Preparation method of high-performance samarium-cobalt permanent magnetic material

A permanent magnet material, high-performance technology, used in magnetic materials, inductor/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of impurity gas, ash, and compactness of blanks and grain control product performance improvement defects, etc. Achieve the effect of saving energy and sintering time, reducing production costs and reducing the difficulty of sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

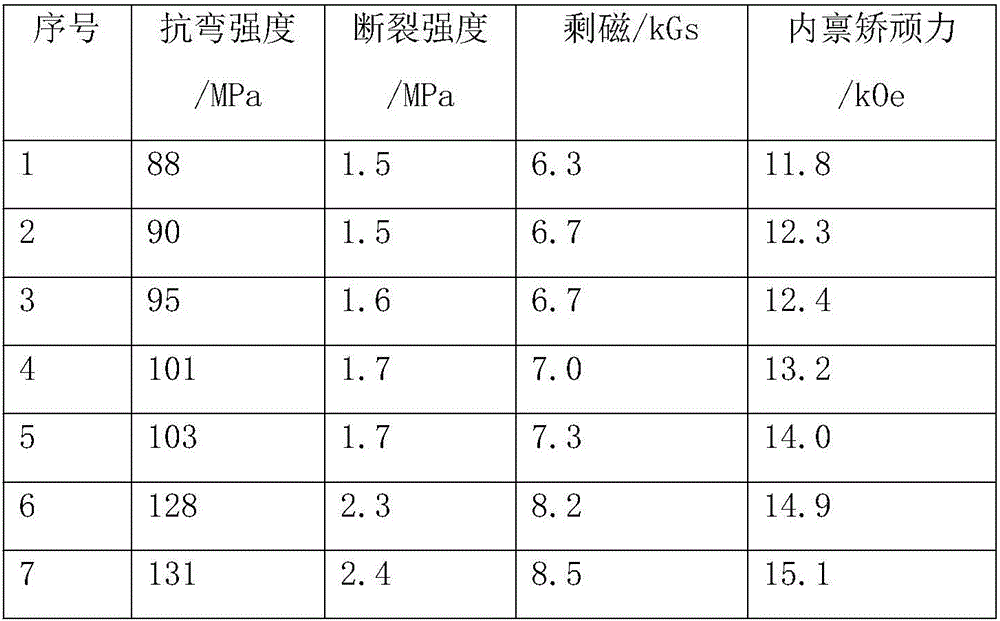

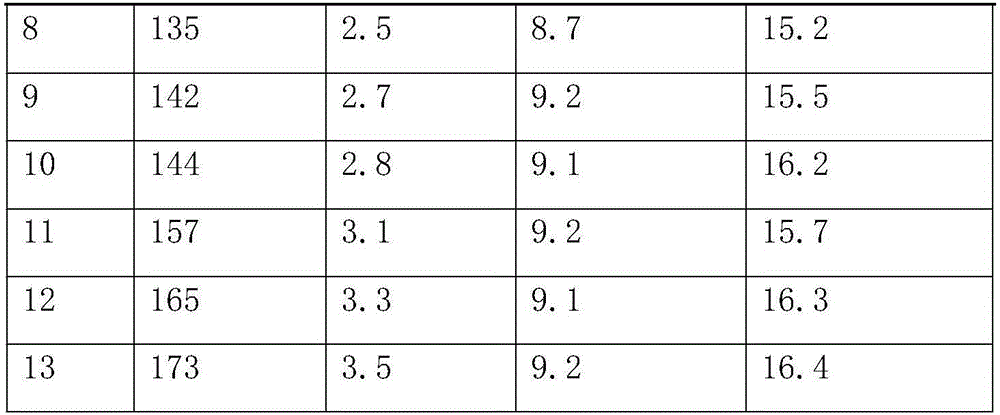

Embodiment 1

[0021] In this embodiment, the sintering is to degas and deash the green body obtained by orientation molding, pre-sintering, vacuum sintering, protective atmosphere sintering, and solid solution in sequence, wherein the pre-sintering is pre-sintering at 1050° C. for 20 Min.

Embodiment 2

[0023] In this embodiment, the sintering is to degas and deash the green body obtained by orientation molding, pre-sintering, vacuum sintering, protective atmosphere sintering, and solid solution in sequence, wherein the pre-sintering is pre-sintering at 1060° C. for 30 Min.

Embodiment 3

[0025] In this embodiment, the sintering is to degas and deash the green body obtained by the orientation molding, pre-sintering, vacuum sintering, protective atmosphere sintering, and solid solution in sequence, wherein the pre-sintering is pre-sintering at 1070° C. for 25 Min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com