A kind of processing method of sorghum stalk particleboard

A processing method and technology of sorghum stalks, applied in the field of sorghum stalk particleboard processing, can solve the problems of high health threats to workers, variable quality of finished products, complicated process, etc., to improve physical and mechanical properties, surface smoothness and fineness , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

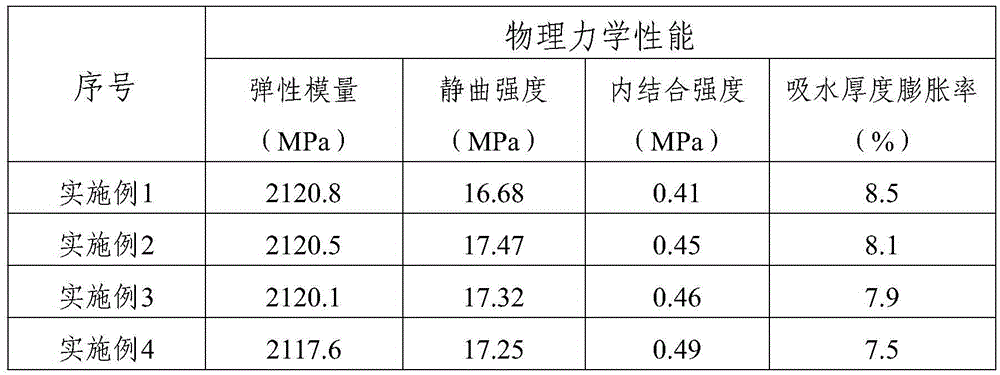

Examples

Embodiment 1

[0029] Take some fresh sorghum stalks with leaves removed, slice the sorghum stalks obliquely through a chipper, and the thickness of the slices is 2.5mm; sieve the slices through a sieving machine to remove the skin, midridge and mud in the slices; the sieved Sorghum stalk slices are shaved by a roller flaker, and the area is 6mm 2 flaky shavings; put the flaky shavings into a tumble dryer at 180°C for 40 minutes to dry, the drum speed is 20r / min, and the moisture content of the dried flaky shavings is 4.8%; the dried flaky The shavings are separated by a cyclone separator and sent to the warehouse for storage; respectively take 45kg of dried flaky shavings, 4kg of urea-formaldehyde resin glue, and 1kg of waterproofing agent and put them into the mixer to stir evenly to obtain a mixture. The solid content in the urea-formaldehyde resin glue 14.5%; Pour the stirred mixture into a pressing mold with an inner diameter of 150cm, first pour 1 / 3 of the weight of the mixture into th...

Embodiment 2

[0031] Take some fresh sorghum stalks with leaves removed, slice the sorghum stalks obliquely through a chipper, and the thickness of the slices is 2.8mm; sieve the slices through a sieving machine to remove the skin, midridge and mud in the slices; the sieved Sorghum stalk slices are shaved by a roller flaker, and the area is 7mm 2 flaky shavings; put the flaky shavings into a tumble dryer at 190°C for 42 minutes, the drum speed is 30r / min, and the moisture content of the dried flaky shavings is 4.5%; the dried flaky The shavings are separated by a cyclone separator and sent to the warehouse for storage; respectively take 43.5kg of dried flaky shavings, 5kg of urea-formaldehyde resin glue, and 1.5kg of waterproofing agent and put them into the mixer to stir evenly to obtain a mixture, in which the urea-formaldehyde resin glue is solidified Content 13.5%; Pour the stirred mixture into a pressing mold with an inner diameter of 150cm, first pour 1 / 3 of the weight of the mixture ...

Embodiment 3

[0033] Take some fresh sorghum stalks with leaves removed, slice the sorghum stalks obliquely through a chipper, and the thickness of the slices is 3.0mm; sieve the slices through a sieving machine to remove the epidermis, midridge and mud in the slices; the sieved The sorghum stalks are sliced by a roller flaker, and the area is 7.6mm 2 flaky shavings; put the flaky shavings into a tumble dryer at 195°C for 44 minutes, the drum speed is 25r / min, and the moisture content of the dried flaky shavings is 4.6%; the dried flaky The shavings are separated by a cyclone separator and sent to the warehouse for storage; respectively take 44.1kg of dried flaky shavings, 4.5kg of urea-formaldehyde resin glue, and 1.4kg of waterproofing agent and put them into the mixer to stir evenly to obtain a mixture. Solid content 12.8%; Pour the stirred mixture into a pressing mold with an inner diameter of 150cm, first pour 1 / 3 weight of the mixture into the mold, spread it evenly, and then pour 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com