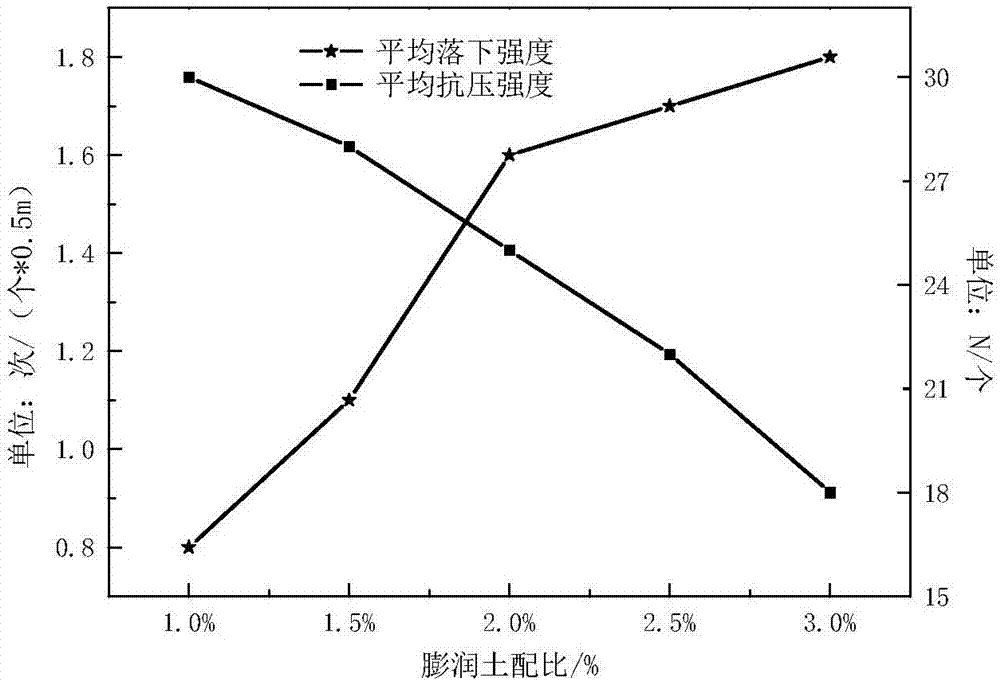

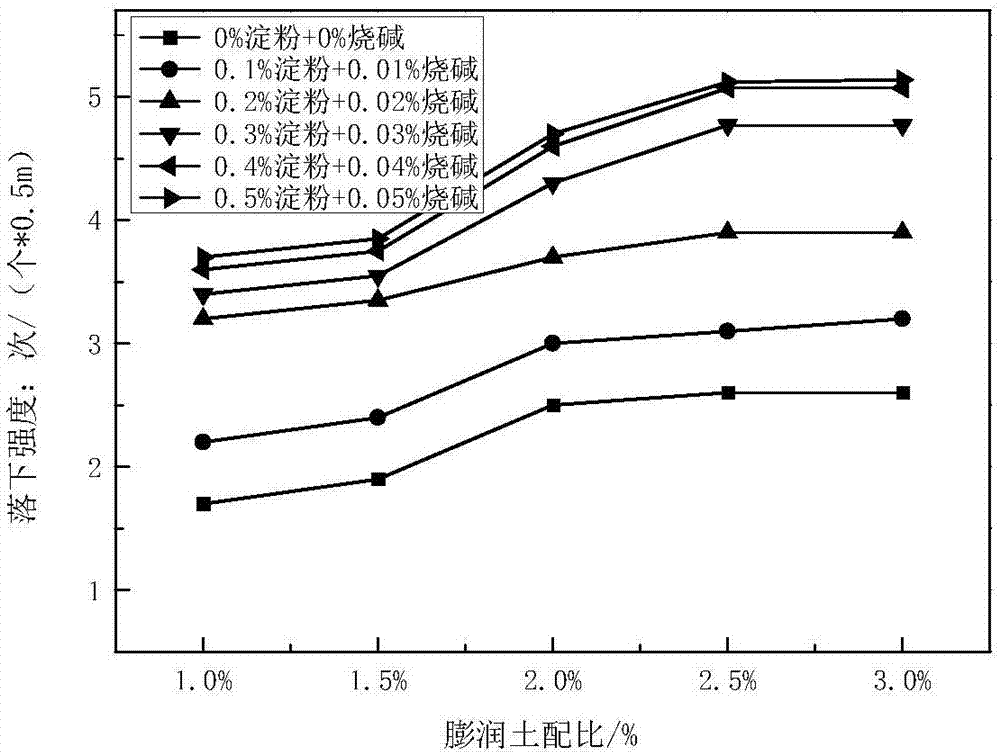

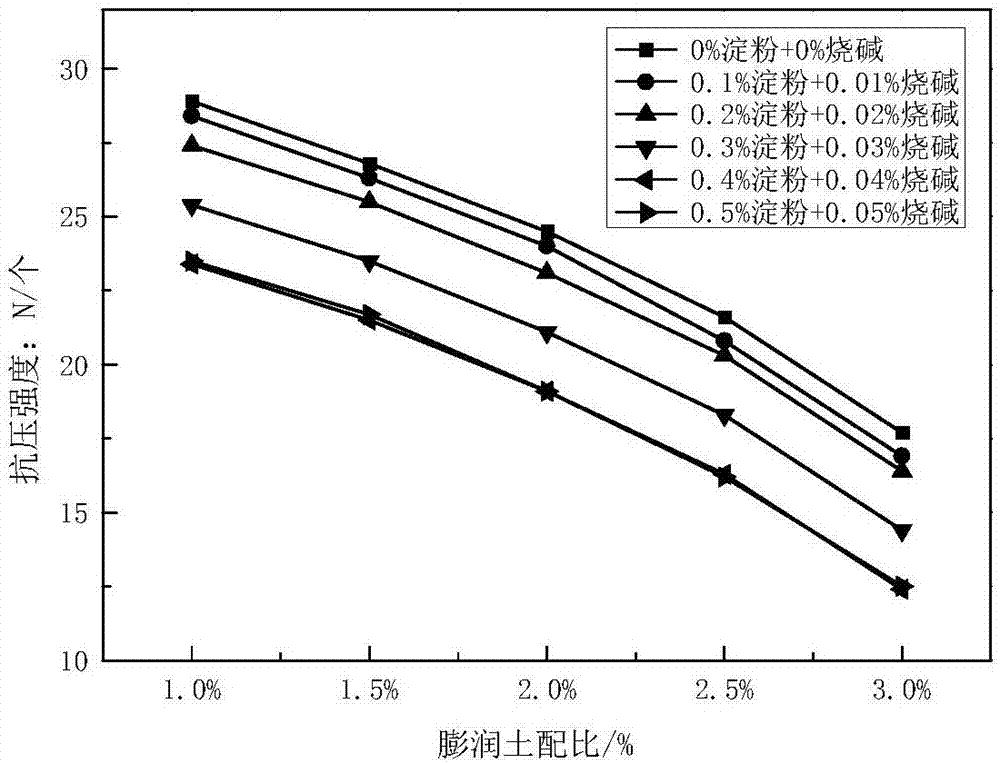

[0031] The prepared carbon-containing pellets are elliptical and have a particle size of 20×30×40 mm. The average drop strength of carbon-containing pellets i...

Embodiment 2

[0033] Raw material is with embodiment 1.

[0034] Mix laterite nickel ore, reduced coal, limestone, and bentonite in a proportion of 100:27:14:2; mix starch, caustic soda and water in proportion, dissolve and stir for 25 minutes, and the proportion is 0.4:0.04:6; The compared materials are sent to a strong mixer, and the mixing time is 3 minutes to obtain a mixture; the mixture is sent to a briquetting machine to produce wet carbon-containing pellets and dried.

[0035] The prepared carbon-containing pellets are elliptical and have a particle size of 20×30×40 mm. The average drop strength of carbon-containing pellets is 4.30 times / (piece·0.5m), and the average compressive strength is about 21.1N / piece.

Embodiment 3

[0037] Raw material is with embodiment 1.

[0038]Mix laterite nickel ore, reduced coal, limestone, and bentonite in a proportion of 100:27:14:1.5; mix starch, caustic soda and water in proportion, dissolve and stir for 25 minutes, and the proportion is 0.3:0.03:6; The compared materials are sent to a strong mixer, and the mixing time is 3 minutes to obtain a mixture; the mixture is sent to a briquetting machine to produce wet carbon-containing pellets and dried.

[0039] The prepared carbon-containing pellets are elliptical and have a particle size of 20×30×40 mm. The average drop strength of carbon-containing pellets is 3.35 times / (piece·0.5m), and the average compressive strength is about 25.5N / piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com