Pulsating vacuum pressure steam sterilizer

A pressurized steam and pulsating vacuum technology, applied in the field of medical equipment, can solve the problems of increasing the working time of the sterilizer, losing the insulation effect of the jacket, and slow steam entering the inner chamber, so as to shorten the working time and reduce the degree of wetting , good warm-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

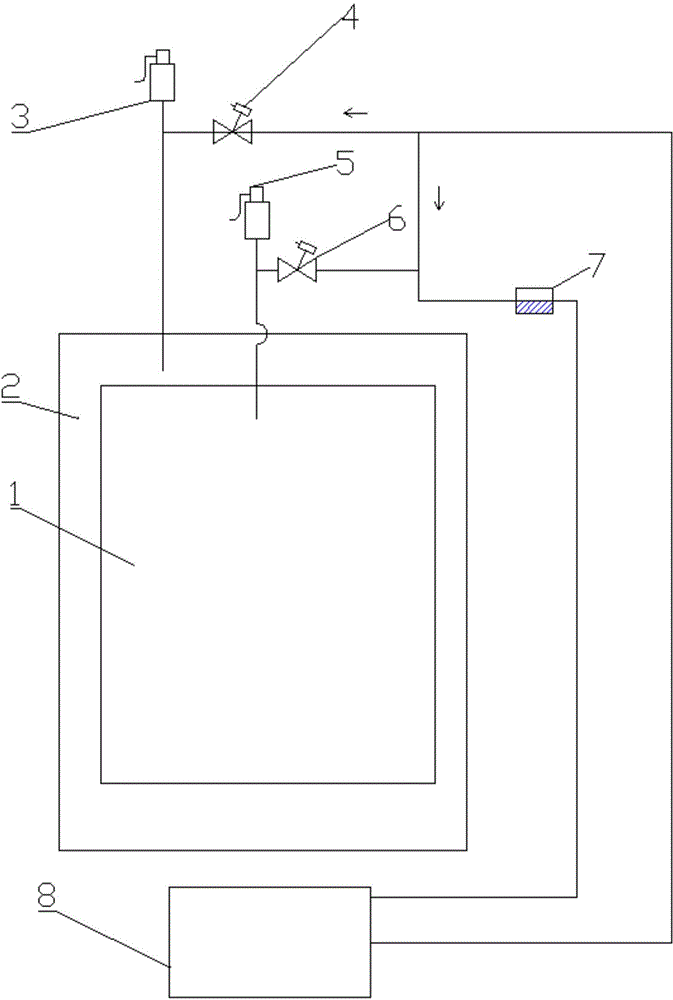

[0024] The pulsating vacuum pressure steam sterilizer as shown in the accompanying drawings includes an inner chamber 1, a jacket 2, and a steam inlet mechanism, wherein the steam inlet mechanism includes a jacket safety valve 3, a jacket air control angle seat valve 4, Inner chamber safety valve 5, inner chamber air control angle seat valve 6, steam trap 7, steam generator 8 and filter (not shown in the figure), wherein the jacket air control angle seat valve 4 is arranged between the jacket 2 and the steam Between the generators 8, and a jacket safety valve 3 is set in the jacket; the inner chamber air control angle seat valve 6 is arranged between the inner chamber 1 and the steam generator 8, and an inner chamber safety valve 5 is arranged in the inner chamber ; The steam generator 8 is arranged under the steam inlet mechanism, the steam inlet mechanism pipeline is provided with a steam trap 7, and the filter is arranged at the steam inlet end of the steam inlet mechanism; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com